- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

cze . 14, 2024 15:33 Back to list

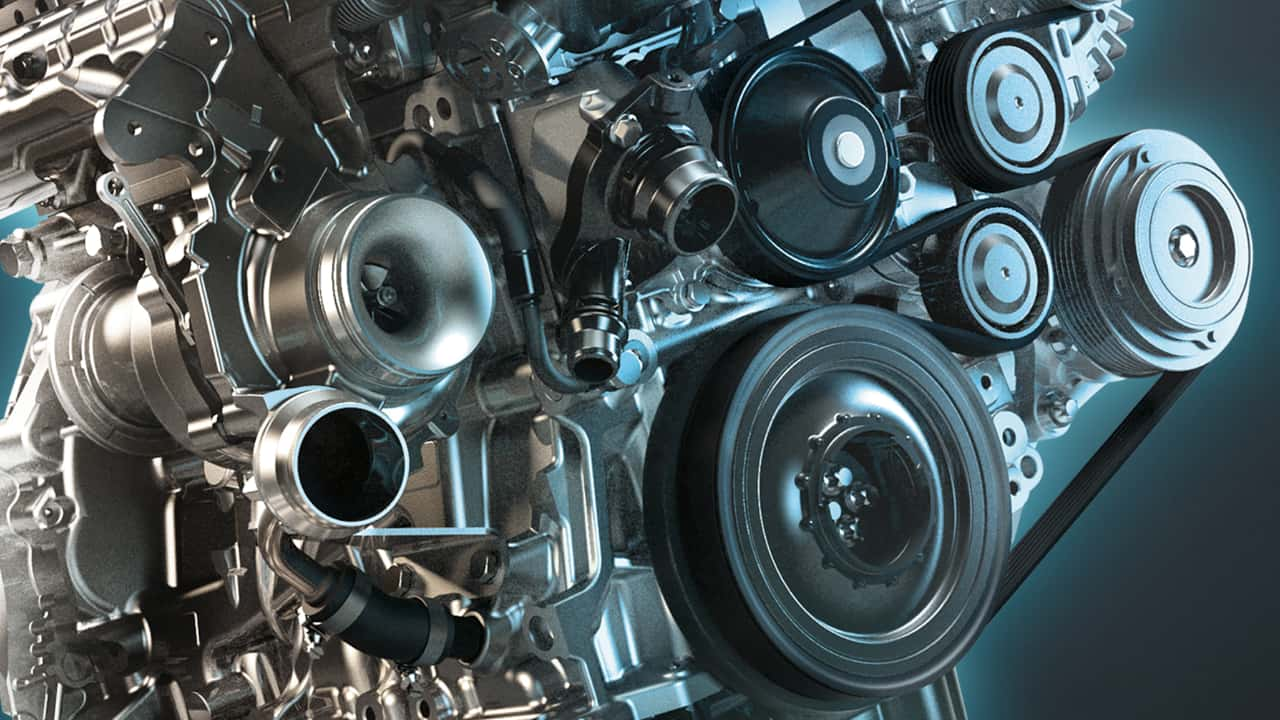

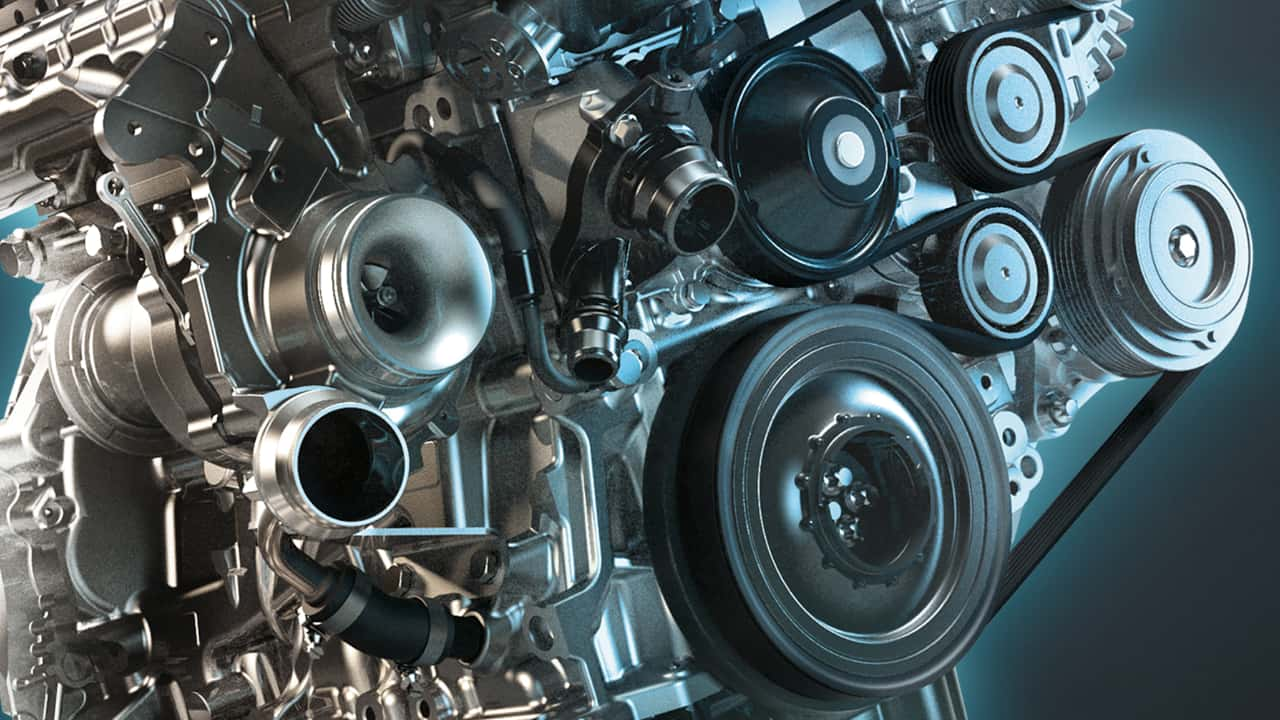

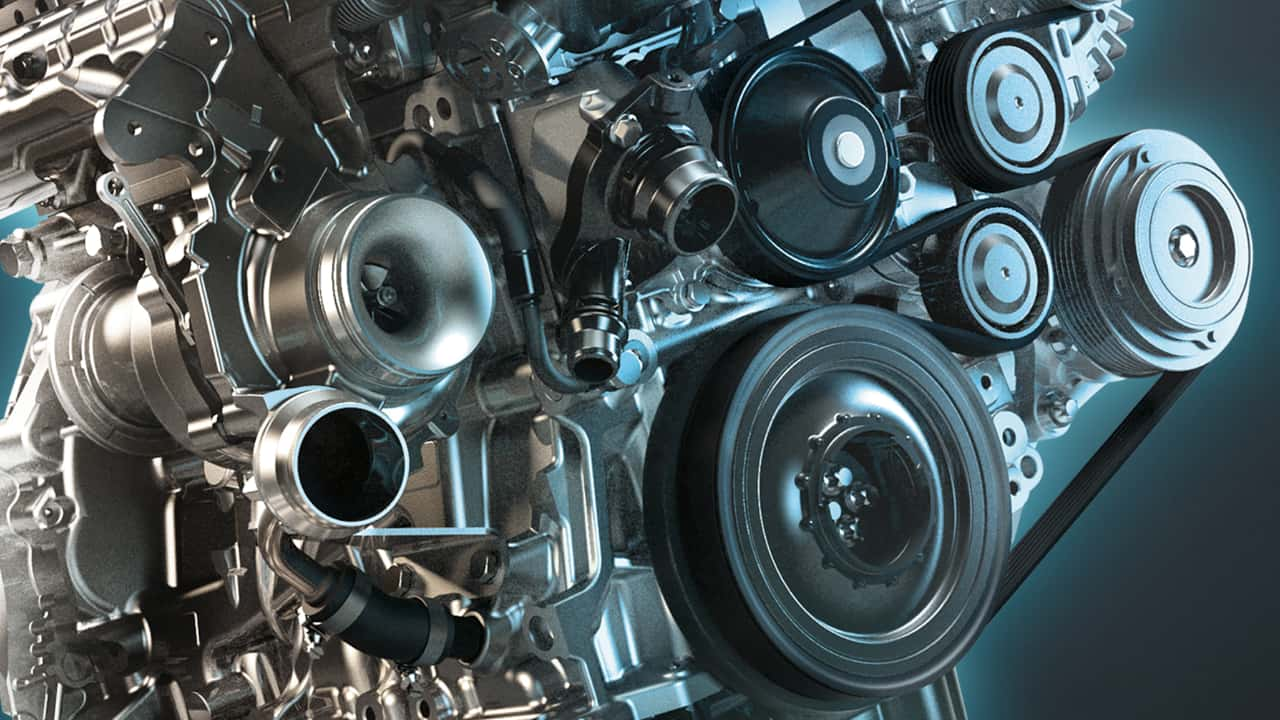

