- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

ਜੂਨ . 30, 2024 14:00 Back to list

Efficient Transmission The Benefits and Selection of Narrow V-Belts

The Significance and Functionality of Narrow V-Belts in Modern Machinery

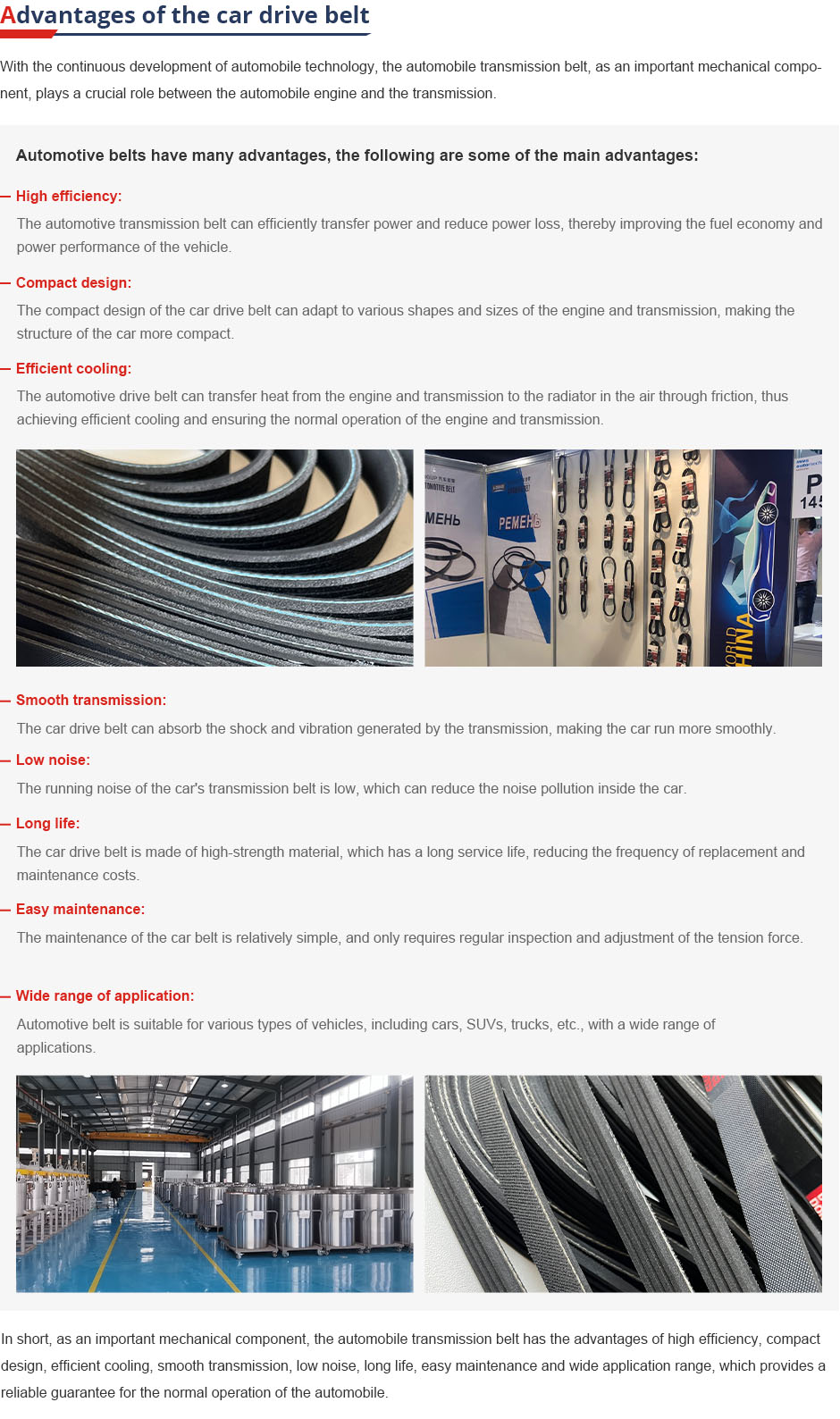

Narrow V-belts, an essential component in various mechanical systems, have been a cornerstone in the world of power transmission for decades. These specialized belts, characterized by their narrow width and trapezoidal cross-section, have evolved to become a highly efficient and reliable method of transmitting power from one pulley to another.

The design of narrow V-belts is rooted in the principle of friction-driven force transfer. Their unique shape allows them to nestle into the grooves of the pulleys, creating a strong grip that facilitates smooth and continuous rotation. This feature makes them ideal for applications where space is limited or when high power transmission is required with minimal belt tension.

