- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

sty . 14, 2025 12:03 Back to list

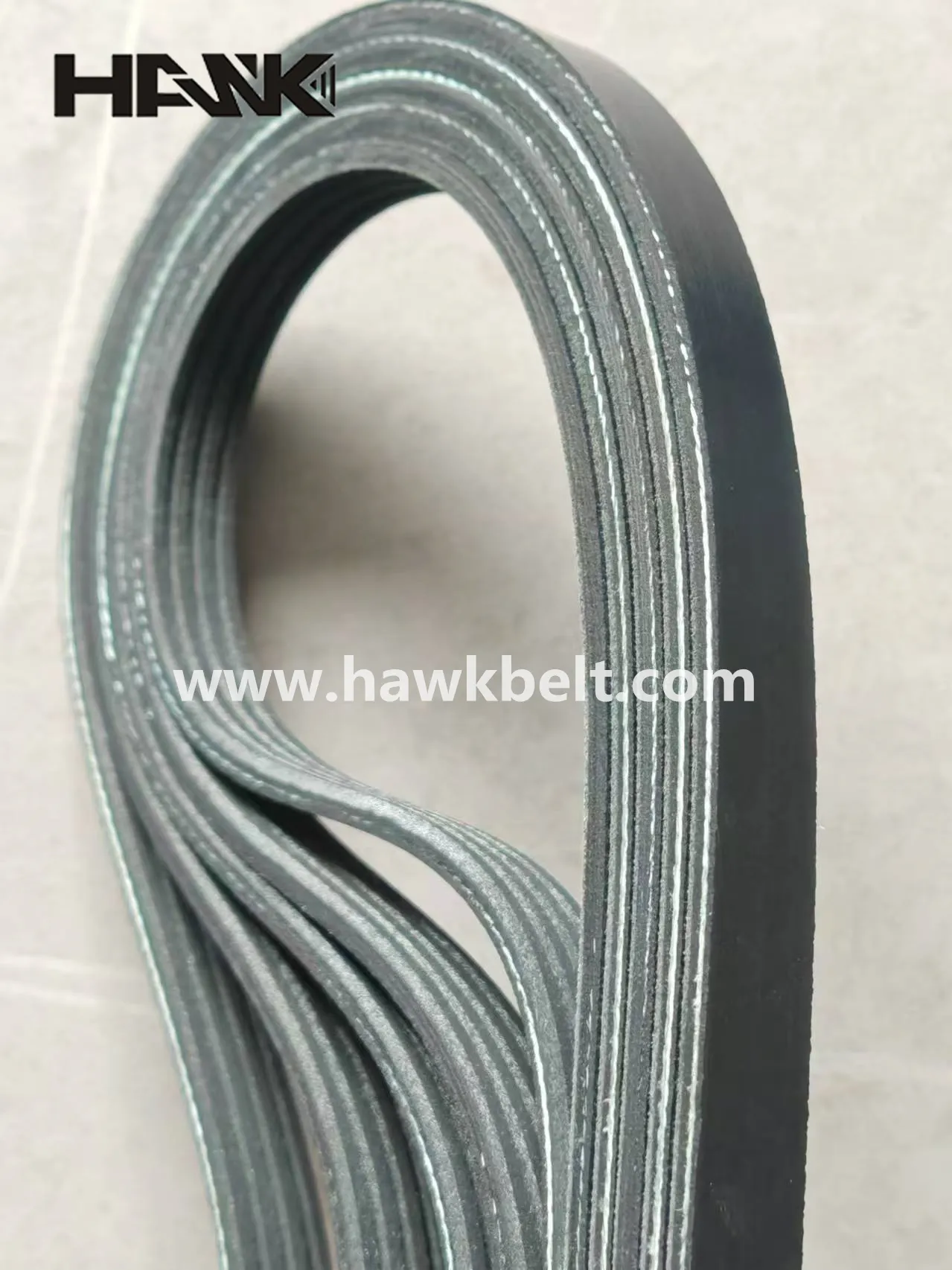

90916-T2022 PK Belt 7PK1870 For Toyota

Installing a serpentine belt is a crucial yet underappreciated task that plays a vital role in maintaining the health of your vehicle's engine. This essential component powers several vital peripherals, including the alternator, power steering pump, water pump, and air conditioning compressor. Approaching this task with a blend of technical knowledge and practical know-how not only extends the longevity of each supported component but also secures the overall performance of your vehicle.

Place the new serpentine belt over the pulleys following the specific order indicated in the routing diagram. Make sure the belt is seated properly within the grooves of each pulley. Once correctly aligned, reapply tension using the tensioner tool. A definitive 'snap' sound often signifies the belt has adequately engaged with the tensioner. Post-installation, it's crucial to conduct a visual and manual inspection. Confirm that the belt runs smoothly over each pulley, double-checking for proper alignment and tension. Start the engine and observe the belt in operation, looking for irregular movements or sounds, which may indicate misalignment or improper tensioning. Maintenance doesn't end with installation. Periodically inspect the serpentine belt for any indication of wear. Most experts recommend a comprehensive inspection every 30,000 miles, while replacement around every 60,000 to 100,000 miles is standard for most vehicles. Nonetheless, this can vary based on driving conditions and vehicle type, hence consulting the vehicle's manual or a trusted professional is always advisable. Precision and practice constitute the essence of expertise in serpentine belt installation. It's a seemingly straightforward process but requires meticulous attention and an understanding of your vehicle’s unique mechanics. By investing time and care into this process, you champion not only the integrity of your vehicle's engine components but also reinforce your role as a knowledgeable steward of your vehicle's health.

Place the new serpentine belt over the pulleys following the specific order indicated in the routing diagram. Make sure the belt is seated properly within the grooves of each pulley. Once correctly aligned, reapply tension using the tensioner tool. A definitive 'snap' sound often signifies the belt has adequately engaged with the tensioner. Post-installation, it's crucial to conduct a visual and manual inspection. Confirm that the belt runs smoothly over each pulley, double-checking for proper alignment and tension. Start the engine and observe the belt in operation, looking for irregular movements or sounds, which may indicate misalignment or improper tensioning. Maintenance doesn't end with installation. Periodically inspect the serpentine belt for any indication of wear. Most experts recommend a comprehensive inspection every 30,000 miles, while replacement around every 60,000 to 100,000 miles is standard for most vehicles. Nonetheless, this can vary based on driving conditions and vehicle type, hence consulting the vehicle's manual or a trusted professional is always advisable. Precision and practice constitute the essence of expertise in serpentine belt installation. It's a seemingly straightforward process but requires meticulous attention and an understanding of your vehicle’s unique mechanics. By investing time and care into this process, you champion not only the integrity of your vehicle's engine components but also reinforce your role as a knowledgeable steward of your vehicle's health.

Share:

Latest news

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025