- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Aug . 18, 2024 04:56 Back to list

Understanding Variable Speed Belt Drives for Enhanced Machinery Efficiency and Flexibility

Variable Speed Belt Drive Enhancing Efficiency in Mechanical Systems

In modern engineering applications, efficiency and adaptability are paramount. One of the innovative solutions that has emerged to meet these requirements is the variable speed belt drive system. This technology enables machines to operate at different speeds, optimizing performance and energy consumption.

Understanding Variable Speed Belt Drive

At its core, a variable speed belt drive consists of a system of pulleys and belts that transmit power from one component to another while allowing for adjustable speed ratios. The primary advantage of this system is its ability to modify the speed of the driven component without needing to replace or modify the motor. This feature is particularly useful in applications where processes require varying speeds to achieve the desired results.

Components of Variable Speed Belt Drives

A typical variable speed belt drive system comprises several key components

1. Pulleys These are the circular components around which the belt moves. In a variable speed system, pulleys are often designed with varying diameters or adjustable surfaces to change effective speed ratios.

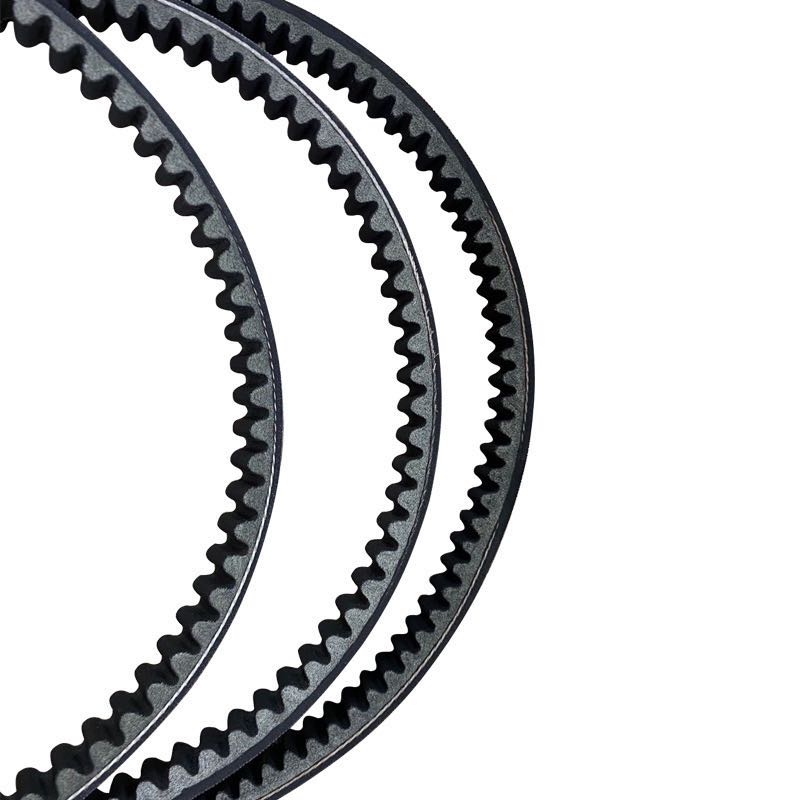

2. Belt This is the flexible component that connects the pulleys and transmits power from one to the other. Variable-speed belts may be made from materials that allow for higher flexibility and durability.

3. Tensioning Mechanism To maintain optimal contact between the belt and the pulleys, a tensioning mechanism adjusts the tightness of the belt, which is crucial for effective power transmission.

variable speed belt drive

4. Motor The driving force behind the belt drive system, the motor provides the necessary energy to rotate the pulleys and move the belt.

Applications and Benefits

Variable speed belt drives are widely used across various industries, including manufacturing, automotive, and HVAC systems. Here are some key benefits

1. Energy Efficiency By enabling machines to operate at the optimal speed for specific tasks, variable speed belt drives significantly reduce energy consumption. For instance, in HVAC systems, adjusting fan speeds leads to lower energy costs and reduced wear on components.

2. Improved Process Control The ability to change speeds precisely allows for better control over manufacturing processes. This flexibility can lead to enhanced product quality and less waste, as machines can be fine-tuned to meet production demands.

3. Smoother Operations Variable speed drives can minimize mechanical shocks and vibrations associated with sudden speed changes, promoting a smoother operation and extending the lifespan of machinery.

4. Reduced Maintenance By allowing components to operate more efficiently and reducing the wear and tear associated with fixed-speed operations, these systems can lead to lower maintenance costs and downtime.

Conclusion

Variable speed belt drives represent a significant advancement in mechanical engineering, providing the flexibility and efficiency required in today’s competitive landscape. Their ability to adapt to varying operational demands not only optimizes performance but also contributes to sustainability by reducing energy consumption. As industries continue to seek ways to improve efficiency and reduce their environmental impact, the adoption of variable speed belt drive systems is likely to grow. With ongoing advancements in materials and technology, we can expect even more innovative applications that harness the benefits of this versatile drive system in the near future.

-

Upgrade Power Steering Pump Belt for Smooth, Quiet Operation

NewsAug.27,2025

-

Precision Timing Belt & Chain: Engine Performance & Durability

NewsAug.26,2025

-

Precision Lathe Drive Belts: Durable & Reliable Performance

NewsAug.25,2025

-

84.5 Serpentine Belt: Durable & Precision Fit for Your Engine

NewsAug.24,2025

-

Premium Ribbed Drive Belts for Quiet Power Transmission

NewsAug.23,2025

-

High-Performance Vehicle Timing Belt for Engine Precision

NewsAug.22,2025