- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Nov . 14, 2024 04:26 Back to list

mechanical drives & belting

Mechanical Drives and Belting An Overview

Mechanical drives and belting play a crucial role in the transmission of power in various industrial machines and equipment. As integral components of numerous mechanical systems, they ensure that energy is transferred efficiently and reliably from one part of a machine to another. This article provides an overview of mechanical drives and belting, highlighting their types, applications, and importance in modern engineering.

Mechanical Drives and Belting An Overview

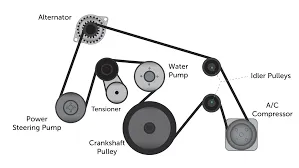

Belting, a common method of indirect drive, involves the use of flexible straps or loops to transmit power between pulleys. The most widely used materials for belts include rubber, polyurethane, and leather, each offering distinct characteristics suited to different applications. There are various types of belts, including flat belts, V-belts, and timing belts, each designed to optimize performance under specific conditions. For example, V-belts provide excellent grip and are commonly used in automotive engines, while timing belts ensure precise synchronization of rotating components.

mechanical drives & belting

The selection of the appropriate belting system depends on several factors, including load capacity, speed, temperature range, and environmental conditions. Proper alignment and tensioning of belts are crucial to avoid slippage and wear, which can lead to inefficiencies and increased maintenance costs. Periodic inspection and replacement of worn belts are essential practices in maintaining optimal operational efficiency.

Mechanical drives and belting find applications across a diverse range of industries. In manufacturing, they are used in conveyor systems, enabling the efficient movement of materials through production lines. In the automotive sector, belts drive essential components such as alternators and water pumps, ensuring that the engine operates smoothly. Furthermore, in agriculture, mechanical drives and belting are vital in operating equipment like tractors, harvesters, and irrigation systems.

In addition to efficiency and reliability, mechanical drives and belting contribute to safety in industrial operations. By minimizing vibration and noise, they help create a safer working environment and reduce the risk of mechanical failure. Moreover, advancements in technology have led to the development of more robust and durable belting materials, resulting in longer service life and reduced downtime.

In conclusion, mechanical drives and belting are fundamental elements of today's industrial landscape. Their ability to transmit power efficiently and reliably makes them indispensable in various applications. As industries continue to evolve, the demand for innovative and efficient drive systems will increase, driving further advancements in mechanical engineering. Understanding the principles and applications of mechanical drives and belting is crucial for engineers and operators in ensuring the success and longevity of their machinery.

-

Durable Diesel Engine Belt with GPT-4-Turbo AI Tech | Precision Fit

NewsAug.04,2025

-

High-Quality Tensioner Belt Pulley - Durable & Efficient

NewsAug.03,2025

-

Premium Timing Belt Factory | AI-Optimized Solutions

NewsAug.02,2025

-

Premium Custom V Belts Enhanced with GPT-4 Turbo AI

NewsAug.01,2025

-

Car Serpentine Belt: AI-Optimized Performance with GPT-4-Turbo

NewsJul.31,2025

-

Heat Joining Drive Belt | High-Durability Fusion Solution

NewsJul.31,2025