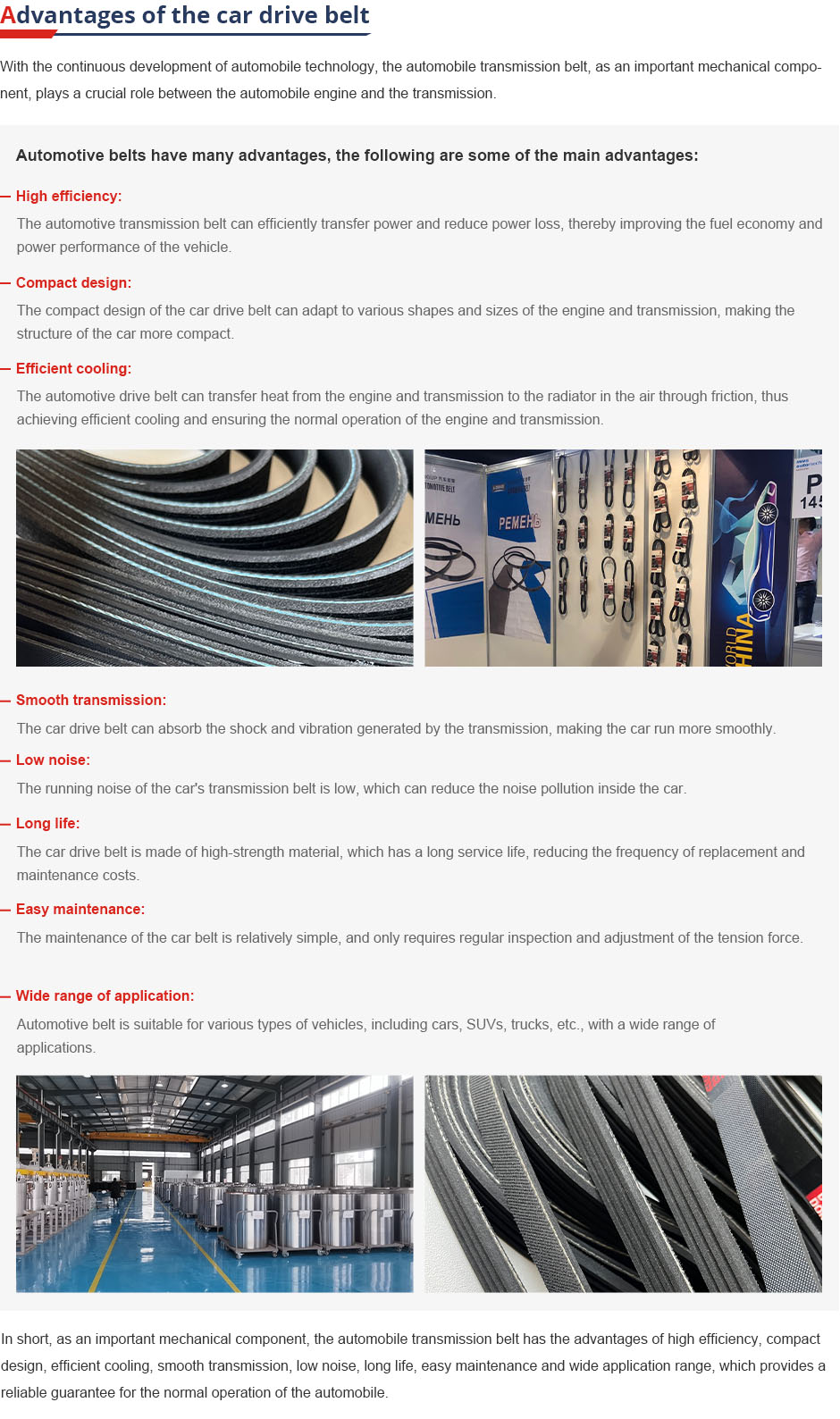

One of the key advantages of narrow V-belts is their efficiency. Due to the precise contact between the belt and the pulley, they can transmit power with minimal slippage, ensuring maximum energy transfer and reducing overall operational costs. Moreover, their compact design enables them to handle a wide range of speeds and loads, making them adaptable to diverse industrial settings.

Narrow V-belts also boast a long service life. Constructed from durable materials like rubber, polyester, or aramid cords, they can withstand harsh operating conditions and resist wear and tear. Their flexibility allows them to absorb shock loads, reducing stress on the machinery and preventing premature failure. Furthermore, their low maintenance requirements contribute to their popularity among engineers and technicians Furthermore, their low maintenance requirements contribute to their popularity among engineers and technicians Furthermore, their low maintenance requirements contribute to their popularity among engineers and technicians Furthermore, their low maintenance requirements contribute to their popularity among engineers and technicians

Furthermore, their low maintenance requirements contribute to their popularity among engineers and technicians Furthermore, their low maintenance requirements contribute to their popularity among engineers and technicians narrow v-belt.

