- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Oct . 10, 2024 16:36 Back to list

v belt for compressor

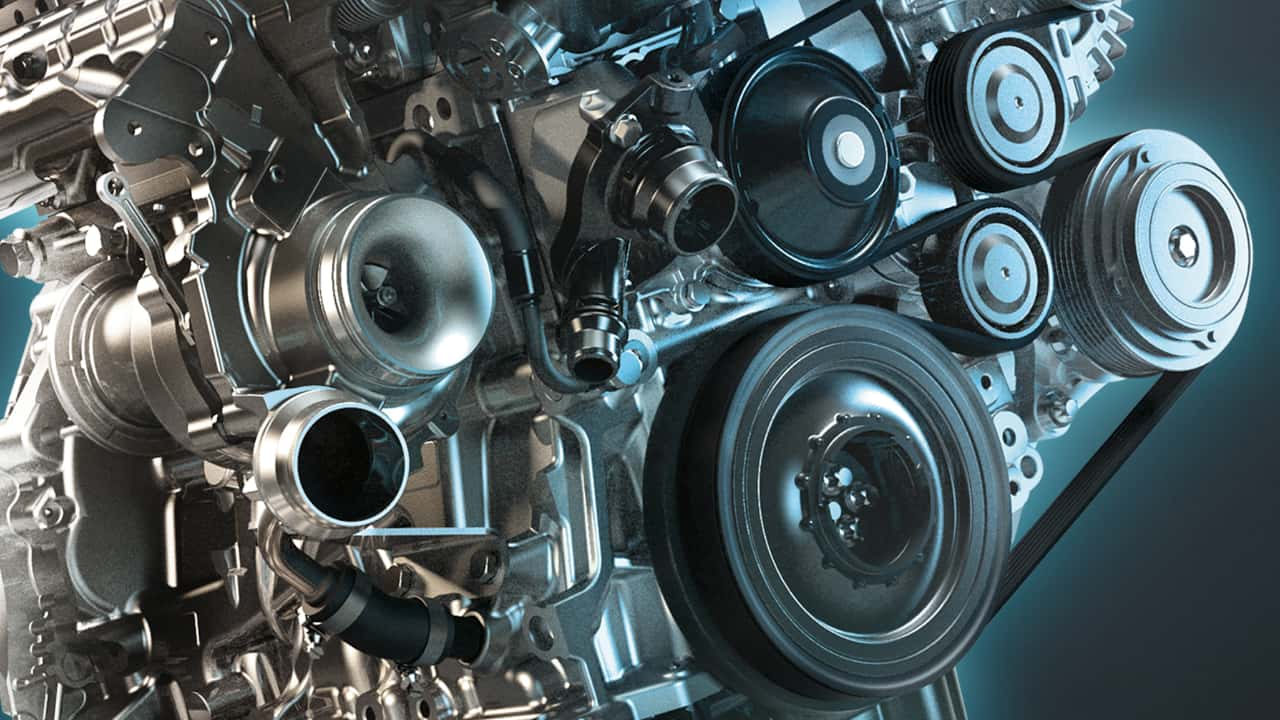

Understanding V-Belts for Compressors Essential Components for Optimal Performance

When it comes to the effective operation of various machines and industrial equipment, the V-belt is a critical component that often goes unnoticed. Particularly in compressors, V-belts play a crucial role in transmitting power, ensuring that these machines operate efficiently and reliably. This article delves into the importance of V-belts in compressors, the types available, and the factors to consider when selecting and maintaining them.

What is a V-Belt?

A V-belt is a type of flexible power transmission belt with a trapezoidal cross-section that fits into a groove of a matching pulley. This design allows the belt to grip the pulley effectively, minimizing slippage and maximizing power transfer. V-belts are widely used across various applications, but they are particularly vital in compressor systems where reliability and efficiency are paramount.

The Role of V-Belts in Compressors

Compressors, which are essential for compressing gases, depend on V-belts to connect the motor to the compressor unit. When the motor runs, it turns the pulley, which, in turn, drives the V-belt. This mechanism converts the motor's rotational motion into the linear motion needed to perform the compression cycle. The efficiency of this power transference directly affects the compressor’s performance, energy consumption, and overall lifespan.

Types of V-Belts

There are several types of V-belts available, each designed for specific applications and performance requirements. Some of the most common types include

1. Standard V-Belts These are used in various applications and are suitable for many industrial machines, including compressors. They are generally made of a rubber or synthetic material and can handle moderate tension and load.

2. Narrow V-Belts These belts have a smaller profile than standard V-belts, which allows them to handle higher speeds and tighter pulleys. However, they may not be able to handle as much load as their wider counterparts.

3. Cogged V-Belts Featuring notches or cogs, these belts provide improved flexibility and grip. Cogged belts are particularly effective in applications requiring high speed and power transmission. They are less prone to slippage, which enhances their performance in compressors.

4. Poly-V Belts Also known as multi-ribbed belts, these have multiple grooves and offer a larger contact surface with the pulley. This design allows for efficient power transfer and is ideal for high-performance applications.

Choosing the Right V-Belt for Your Compressor

v belt for compressor

Selecting the right V-belt for your compressor is crucial for ensuring optimal performance. Consider the following factors

- Load Requirements Assess the load specifications of your compressor. Heavier loads may necessitate the use of wider or cogged belts to ensure adequate power transmission without slippage.

- Speed Ratings Different V-belts are designed to operate at various speed ratings

. Choose a belt that matches or exceeds the speed of your compressor’s motor to avoid premature wear.- Environmental Conditions If your compressor operates in harsh environments, consider belts made from materials resistant to heat, oil, and chemicals. This will enhance durability and performance over time.

- Compatibility Ensure the V-belt is compatible with the pulleys on your compressor. Correct sizing is essential to prevent slippage and ensure efficient operation.

Maintenance and Care

To prolong the life of your V-belt and maintain optimal compressor performance, regular maintenance is essential. This can include

- Regular Inspections Check for signs of wear, cracking, or fraying. Early detection of wear can prevent costly breakdowns.

- Tension Checks Ensure that the belt is properly tensioned. Both over-tensioning and under-tensioning can lead to premature wear and failure.

- Alignment Ensure that pulleys are correctly aligned. Misalignment can cause uneven wear and reduce efficiency.

- Cleaning Keep the belt and pulley surfaces clean to avoid contamination that could lead to slip or wear.

Conclusion

V-belts are indispensable components in compressor systems, playing a critical role in power transmission and overall efficiency. Understanding the different types of V-belts, selecting the right one for your specific compressor requirements, and maintaining them properly can significantly enhance performance and extend the lifespan of your equipment. By prioritizing the health of your V-belt, you ensure the reliability and efficiency of your compressor, ultimately leading to improved productivity and cost savings in your operations.

-

Upgrade Power Steering Pump Belt for Smooth, Quiet Operation

NewsAug.27,2025

-

Precision Timing Belt & Chain: Engine Performance & Durability

NewsAug.26,2025

-

Precision Lathe Drive Belts: Durable & Reliable Performance

NewsAug.25,2025

-

84.5 Serpentine Belt: Durable & Precision Fit for Your Engine

NewsAug.24,2025

-

Premium Ribbed Drive Belts for Quiet Power Transmission

NewsAug.23,2025

-

High-Performance Vehicle Timing Belt for Engine Precision

NewsAug.22,2025