- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Jan . 09, 2025 12:05 Back to list

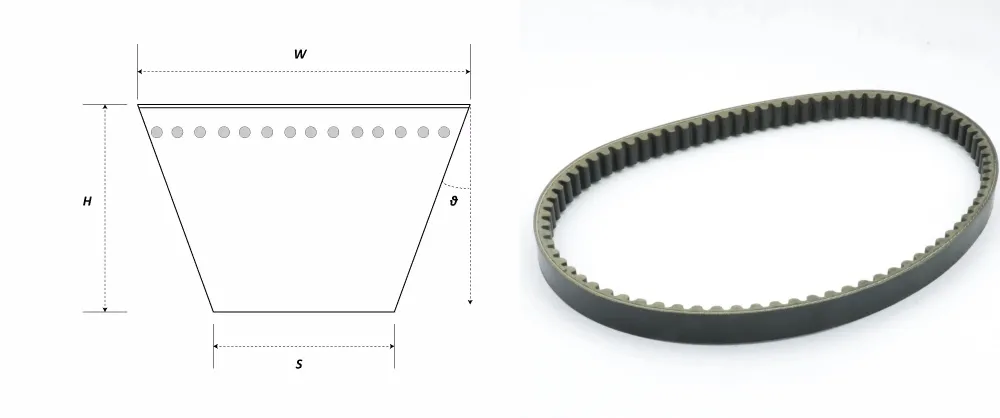

toothed drive belts

Toothed drive belts, known for their unique design and high performance, have become transformative in the world of industrial machinery and automotive technologies. These precision-engineered components are valued for their reliability and efficiency, offering unique advantages in various applications where timing and precision are critical.

Recent advancements in toothed drive belt technology have further cemented their authoritativeness in the industry. For instance, the integration of specialized coatings and materials has enhanced their thermal and chemical resistance, enabling use in various environments that were previously unsuitable. Today's toothed drive belts perform effectively in extreme temperatures and exposure to oils and chemicals, making them indispensable in industrial sectors such as petrochemicals and food processing. Trustworthiness of toothed drive belts is also demonstrated through rigorous testing and quality standards adhered to by leading manufacturers. Products from reputable brands undergo comprehensive testing for tensile strength, elongation, and fatigue resistance, ensuring they meet or exceed international standards. For engineers and procurement specialists, choosing these high-quality belts from trusted suppliers ensures minimal downtime and maintenance, thereby securing operational continuity. In summary, toothed drive belts are not just components but pivotal elements that influence the operational success of complex systems. Their precision, durability, and adaptability to demanding environments underscore their importance in industries that prioritize efficiency and reliability. By investing in high-quality toothed drive belts and leveraging the latest technological enhancements, companies can enhance their machinery performance and maintain a competitive edge in their respective markets.

Recent advancements in toothed drive belt technology have further cemented their authoritativeness in the industry. For instance, the integration of specialized coatings and materials has enhanced their thermal and chemical resistance, enabling use in various environments that were previously unsuitable. Today's toothed drive belts perform effectively in extreme temperatures and exposure to oils and chemicals, making them indispensable in industrial sectors such as petrochemicals and food processing. Trustworthiness of toothed drive belts is also demonstrated through rigorous testing and quality standards adhered to by leading manufacturers. Products from reputable brands undergo comprehensive testing for tensile strength, elongation, and fatigue resistance, ensuring they meet or exceed international standards. For engineers and procurement specialists, choosing these high-quality belts from trusted suppliers ensures minimal downtime and maintenance, thereby securing operational continuity. In summary, toothed drive belts are not just components but pivotal elements that influence the operational success of complex systems. Their precision, durability, and adaptability to demanding environments underscore their importance in industries that prioritize efficiency and reliability. By investing in high-quality toothed drive belts and leveraging the latest technological enhancements, companies can enhance their machinery performance and maintain a competitive edge in their respective markets.

Share:

Next:

Latest news

-

Durable Diesel Engine Belt with GPT-4-Turbo AI Tech | Precision Fit

NewsAug.04,2025

-

High-Quality Tensioner Belt Pulley - Durable & Efficient

NewsAug.03,2025

-

Premium Timing Belt Factory | AI-Optimized Solutions

NewsAug.02,2025

-

Premium Custom V Belts Enhanced with GPT-4 Turbo AI

NewsAug.01,2025

-

Car Serpentine Belt: AI-Optimized Performance with GPT-4-Turbo

NewsJul.31,2025

-

Heat Joining Drive Belt | High-Durability Fusion Solution

NewsJul.31,2025