- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Nov . 11, 2024 04:12 Back to list

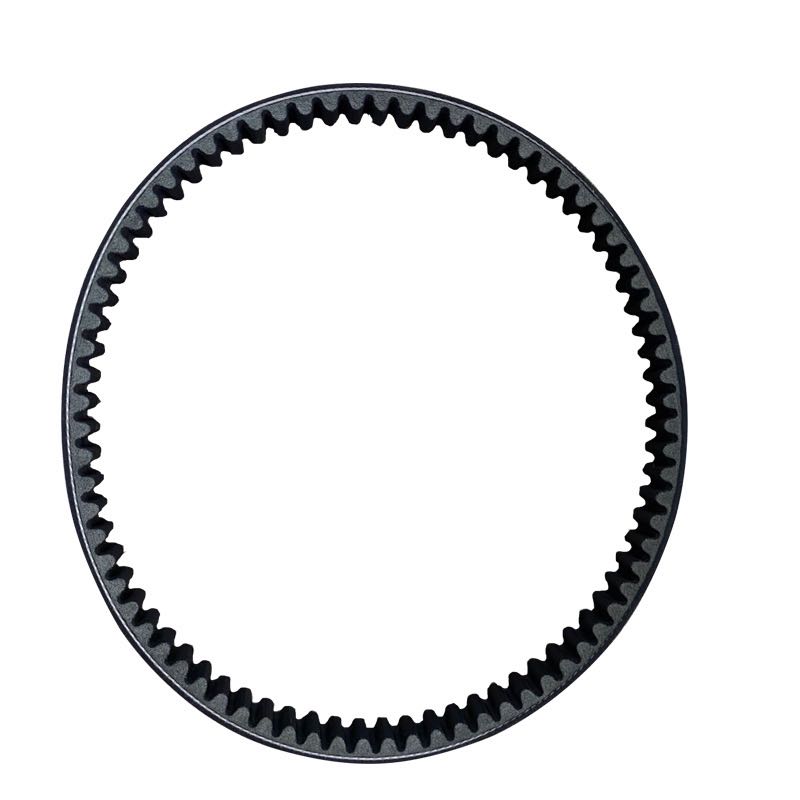

V-Belt Production and Suppliers Overview for Various Industries and Applications

The V-Belt Manufacturing Industry An Overview

The V-belt is an essential component in numerous mechanical systems, serving as a crucial link between motors and machinery to transfer power efficiently. The design and functionality of V-belts have evolved significantly since their inception, making them a vital part of a variety of applications, from industrial machinery to household appliances. In this article, we will explore the V-belt manufacturing industry, focusing on the key players, production processes, and future trends.

Understanding V-Belts

V-belts are characterized by their trapezoidal cross-section, which is designed to fit into matching grooves on pulleys. This shape allows for greater friction and better power transmission compared to flat belts. Commonly made from rubber, they can also include fabric, steel cords, and other materials to enhance durability and performance. V-belts are widely used in automobiles, HVAC systems, agricultural equipment, and many other machines that require reliable power transmission.

V-Belt Manufacturers Key Players in the Industry

The V-belt manufacturing industry comprises several prominent companies known for their innovation and quality. These manufacturers range from large international corporations to specialized local producers. Industry giants like Gates Corporation, Continental AG, and Dayco are known for their extensive product lines and global reach. They invest heavily in research and development to introduce new materials and designs that improve efficiency and lifespan.

In addition to these major players, smaller manufacturers also contribute to the market by offering niche products or specialized V-belts tailored for specific applications. This diversity allows customers to find solutions that meet their unique operational requirements.

Production Processes

The manufacturing of V-belts involves several stages, each crucial to ensuring the final product’s quality and performance. The process typically begins with selecting raw materials, which may include natural rubber, synthetic rubber, and reinforcing materials. Following this, the raw materials are mixed to create compounds that possess the desirable characteristics for flexibility, strength, and durability.

v belts manufactures

Once the compounds are prepared, they are processed using various techniques such as extrusion, where the rubber is shaped into the desired profile. This is followed by curing, a crucial step that involves heating the rubber to achieve its final mechanical properties. The cured belts are then subjected to quality control testing, ensuring they meet the industry standards for performance and reliability.

Modern V-belt manufacturers increasingly incorporate automation and advanced technologies into their production processes. Computer-aided design (CAD) and computer numerical control (CNC) machining facilitate precision in manufacturing, resulting in higher-quality products with tighter tolerances.

Market Trends and Future Outlook

The V-belt industry faces several trends that could shape its future. One notable trend is the growing demand for energy-efficient power transmission solutions. As industries shift towards sustainability, there is an increasing need for V-belts that can operate more efficiently, reducing energy consumption and greenhouse gas emissions.

Additionally, technological advancements in materials science are leading to the development of new types of V-belts. Manufacturers are exploring the use of advanced composites that offer improved performance characteristics, such as increased heat resistance, chemical resistance, and longer service life.

Another key trend is the globalization of the supply chain. Manufacturers are expanding their operations to emerging markets, where demand for V-belts is steadily increasing due to industrial growth. This expansion presents both opportunities and challenges, as companies must navigate different regulatory environments and market dynamics.

Conclusion

The V-belt manufacturing industry is a dynamic sector that plays a critical role in the global economy. With a focus on innovation, efficiency, and sustainability, manufacturers are poised to meet the evolving needs of various industries. As technology continues to advance and markets grow, the future of V-belt manufacturing looks promising, aligning with the trends of modernization and environmental responsibility. By understanding the key players and production processes, industry stakeholders can better navigate this ever-changing landscape, ensuring continued growth and success in the years to come.

-

Upgrade Power Steering Pump Belt for Smooth, Quiet Operation

NewsAug.27,2025

-

Precision Timing Belt & Chain: Engine Performance & Durability

NewsAug.26,2025

-

Precision Lathe Drive Belts: Durable & Reliable Performance

NewsAug.25,2025

-

84.5 Serpentine Belt: Durable & Precision Fit for Your Engine

NewsAug.24,2025

-

Premium Ribbed Drive Belts for Quiet Power Transmission

NewsAug.23,2025

-

High-Performance Vehicle Timing Belt for Engine Precision

NewsAug.22,2025