- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

ਨਵੰ. . 19, 2024 23:28 Back to list

small flat belts

Understanding Small Flat Belts A Vital Component in Mechanical Engineering

In the realm of mechanical engineering, small flat belts play a crucial role in the effective transmission of power and motion between various components. Often overlooked, these simple yet efficient devices are fundamental in a myriad of applications across industries, from manufacturing to automotive.

What are Small Flat Belts?

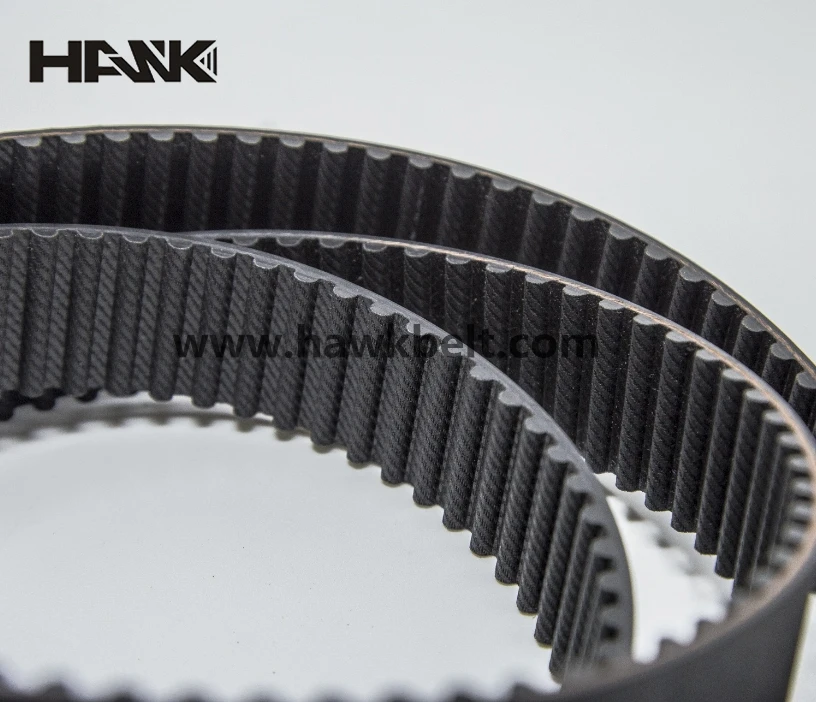

Small flat belts are flexible, linear components typically made from materials like rubber, leather, or synthetic polymers. These belts are characterized by their flat profile, distinguishing them from round belts or V-belts. The simplicity of their design allows them to operate smoothly over pulleys, transmitting power effectively without significant wear or slippage.

Applications of Small Flat Belts

One of the most common applications of small flat belts is in machinery where a seamless transfer of power is required. They are widely used in conveyor systems, where they facilitate the movement of products from one station to another. Additionally, they can be found in various textile machines, printers, and office equipment where precision and reliability are paramount.

In the automotive industry, small flat belts are integral to the operation of numerous mechanical systems. They are often used in alternators, water pumps, and air conditioning systems, ensuring that power is transmitted efficiently from the engine to these crucial components. Their ability to operate under various conditions without significant degradation makes them essential in vehicles.

Advantages of Using Small Flat Belts

One of the primary advantages of small flat belts is their simplicity. This simplicity translates into ease of maintenance and replacement, which is vital for many industries aiming to minimize downtime. Moreover, these belts exhibit excellent flexibility, allowing them to adapt to various pulley configurations while maintaining efficient power transfer.

Another significant benefit is their ability to handle high-speed operations with reduced noise. Unlike chain drives or gearing systems, flat belts operate quietly, making them ideal for applications where noise reduction is essential. This characteristic is particularly valued in environments like laboratories or office spaces.

small flat belts

Additionally, small flat belts can be manufactured in various widths and lengths, providing versatility for manufacturers. This adaptability ensures that they can be customized to fit specific machinery requirements, enhancing their utility in different sectors.

Challenges and Considerations

While small flat belts bring numerous advantages, they also pose certain challenges. One such challenge is the potential for slippage, particularly when the tension is not adequately maintained. In operations where consistent power transmission is crucial, careful alignment and tensioning of the belts are essential to avoid disruptions.

Moreover, the choice of materials is critical for the belt's performance and longevity. While rubber and synthetic materials offer durability, they can be susceptible to wear from environmental factors such as heat and moisture. Therefore, selecting a belt suited for a specific application, considering both operational conditions and expected lifespan, is vital.

Future Trends in Small Flat Belts

As technology advances, the development of new materials and manufacturing techniques may lead to improved designs for flat belts. Innovations in synthetic materials could enhance their resistance to environmental factors, resulting in longer-lasting and more efficient products. Additionally, the integration of smart technologies, such as sensors that monitor belt performance and wear, may become more prevalent, allowing for proactive maintenance strategies.

The growth of automation and robotics in industries also presents new opportunities for small flat belts. As more machinery becomes automated, the demand for reliable power transmission solutions like flat belts will likely increase.

Conclusion

In conclusion, small flat belts are more than mere components in mechanical systems; they are essential elements that enable efficient operation across various industries. Their simplicity, effectiveness, and adaptability make them a preferred choice for many applications. While challenges exist, ongoing advancements in materials and technology promise a bright future for these indispensable belts. As we continue to innovate and improve our machinery, the role of small flat belts will undoubtedly remain vital, supporting progress in mechanical engineering for years to come.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025