- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Jul . 23, 2024 14:55 Back to list

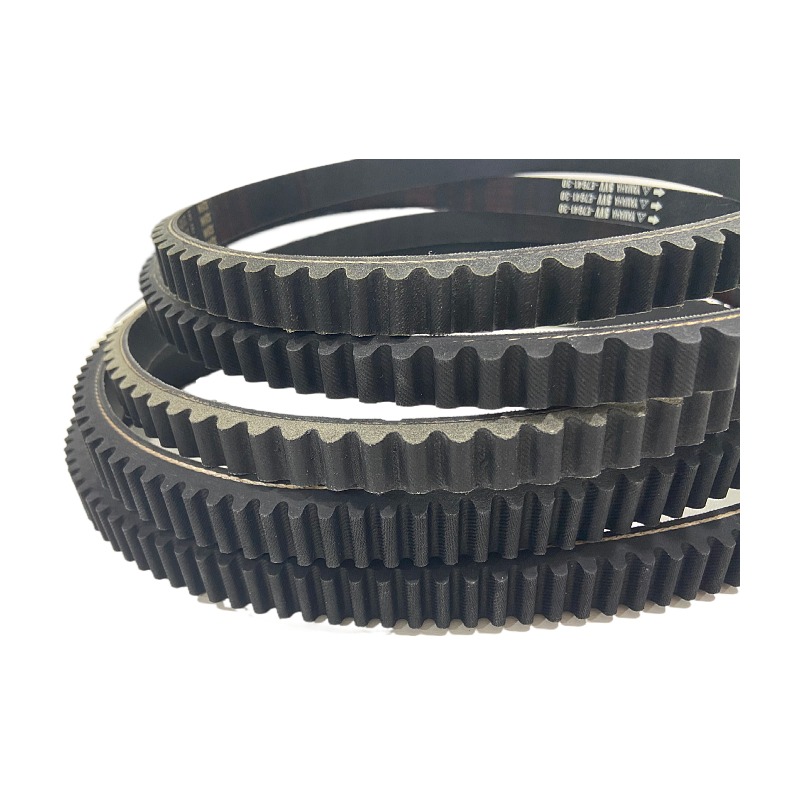

Understanding the Benefits and Applications of Poly V Belts in Modern Machinery and Equipment

Understanding Poly V Belts The Key to Efficient Power Transmission

In the realm of mechanical engineering and automotive applications, the importance of reliable power transmission cannot be overstated. Among various components that facilitate this process, poly V belts, often referred to as serpentine belts or multi-rib belts, have garnered significant attention due to their efficiency and versatility. This article delves into the construction, functionality, advantages, and applications of poly V belts, shedding light on why they have become a preferred choice in many machines and vehicles.

Construction of Poly V Belts

Poly V belts are characterized by their unique design, featuring multiple longitudinal ribs that run parallel to the length of the belt. This ribbed structure provides a larger surface area for contact with the pulleys than traditional V-belts, allowing for improved grip and power transmission. Constructed from a combination of rubber and other materials, poly V belts are engineered to provide flexibility, strength, and resistance to wear and tear. The design allows them to operate smoothly over pulleys of varying diameters while maintaining a high level of efficiency.

Functionality and Mechanism

The primary function of poly V belts is to transfer power from one component to another, typically from a motor to various accessories such as alternators, water pumps, or air conditioning compressors. When the motor turns, the belt moves in synchronization, driving these components effectively. The ribbed design enables the belt to fit snugly into the grooves of the pulleys, enhancing traction and minimizing slippage, which is critical for maintaining performance standards.

Another noteworthy feature of poly V belts is their ability to accommodate multiple accessories. Unlike traditional V-belts, which require separate belts for different components, a single poly V belt can drive several accessories simultaneously. This not only simplifies the design of the mechanical system but also reduces maintenance requirements and overall weight, contributing to improved fuel efficiency in automotive applications.

Advantages of Poly V Belts

poly v belts

1. Higher Efficiency One of the most significant advantages of poly V belts is their high efficiency in power transmission. Their design minimizes energy loss due to slippage, ensuring that more power is effectively transferred from the engine to the accessory.

2. Compact and Lightweight Poly V belts occupy less space and weigh less than traditional V-belts, making them suitable for modern applications where space and weight are critical constraints, such as in automotive design.

3. Reduced Noise and Vibration The smooth operation of poly V belts contributes to a quieter running machine. This is particularly beneficial in automotive applications where noise reduction is a key consideration for consumer comfort.

4. Longer Lifespan Due to their durable construction and materials, poly V belts tend to last longer than conventional belts. This longevity can lead to fewer replacements and lower maintenance costs over time.

Applications

The applications of poly V belts are vast and varied. In the automotive sector, they are commonly found in a wide range of vehicles, from compact cars to heavy-duty trucks. Beyond automotive uses, poly V belts are also utilized in industrial machinery, pumping stations, and HVAC systems, where efficient power transmission is essential.

In conclusion, poly V belts play a crucial role in modern mechanical systems by providing efficient, reliable, and compact power transmission solutions. Their unique design and numerous advantages make them a vital component across diverse applications. As technology continues to evolve, we can expect further innovations in belt design and materials that will enhance their performance and applicability, solidifying their place in the future of mechanical engineering and automotive design.

-

Upgrade Power Steering Pump Belt for Smooth, Quiet Operation

NewsAug.27,2025

-

Precision Timing Belt & Chain: Engine Performance & Durability

NewsAug.26,2025

-

Precision Lathe Drive Belts: Durable & Reliable Performance

NewsAug.25,2025

-

84.5 Serpentine Belt: Durable & Precision Fit for Your Engine

NewsAug.24,2025

-

Premium Ribbed Drive Belts for Quiet Power Transmission

NewsAug.23,2025

-

High-Performance Vehicle Timing Belt for Engine Precision

NewsAug.22,2025