- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

ਨਵੰ. . 10, 2024 08:02 Back to list

Understanding Power Transmission Belts for Efficient Mechanical Systems

Understanding Transmission Belts The Power Behind Mechanical Systems

Transmission belts play a crucial role in the functioning of various mechanical systems, serving as a vital link between different components. These belts are designed to efficiently transmit power from one part of a machine to another, enabling the transformation of energy into motion. This article delves into the types, functions, and applications of transmission belts, highlighting their importance in various industries.

What are Transmission Belts?

Transmission belts are flexible loops made of various materials, designed to transmit power between axles or moving parts in machinery. Commonly constructed from rubber, leather, or synthetic materials, these belts are engineered to withstand tension and friction while maintaining flexibility. The primary purpose of transmission belts is to transfer rotational motion and power from the engine or motor to other mechanical components, such as wheels, gears, or pumps.

Types of Transmission Belts

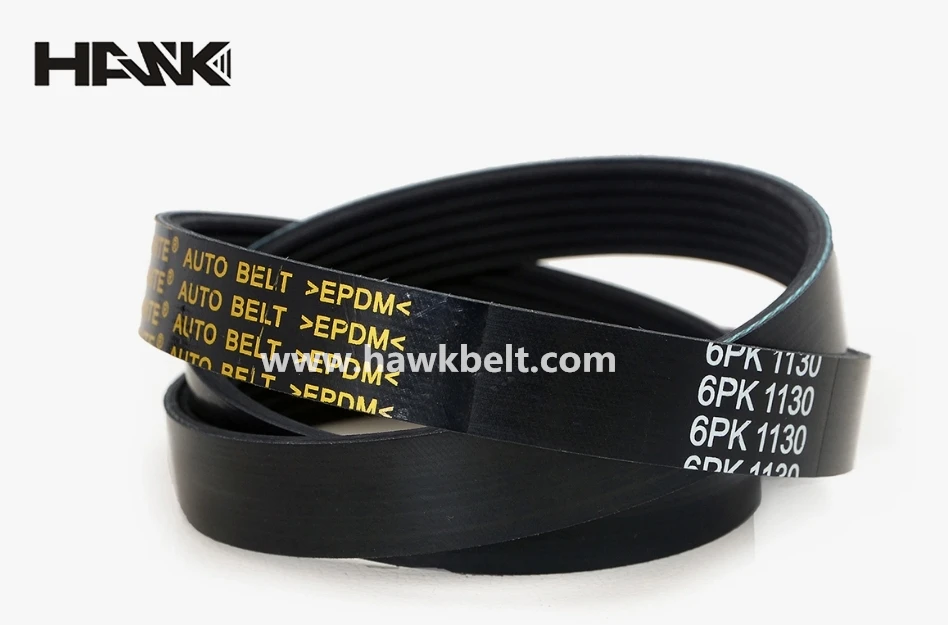

1. V-Belts These are among the most commonly used belts in mechanical systems. V-belts have a trapezoidal cross-section, allowing them to fit into pulleys and achieve a firm grip. They are ideal for transmitting power in a compact space and are widely used in agricultural machinery, HVAC systems, and automotive engines.

2. Flat Belts Unlike V-belts, flat belts have a rectangular cross-section. They are mostly used in applications with minimal tension and friction, such as conveyor systems and in older machinery. Flat belts provide a wide surface area for better grip, making them suitable for transmitting power over longer distances.

3. Timing Belts These belts are characterized by their toothed design, which ensures precise synchronization between the driving and driven components. Timing belts are crucial in applications where timing is essential, such as in engines and robotics. They prevent slippage, ensuring that the movement of parts is coordinated to avoid mechanical failures.

4. Round Belts Round belts are cylindrical and are often used in applications that require flexible and lightweight solutions. They are commonly found in small machinery, such as printers and sewing machines, where their ability to bend around pulleys is advantageous.

Benefits of Using Transmission Belts

1. Efficiency Transmission belts minimize energy loss during power transmission. Their design allows for smooth operation, reducing friction and improving overall efficiency.

2. Cost-Effectiveness Belts are generally less expensive to produce and replace compared to other power transmission systems like gears or chains. This affordability makes them a popular choice across various industries.

transmission belt\/power transmission belt

3. Flexibility Transmission belts can adapt to various overhung loads and misalignments, providing stability in mechanical systems. Their flexibility also allows them to navigate around different component layouts effectively.

4. Low Noise Operation Compared to other power transmission methods, belts generate less noise during operation, contributing to quieter working environments. This feature is particularly beneficial in consumer appliances and office equipment.

Applications of Transmission Belts

Transmission belts are ubiquitous across multiple sectors, including

- Automotive Industry V-belts and timing belts are integral to vehicles, driving various systems such as the water pump, alternator, and air conditioning compressor.

- Manufacturing In assembly lines, flat belts are used to power conveyor systems, enabling the movement of goods and materials seamlessly.

- Agriculture Agricultural machinery, such as tractors and combines, often relies on belts to operate critical components, ensuring efficient farming processes.

- HVAC Systems In heating, ventilation, and air conditioning units, belts are used to connect and operate fans and compressors effectively.

- Robotics Timing belts are essential in robotic applications where precise movement is crucial for tasks such as assembly and material handling.

Conclusion

Transmission belts are indispensable in modern mechanical systems, offering a reliable and efficient means of power transfer. With various types tailored to specific applications, they enhance operational efficiency across numerous industries. As technology progresses, the development of advanced materials and designs for transmission belts will likely continue, further improving their performance and expanding their applications. Understanding their functionality and importance can aid in appreciating the complexity and efficiency of the machines that power our daily lives.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025