- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Dec . 16, 2024 00:43 Back to list

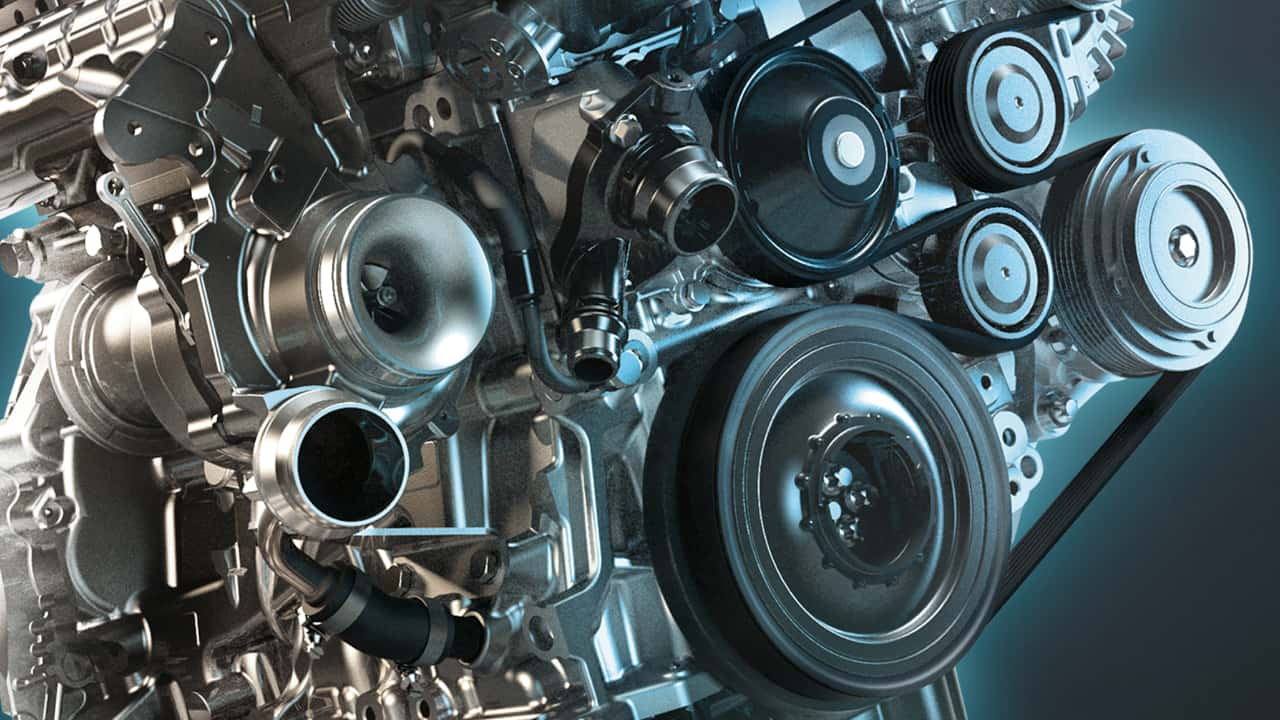

sprocket and toothed belt

Understanding Sprockets and Toothed Belts An Essential Link in Mechanical Systems

In the realm of mechanical engineering and automation, the significance of various components that facilitate power transmission and motion cannot be overstated. Among these components, sprockets and toothed belts play a critical role. Their dependable functionality is pivotal in numerous applications, from simple machines to complex industrial equipment. This article explores the fundamental principles behind sprockets and toothed belts, their applications, advantages, and maintenance considerations.

What are Sprockets?

Sprockets are mechanical components consisting of a wheel with teeth that interlock with a chain or in some contexts, a toothed belt. These teeth engage with the links of a chain or the grooves of a belt, allowing for the transfer of torque and rotational motion from one shaft to another. Sprockets come in various shapes and sizes, tailored to specific requirements, including the number of teeth, pitch diameter, and material composition.

Understanding Toothed Belts

Similar to chains, toothed belts are crucial in the transmission of power and motion. Unlike traditional flat belts, toothed belts feature a series of evenly spaced teeth along their length that align with the sprocket's teeth. This design minimizes slippage and allows for enhanced grip, making them highly efficient in transferring power. Toothed belts are typically made of rubber or polyurethane, often reinforced with materials like fiberglass or steel to enhance strength and durability.

How They Work Together

The synergy between sprockets and toothed belts creates a highly efficient power transmission system. When a motor drives a sprocket, the rotation is directly transferred to the toothed belt. As the belt moves, its teeth engage with the sprocket's teeth, resulting in motion that is both precise and consistent. This setup is especially beneficial in applications requiring synchronization and accuracy, such as in robotics, conveyor systems, and automotive timing engines.

Applications of Sprockets and Toothed Belts

The versatility of sprockets and toothed belts allows for a wide range of applications.

1. Automotive Industry In vehicles, toothed belts are often used in camshaft and timing belt systems to synchronize engine components, ensuring that valves and pistons move in perfect harmony. This critical function enhances engine performance and efficiency.

2. Industrial Machinery Sprocket and toothed belt systems are prevalent in manufacturing plants. They are used in conveyor systems to transport materials and products throughout the production line, providing reliability and speed.

sprocket and toothed belt

3. Bicycles Many modern bicycles utilize toothed belts instead of traditional chains for power transmission. This innovation results in a quieter, cleaner ride with reduced maintenance needs.

4. 3D Printers In the realm of additive manufacturing, precision is paramount. Sprockets and toothed belts are essential in providing the exact movements required for layer deposition, contributing significantly to print quality and accuracy.

Advantages of Sprockets and Toothed Belts

The preference for sprockets and toothed belts over traditional belt systems lies in several advantages

1. Efficiency The precise engagement of teeth reduces energy loss, resulting in higher efficiency levels compared to non-toothed belts or chains.

2. Reduced Maintenance Toothed belts do not require lubrication like chains, leading to less frequent maintenance and longer operational life.

3. Noise Reduction Toothed belts operate more quietly than chains, making them ideal for applications where noise reduction is a priority.

4. Compact Design The design of sprockets and toothed belts allows for a more compact setup compared to traditional power transmission systems, saving space in machinery design.

Maintenance Considerations

Despite their advantages, proper maintenance of sprockets and toothed belts is crucial for ensuring longevity and performance. Regular inspections for signs of wear, proper tension adjustment, and alignment are vital practices. Additionally, avoiding exposure to excessive heat, chemicals, or contaminants will help maintain their integrity and functionality.

Conclusion

Sprockets and toothed belts are indispensable elements in the machinery and automation landscape. Their ability to provide efficient, reliable, and precise motion makes them a preferred choice in various industries. Understanding the mechanics and applications of these components can help engineers and technicians design better systems and ensure optimal performance in their respective fields. As technology advances, the evolution of sprockets and toothed belts will undoubtedly continue, further enhancing their capabilities and applications in our increasingly automated world.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025