- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Nov . 12, 2024 08:16 Back to list

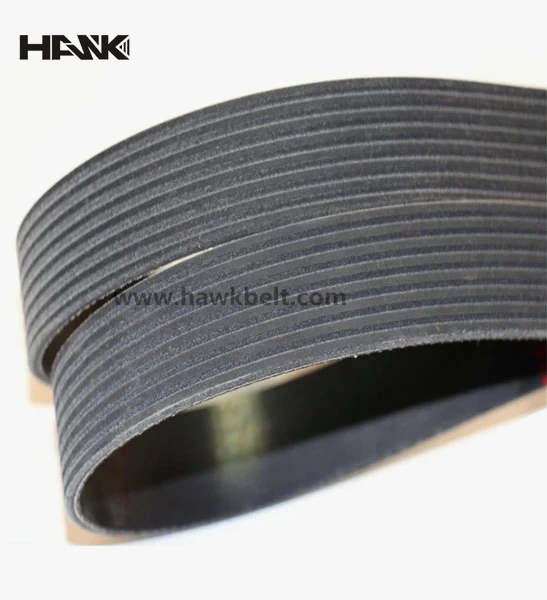

v belt double teeth

Understanding V-Belts and Double Teeth Design

In the world of mechanical engineering, efficiency and reliability are paramount. One of the critical components that contribute to these values is the V-belt. V-belts are widely used in various mechanical systems, including automotive engines, industrial machinery, and countless applications where power transmission is required. Among the various types of V-belts, those with double teeth designs have gained popularity for their enhanced performance characteristics. This article delves into the significance of V-belts, particularly focusing on double teeth designs, and their operational advantages.

What is a V-Belt?

A V-belt is a type of belt used to transmit power between shafts. Its trapezoidal cross-section is designed to fit into a corresponding groove in pulleys, allowing for effective grip and reduced slippage. V-belts offer several advantages over traditional flat belts, including higher power transmission capabilities, improved traction, and the ability to run at higher speeds. However, as technology has progressed, the design and materials used in V-belts have evolved, leading to innovations like the double teeth V-belt.

The Role of Double Teeth Design

The double teeth design refers to the construction of the belt where the contact surface with the pulley has two sets of teeth or grooves. This design enhances several operational aspects of the V-belt

1. Increased Power Transmission The dual contact points provided by the double teeth allow for a more substantial contact area with the pulley. This characteristic increases the amount of power that can be transmitted without slippage, making it ideal for heavy-duty applications where high torque is required.

2. Improved Flexibility The double teeth construction allows for greater flexibility and bendability of the belt. This is particularly important in applications where the belt must navigate around pulleys with varying diameters or complex configurations. The increased flexibility reduces the risk of belt fatigue and breakage.

3. Enhanced Load Distribution Load distribution is critical in maintaining the longevity of any power transmission system. The double teeth design provides a more even load distribution across the belt, minimizing localized wear. This longevity translates into lower maintenance costs and downtime for equipment relying on these belts.

4. Reduced Noise and Vibration Double teeth V-belts tend to operate more quietly compared to traditional belts. The design minimizes vibrations that can occur during power transmission, contributing to overall system stability and comfort, especially in applications where noise reduction is critical.

v belt double teeth

5. Versatility in Applications Due to their unique design, double teeth V-belts are suitable for various applications, including automotive drive systems, agricultural machinery, and more. Their ability to adapt to different environments and demands makes them a preferred choice for engineers and designers.

Choosing the Right V-Belt

When selecting a V-belt for a specific application, it is essential to consider several factors

- Load Requirements Understanding the load and power requirements of your system is crucial. Double teeth belts are particularly beneficial in high-load scenarios.

- Operating Environment Consider environmental factors such as temperature, humidity, and exposure to chemicals. The material of the belt should be compatible with the operating conditions.

- Belt Length and Width Ensure that the belt's dimensions conform to the specifications of the pulleys it will be used with. Accurate measurements will enhance performance and efficiency.

- Manufacturer Specifications Always refer to the manufacturer's guidelines regarding installation, maintenance, and usage. Following these recommendations can significantly extend the lifespan of the belt.

Conclusion

The double teeth V-belt represents a significant advancement in power transmission technology. With its improved power transfer capabilities, enhanced flexibility, better load distribution, and reduction in noise and vibration, it stands out as an excellent choice for various applications. As industries continue to evolve and demand more efficient systems, the use of innovative designs like the double teeth V-belt will likely become even more prevalent, forging a path toward greater mechanical performance and reliability. Understanding these advancements can help engineers and designers make informed decisions, ensuring optimal performance in their mechanical systems.

-

Upgrade Power Steering Pump Belt for Smooth, Quiet Operation

NewsAug.27,2025

-

Precision Timing Belt & Chain: Engine Performance & Durability

NewsAug.26,2025

-

Precision Lathe Drive Belts: Durable & Reliable Performance

NewsAug.25,2025

-

84.5 Serpentine Belt: Durable & Precision Fit for Your Engine

NewsAug.24,2025

-

Premium Ribbed Drive Belts for Quiet Power Transmission

NewsAug.23,2025

-

High-Performance Vehicle Timing Belt for Engine Precision

NewsAug.22,2025