- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

ਸਤੰ. . 05, 2024 12:57 Back to list

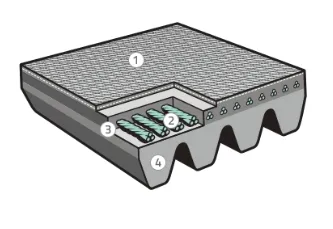

High-Quality Nylon Flat Belts for Various Applications

The Versatility of Nylon Flat Belts A Comprehensive Overview

Nylon flat belts are an integral component in numerous industrial applications, noted for their strength, flexibility, and durability. As synthetic materials have evolved, nylon has emerged as a favored option due to its unique properties that enhance functionality across a range of settings. This article explores the advantages, applications, and maintenance of nylon flat belts.

Advantages of Nylon Flat Belts

One of the primary benefits of nylon flat belts is their exceptional tensile strength. This allows them to handle heavy loads while maintaining their shape and integrity. Additionally, nylon's low friction coefficient makes these belts efficient in transferring power and reducing wear on the pulleys or drums they operate on.

Nylon is also resistant to many chemicals, oils, and abrasives, making it suitable for diverse environments, including factories and manufacturing plants. The material is lightweight, which facilitates easy handling and installation, further increasing its appeal. Furthermore, nylon flat belts can be produced in a variety of widths, lengths, and thicknesses, allowing for customization to fit specific machinery needs.

Applications of Nylon Flat Belts

nylon flat belt

Nylon flat belts find usage in various industries, including automotive, textiles, food processing, and logistics. In the automotive sector, they are employed in conveyor systems that transport parts during assembly. In textile manufacturing, nylon belts are crucial in weaving and fabric processing machines, where they contribute to efficient production lines.

In food processing, these belts play a vital role in conveying goods through different stages, from processing to packaging, where hygiene and durability are paramount. They are also commonly used in warehousing and logistics systems to facilitate the movement of goods, where their strength and reliability ensure efficient workflow.

Maintenance of Nylon Flat Belts

To maximize the lifespan and performance of nylon flat belts, regular maintenance is essential. Periodic inspections should be conducted to check for signs of wear, fraying, or misalignment. Keeping the belts clean from dust and oil can prevent slippage and enhance their operational efficiency. Additionally, ensuring proper tension can help avoid premature wear and potential system failures.

In conclusion, nylon flat belts are a versatile solution renowned for their resilience and efficiency across various industries. Their unique material properties not only enhance productivity but also contribute to the longevity of machinery. As technology advances, the role of nylon flat belts is likely to expand, making them indispensable in the modern industrial landscape. Whether in automotive manufacturing or food production, these belts are an essential component that underpins operational success.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025