In addition to their functional benefits, narrow V-belts contribute significantly to system compactness. They can be used in multi-groove pulleys, allowing multiple belts to operate simultaneously within a small space. This not only optimizes space utilization but also enhances load distribution, improving overall system performance.

Despite their simplicity, narrow V-belts play a critical role in numerous industries, from automotive and agriculture to manufacturing and HVAC systems. They power everything from small appliances to large industrial equipment, demonstrating their versatility and indispensability.

However, it's important to note that proper selection, installation, and maintenance of narrow V-belts are crucial for optimal performance. Factors such as belt length, pulley diameter, and tension must be considered to ensure efficient power transmission and prevent premature failure.

In conclusion, narrow V-belts, with their efficient power transmission, durability, and space-saving design, have become an integral part of modern machinery. As technology continues to evolve, so too will these belts, promising even greater efficiency and reliability in future applications. Despite their seemingly simple function, their impact on the functionality and productivity of various industries cannot be understated.

narrow v-belt.

In addition to their functional benefits, narrow V-belts contribute significantly to system compactness. They can be used in multi-groove pulleys, allowing multiple belts to operate simultaneously within a small space. This not only optimizes space utilization but also enhances load distribution, improving overall system performance.

Despite their simplicity, narrow V-belts play a critical role in numerous industries, from automotive and agriculture to manufacturing and HVAC systems. They power everything from small appliances to large industrial equipment, demonstrating their versatility and indispensability.

However, it's important to note that proper selection, installation, and maintenance of narrow V-belts are crucial for optimal performance. Factors such as belt length, pulley diameter, and tension must be considered to ensure efficient power transmission and prevent premature failure.

In conclusion, narrow V-belts, with their efficient power transmission, durability, and space-saving design, have become an integral part of modern machinery. As technology continues to evolve, so too will these belts, promising even greater efficiency and reliability in future applications. Despite their seemingly simple function, their impact on the functionality and productivity of various industries cannot be understated.

Furthermore, their low maintenance requirements contribute to their popularity among engineers and technicians Furthermore, their low maintenance requirements contribute to their popularity among engineers and technicians

Furthermore, their low maintenance requirements contribute to their popularity among engineers and technicians Furthermore, their low maintenance requirements contribute to their popularity among engineers and technicians narrow v-belt.

In addition to their functional benefits, narrow V-belts contribute significantly to system compactness. They can be used in multi-groove pulleys, allowing multiple belts to operate simultaneously within a small space. This not only optimizes space utilization but also enhances load distribution, improving overall system performance.

Despite their simplicity, narrow V-belts play a critical role in numerous industries, from automotive and agriculture to manufacturing and HVAC systems. They power everything from small appliances to large industrial equipment, demonstrating their versatility and indispensability.

However, it's important to note that proper selection, installation, and maintenance of narrow V-belts are crucial for optimal performance. Factors such as belt length, pulley diameter, and tension must be considered to ensure efficient power transmission and prevent premature failure.

In conclusion, narrow V-belts, with their efficient power transmission, durability, and space-saving design, have become an integral part of modern machinery. As technology continues to evolve, so too will these belts, promising even greater efficiency and reliability in future applications. Despite their seemingly simple function, their impact on the functionality and productivity of various industries cannot be understated.

narrow v-belt.

In addition to their functional benefits, narrow V-belts contribute significantly to system compactness. They can be used in multi-groove pulleys, allowing multiple belts to operate simultaneously within a small space. This not only optimizes space utilization but also enhances load distribution, improving overall system performance.

Despite their simplicity, narrow V-belts play a critical role in numerous industries, from automotive and agriculture to manufacturing and HVAC systems. They power everything from small appliances to large industrial equipment, demonstrating their versatility and indispensability.

However, it's important to note that proper selection, installation, and maintenance of narrow V-belts are crucial for optimal performance. Factors such as belt length, pulley diameter, and tension must be considered to ensure efficient power transmission and prevent premature failure.

In conclusion, narrow V-belts, with their efficient power transmission, durability, and space-saving design, have become an integral part of modern machinery. As technology continues to evolve, so too will these belts, promising even greater efficiency and reliability in future applications. Despite their seemingly simple function, their impact on the functionality and productivity of various industries cannot be understated. Share:

Latest news

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025