- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Aug . 16, 2024 09:55 Back to list

Understanding Mechanical Drives and Belt Systems for Efficient Power Transmission

Mechanical Drives and Belting An Overview

Mechanical drives and belting systems play a critical role in the operation of machinery across various industries, ranging from automotive to manufacturing. They are fundamental components that facilitate power transmission, enabling machines to perform their intended functions effectively. Understanding the characteristics and applications of these systems can provide insights into their importance in modern engineering.

At its core, a mechanical drive is a system that transmits power from one part of a machine to another. This is typically achieved through various forms of mechanical energy transfer, including gears, pulleys, or belts. Among these, belting systems are particularly noteworthy due to their versatility and efficiency in transmitting power over distances.

Types of Mechanical Drives

Mechanical drives can be classified into several categories, including

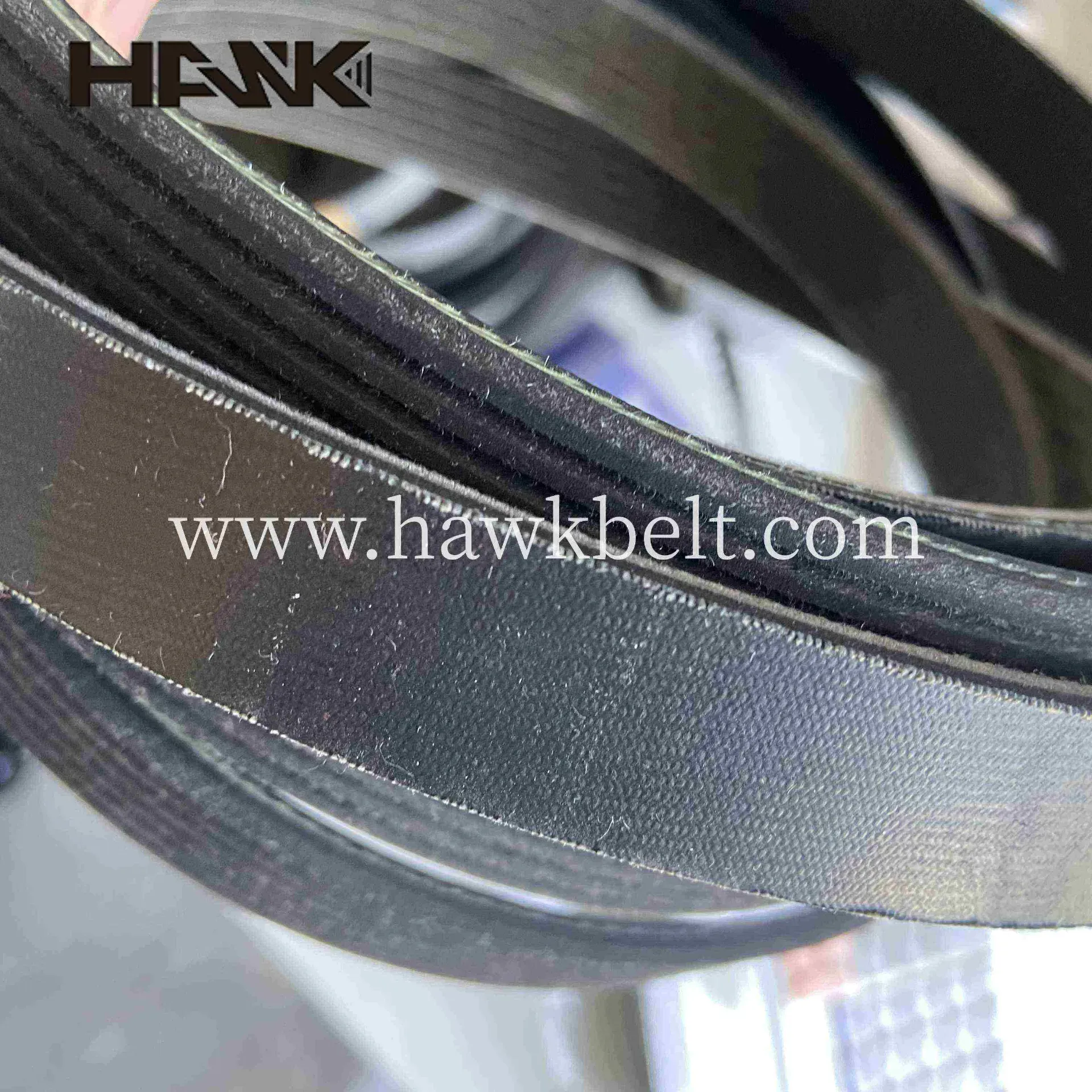

1. Belt Drives These systems use flexible belts, usually made of rubber or synthetic materials, to transmit power between pulleys. Belt drives are celebrated for their ability to handle large power loads while maintaining low noise levels and minimal vibration.

2. Chain Drives Utilizing chains made from metal links, chain drives offer a robust solution for power transmission, especially when dealing with heavy machinery. They are capable of transmitting high torque and are often used in applications such as bicycles and motorcycles.

3. Gear Drives Gears, with their interlocking teeth, provide direct power transmission, making them highly efficient. Gear drives are commonly found in automotive transmissions and industrial machines due to their compact design and ability to handle serious power loads.

Advantages of Belting Systems

Belt drives, a significant aspect of mechanical drives, offer numerous benefits that make them a popular choice for many applications

- Cost-Effectiveness Compared to some other mechanical drive systems, belt drives tend to be more affordable to implement and maintain. This makes them ideal for smaller operations or budget-conscious projects.

mechanical drives & belting

- Flexibility in Design Belting systems can easily adapt to changing layouts or needs, allowing for modifications in machine design without extensive changes to the drive system itself

.- Noise and Vibration Reduction The inherent flexibility of belts provides a quieter operation compared to rigid systems. This is particularly advantageous in environments where noise reduction is a priority.

- Slippage Tolerance Belts can handle minor misalignments between pulleys, making them more forgiving than rigid drive systems. This tolerance helps in prolonging equipment life and reducing wear.

Applications of Mechanical Drives and Belting Systems

The applications of mechanical drives and belts are vast and varied

- Manufacturing Automation Conveyor belts are a prominent example, allowing for the efficient movement of materials and products along assembly lines.

- Agricultural Machinery Equipment such as tractors and harvesters utilize belting systems to transfer power from engines to various components, facilitating efficient operation.

- Consumer Products Items like washing machines and lawnmowers often employ belt drives due to their reliability and low-noise performance.

Future Trends

As technology continues to evolve, so do the designs and materials used in mechanical drives and belting systems. Innovations such as the development of advanced composite materials and smart drive systems incorporating sensors for real-time monitoring are paving the way for greater efficiency and reliability.

In conclusion, mechanical drives and belting systems are essential to modern industry, providing versatile, efficient, and cost-effective power transmission solutions. Their widespread application across various sectors demonstrates their continued relevance and significance in mechanical engineering. Understanding these systems not only enhances our comprehension of machinery but also underscores the critical role they play in technological advancement.

-

Upgrade Power Steering Pump Belt for Smooth, Quiet Operation

NewsAug.27,2025

-

Precision Timing Belt & Chain: Engine Performance & Durability

NewsAug.26,2025

-

Precision Lathe Drive Belts: Durable & Reliable Performance

NewsAug.25,2025

-

84.5 Serpentine Belt: Durable & Precision Fit for Your Engine

NewsAug.24,2025

-

Premium Ribbed Drive Belts for Quiet Power Transmission

NewsAug.23,2025

-

High-Performance Vehicle Timing Belt for Engine Precision

NewsAug.22,2025