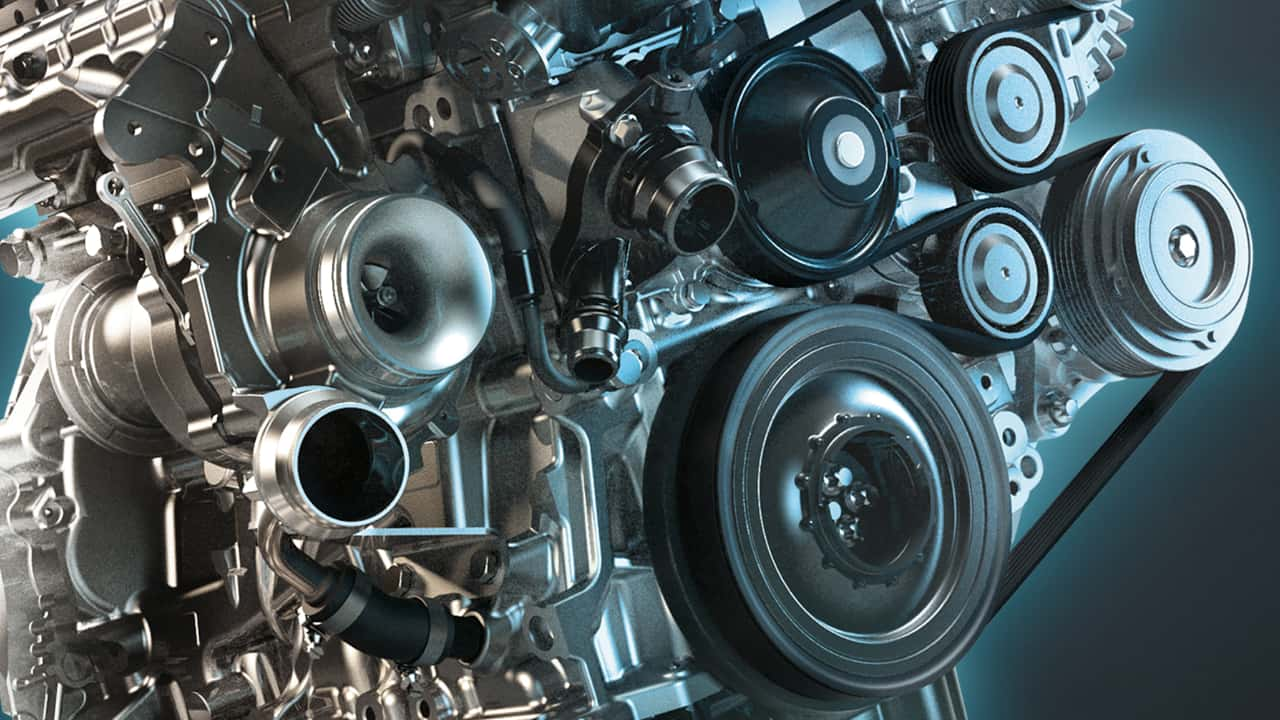

Tooth belt drives are commonly used in machinery.

