- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

ਸਤੰ. . 07, 2024 01:14 Back to list

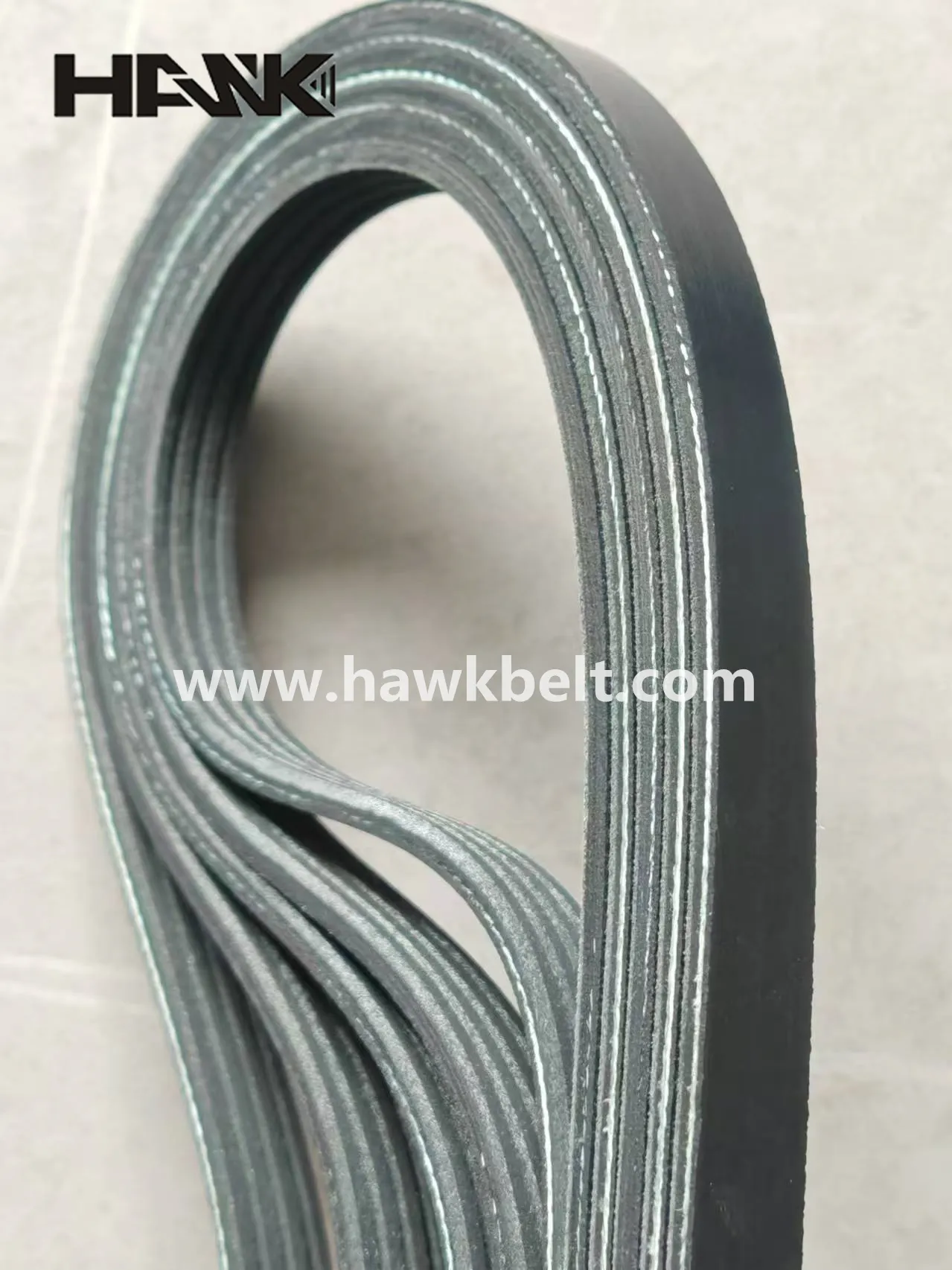

High-Quality Metric Variable Speed Belts for Optimal Performance

Understanding Metric Variable Speed Belts

In the world of mechanical engineering and industrial applications, the efficiency of power transmission systems is paramount. One innovative solution that has gained traction in recent years is the use of metric variable speed belts. These belts are designed to accommodate a wide range of operating conditions and provide optimal performance in various applications, making them a preferred choice in many sectors.

Metric variable speed belts are engineered to transmit power efficiently while allowing for adjustments in speed and torque. This flexibility is crucial in settings such as manufacturing, automotive, and packaging, where the speed of machinery must often be altered to suit different processes. By using variable speed belts, businesses can achieve better control over their operations, leading to enhanced productivity and reduced energy consumption.

One of the primary advantages of metric variable speed belts is their ability to minimize slippage. Unlike traditional belts, which may struggle under varying loads, variable speed belts are designed with materials and structures that ensure a tighter grip on the pulleys. This feature not only improves power transmission efficiency but also prolongs the lifespan of the belt, reducing maintenance costs and downtime associated with replacements.

metric variable speed belts

The dimensions of these belts are specified in metric units, making them compatible with European and international standards. This is an important consideration for manufacturers who operate on a global scale, as it ensures compatibility with machinery and systems designed for different regions. The availability of metric sizes also simplifies the procurement process, enabling companies to quickly find suitable belts for their applications.

Moreover, metric variable speed belts are often constructed from advanced materials that enhance their performance characteristics. For instance, rubber composite materials may be blended with synthetic fibers to increase durability and flexibility. This results in belts that can withstand higher temperatures and resist wear, making them ideal for demanding environments.

In addition to their mechanical benefits, metric variable speed belts also contribute to energy efficiency. By optimizing the speed of machines and reducing energy waste, these belts support sustainable manufacturing practices. Companies that adopt this technology can not only lower their operational costs but also bolster their commitment to environmental responsibility.

In conclusion, metric variable speed belts represent a significant advancement in the field of power transmission. Their ability to adapt to varying operational conditions, combined with their durability and efficiency, makes them an essential component for many industries. As technology continues to evolve, the role of these belts is likely to expand further, driving innovations in productivity and sustainability. For businesses looking to enhance their operations while maintaining high standards of performance, investing in metric variable speed belts is a strategic choice that can yield long-term benefits.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025