- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Dec . 11, 2024 11:28 Back to list

drive belt suppliers

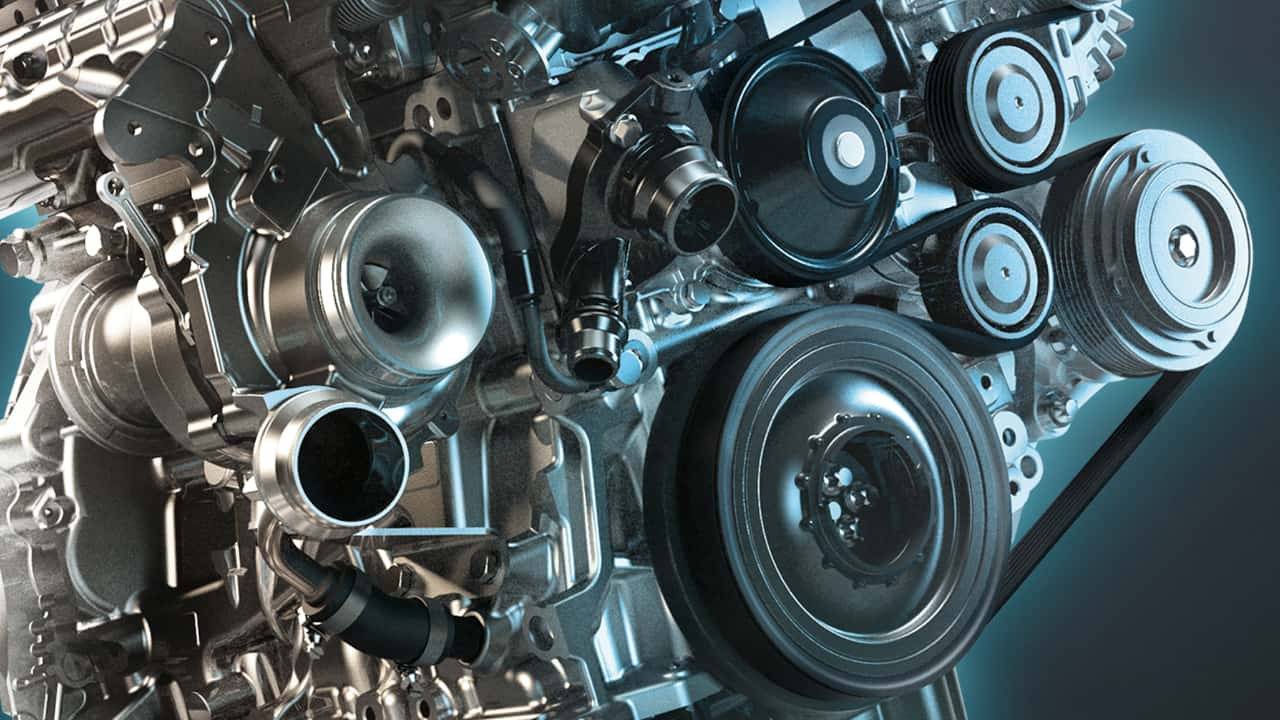

Understanding Drive Belt Suppliers An Overview

Drive belts are integral components in various mechanical systems, serving a crucial role in enabling motion transfer between different parts of machines, vehicles, and industrial equipment. The market for drive belts is vast and diverse, encompassing suppliers that offer an array of products tailored for different applications. This article aims to delve into the world of drive belt suppliers, discussing their significance, the types of belts available, and the factors to consider when selecting a reliable supplier.

The Importance of Drive Belts

Drive belts are essential in numerous applications, from automotive engines to industrial machinery. They are employed to power various components such as alternators, water pumps, and air conditioning systems in vehicles. In industrial settings, drive belts connect motors to conveyor systems or other types of machinery, facilitating the smooth operation of production lines.

The reliability and efficiency of these belts directly affect the performance of the equipment they support. A faulty or worn-out drive belt can lead to equipment failure, increased maintenance costs, and production downtimes. Therefore, sourcing high-quality drive belts from reputable suppliers is paramount for businesses and consumers alike.

Types of Drive Belts

Drive belts come in several types, each designed for specific functions and applications

. The most common varieties include1. V-Belts These are commonly used in various machinery and HVAC systems. Their wedge shape allows them to grip pulleys effectively, making them a popular choice for many mechanical applications.

2. Timing Belts Known for their precision in movement, timing belts are designed with teeth that fit into corresponding grooves on the pulleys. This design prevents slippage and ensures that engine components remain synchronized, making them essential in automotive engines.

3. Flat Belts Often used in light-duty applications, flat belts are simple and effective for connecting large pulleys over a substantial distance.

4. Round Belts These are more flexible than flat belts and are ideal for smaller, lighter applications, such as in small machinery or conveyor systems.

drive belt suppliers

5. Poly-V Belts Also known as serpentine belts, these belts have multiple grooves and are used in various automotive applications for their ability to transmit power efficiently under limited space.

Choosing the Right Supplier

When it comes to selecting a drive belt supplier, several factors should be considered to ensure you choose a partner who meets your needs effectively

1. Product Quality Quality should always be the foremost concern. Look for suppliers who offer products that comply with industry standards and are known for their durability and performance.

2. Range of Products A good supplier should provide a broad selection of drive belts to cater to different applications. This enables easier sourcing for businesses that require multiple types of belts or those that may seek customized solutions.

3. Technical Support Suppliers who offer robust technical support can provide valuable insights on product selection, installation guidance, and troubleshooting, helping businesses maintain efficient operations.

4. Delivery Reliability Timely delivery is crucial in minimizing downtime for businesses. A reputable supplier should have efficient logistics in place to ensure that products reach customers promptly.

5. Customer Reviews and Reputation Before finalizing a supplier, check their reputation in the industry. Reading customer reviews and testimonials can offer insights into the supplier's reliability and service quality.

6. Cost-Effectiveness While it is essential to obtain quality products, price also plays a significant role. Compare the pricing structures between different suppliers, but be cautious of options that seem too good to be true, as they may compromise quality.

Conclusion

Drive belt suppliers play a vital role in various industries by providing essential components that ensure the smooth functioning of machinery and vehicles. Understanding the types of belts available, as well as the critical factors in selecting a supplier, can lead to more informed decisions. By partnering with reliable suppliers, businesses can enhance their operational efficiency, reduce maintenance costs, and ensure that their equipment performs optimally.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025