The Intricacies of Tooth Belt Drives

Tooth belt drives, a type of power transmission system, have become increasingly prevalent in various industries due to their unique set of advantages over traditional chain drives and gear drives. This article delves into the intricacies of tooth belt drives, exploring their design, benefits, and applications.

At the heart of a tooth belt drive is the toothed belt, a durable composite consisting of a reinforced elastomer body with embedded tooth-shaped fibers or steel cables. This belt winds around a set of pulleys, known as sprockets, transferring motion and power between them without the need for external lubrication. The teeth on the belt precisely mesh with the sprocket's corresponding grooves, ensuring a positive drive that significantly reduces slippage and backlash.

One of the primary benefits of tooth belt drives is their quiet and smooth operation. Unlike chain drives, which can produce considerable noise and vibration, tooth belt drives operate nearly silently, making them ideal for machinery where noise needs to be minimized. Moreover, their precision engagement leads to accurate positioning, an essential factor in applications requiring high-positional accuracy such as robotics and CNC machines.

Another advantage of tooth belt drives is their energy efficiency. They typically have lower friction losses compared to other drive systems, leading to less energy consumption during operation. Additionally, tooth belt drives are often lighter than their counterparts, reducing the overall weight of machinery and potentially increasing its lifespan due to decreased load on the system.

Maintenance is another area where tooth belt drives shine. They require minimal upkeep compared to chain drives, which demand regular lubrication and tension adjustments They require minimal upkeep compared to chain drives, which demand regular lubrication and tension adjustments They require minimal upkeep compared to chain drives, which demand regular lubrication and tension adjustments They require minimal upkeep compared to chain drives, which demand regular lubrication and tension adjustments

They require minimal upkeep compared to chain drives, which demand regular lubrication and tension adjustments They require minimal upkeep compared to chain drives, which demand regular lubrication and tension adjustments tooth belt drive. However, tooth belts are not immune to wear and tear; they do stretch over time and may need periodic replacement or tensioning to maintain optimal performance.

In terms of applications, tooth belt drives are ubiquitous in the automotive industry, powering camshafts and accessories in engines. They are also prevalent in agricultural machinery, conveyor systems, and even in household appliances like washing machines and vacuum cleaners. The versatility of tooth belt drives allows them to scale from tiny mechanisms in electronics to massive industrial equipment with ease.

Despite their numerous benefits, tooth belt drives are not without drawbacks. They can be more costly initially than other drive systems, and the specialized tools required for installation and maintenance can add to the overhead costs. Furthermore, if a tooth belt fails, it can lead to complete system downtime until a replacement is sourced and installed.

In conclusion, tooth belt drives offer a compelling combination of efficiency, reliability, and versatility that make them an excellent choice for a wide range of mechanical applications. While they come with higher initial costs, their low maintenance requirements and superior performance often justify the investment in the long run. As technology continues to advance, it is likely that we will see further innovations in tooth belt drive design, enhancing their efficacy and expanding their potential uses in both existing and emerging industries.

tooth belt drive. However, tooth belts are not immune to wear and tear; they do stretch over time and may need periodic replacement or tensioning to maintain optimal performance.

In terms of applications, tooth belt drives are ubiquitous in the automotive industry, powering camshafts and accessories in engines. They are also prevalent in agricultural machinery, conveyor systems, and even in household appliances like washing machines and vacuum cleaners. The versatility of tooth belt drives allows them to scale from tiny mechanisms in electronics to massive industrial equipment with ease.

