- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Nov . 16, 2024 14:00 Back to list

belt v-ribbed

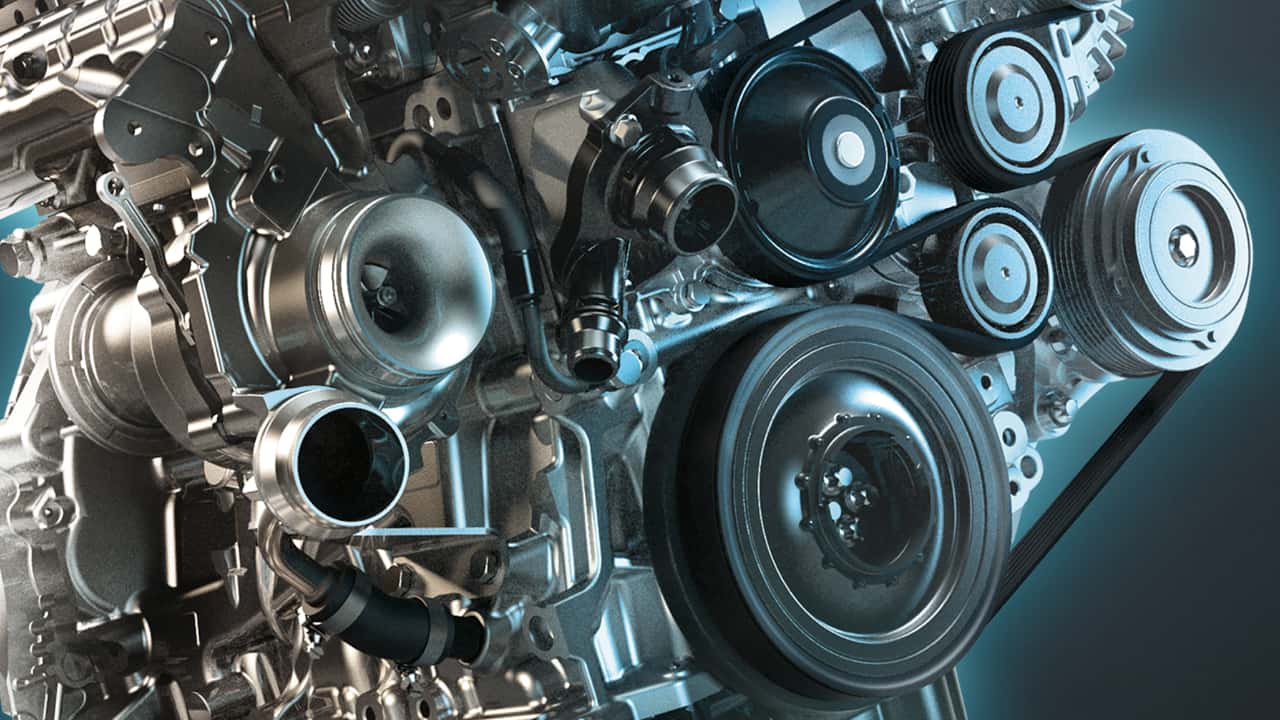

Understanding Belt V-Ribbed A Comprehensive Overview

In the world of automotive engineering and machinery, the significance of belts cannot be overstated. Among the various types of belts used in different applications, the V-ribbed belt stands out for its unique design and functional advantages. This article aims to explore the characteristics, advantages, and applications of the V-ribbed belt, shedding light on its critical role in various mechanical systems.

What is a V-Ribbed Belt?

A V-ribbed belt, also known as a serpentine belt, is a type of flexible mechanical component that transmits power in various machinery, especially in automotive engines. Unlike traditional V-belts, which have a triangular cross-section, V-ribbed belts feature multiple ribs along their length. These ribs engage with corresponding grooves on pulleys, providing enhanced grip and minimizing slippage.

Characteristics of V-Ribbed Belts

1. Design and Construction V-ribbed belts are composed of high-strength rubber that withstands wear and tear. The presence of ribs increases the surface area that contacts the pulley, resulting in improved traction.

2. Flexibility The design allows for a high degree of flexibility, enabling the belt to bend around pulleys and other components without losing efficiency.

3. Compactness Their compact design enables the use of smaller pulleys and a lighter weight overall, contributing to the efficiency of the engine or machinery.

4. Durability They are designed to endure extreme environmental conditions, including temperature fluctuations, exposure to oil, and chemicals, making them suitable for various applications.

Advantages of V-Ribbed Belts

belt v-ribbed

1. Efficiency V-ribbed belts provide efficient power transmission due to the high friction between the ribs and the pulleys. This efficiency translates to better performance and fuel economy in automotive applications.

2. Reduced Noise and Vibration The design of V-ribbed belts helps absorb vibration and reduce noise levels compared to traditional belts, contributing to a smoother and quieter operation.

3. Versatility V-ribbed belts can be used in a wide range of applications beyond automotive, including industrial machinery, HVAC systems, and more, making them a versatile choice for engineers.

4. Longer Lifespan Their robust construction often results in a longer lifespan than conventional belts, reducing the need for frequent replacements and lowering maintenance costs.

Applications

V-ribbed belts are widely used in vehicles, connecting the engine to various components such as the alternator, power steering pump, and air conditioning compressor. Their ability to drive multiple accessories with a single belt helps simplify the design of the engine compartment.

In industrial settings, V-ribbed belts are utilized in conveyor systems, textile manufacturing, and compressors, among other equipment. Their reliability and efficiency make them an integral part of modern machinery.

Conclusion

In summary, V-ribbed belts are a crucial component in mechanical systems, especially in the automotive and industrial sectors. Their unique design, flexibility, and durability offer numerous advantages, making them preferred for various applications. Understanding the importance of V-ribbed belts can lead to better maintenance practices and innovations in design, ultimately enhancing the performance and efficiency of the machinery they serve. As technology evolves, the role of belts, including V-ribbed varieties, will continue to be significant, underscoring the need for further research and development in this essential area of engineering.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025