Despite their numerous benefits, tooth belt drives are not without drawbacks. They can be more costly initially than other drive systems, and the specialized tools required for installation and maintenance can add to the overhead costs. Furthermore, if a tooth belt fails, it can lead to complete system downtime until a replacement is sourced and installed.

In conclusion, tooth belt drives offer a compelling combination of efficiency, reliability, and versatility that make them an excellent choice for a wide range of mechanical applications. While they come with higher initial costs, their low maintenance requirements and superior performance often justify the investment in the long run. As technology continues to advance, it is likely that we will see further innovations in tooth belt drive design, enhancing their efficacy and expanding their potential uses in both existing and emerging industries.

They require minimal upkeep compared to chain drives, which demand regular lubrication and tension adjustments They require minimal upkeep compared to chain drives, which demand regular lubrication and tension adjustments

They require minimal upkeep compared to chain drives, which demand regular lubrication and tension adjustments They require minimal upkeep compared to chain drives, which demand regular lubrication and tension adjustments tooth belt drive. However, tooth belts are not immune to wear and tear; they do stretch over time and may need periodic replacement or tensioning to maintain optimal performance.

In terms of applications, tooth belt drives are ubiquitous in the automotive industry, powering camshafts and accessories in engines. They are also prevalent in agricultural machinery, conveyor systems, and even in household appliances like washing machines and vacuum cleaners. The versatility of tooth belt drives allows them to scale from tiny mechanisms in electronics to massive industrial equipment with ease.

Despite their numerous benefits, tooth belt drives are not without drawbacks. They can be more costly initially than other drive systems, and the specialized tools required for installation and maintenance can add to the overhead costs. Furthermore, if a tooth belt fails, it can lead to complete system downtime until a replacement is sourced and installed.

In conclusion, tooth belt drives offer a compelling combination of efficiency, reliability, and versatility that make them an excellent choice for a wide range of mechanical applications. While they come with higher initial costs, their low maintenance requirements and superior performance often justify the investment in the long run. As technology continues to advance, it is likely that we will see further innovations in tooth belt drive design, enhancing their efficacy and expanding their potential uses in both existing and emerging industries.

tooth belt drive. However, tooth belts are not immune to wear and tear; they do stretch over time and may need periodic replacement or tensioning to maintain optimal performance.

In terms of applications, tooth belt drives are ubiquitous in the automotive industry, powering camshafts and accessories in engines. They are also prevalent in agricultural machinery, conveyor systems, and even in household appliances like washing machines and vacuum cleaners. The versatility of tooth belt drives allows them to scale from tiny mechanisms in electronics to massive industrial equipment with ease.

Despite their numerous benefits, tooth belt drives are not without drawbacks. They can be more costly initially than other drive systems, and the specialized tools required for installation and maintenance can add to the overhead costs. Furthermore, if a tooth belt fails, it can lead to complete system downtime until a replacement is sourced and installed.

In conclusion, tooth belt drives offer a compelling combination of efficiency, reliability, and versatility that make them an excellent choice for a wide range of mechanical applications. While they come with higher initial costs, their low maintenance requirements and superior performance often justify the investment in the long run. As technology continues to advance, it is likely that we will see further innovations in tooth belt drive design, enhancing their efficacy and expanding their potential uses in both existing and emerging industries. Share:

Latest news

-

High-Quality Tensioner Belt Pulley - Durable & Efficient

NewsAug.03,2025

-

Premium Timing Belt Factory | AI-Optimized Solutions

NewsAug.02,2025

-

Premium Custom V Belts Enhanced with GPT-4 Turbo AI

NewsAug.01,2025

-

Car Serpentine Belt: AI-Optimized Performance with GPT-4-Turbo

NewsJul.31,2025

-

Heat Joining Drive Belt | High-Durability Fusion Solution

NewsJul.31,2025

-

Timing Belt Video Guide: Selection, Design & Quality Insights

NewsJul.30,2025