- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Jul . 29, 2024 05:28 Back to list

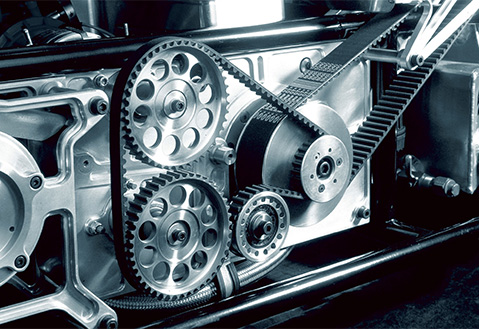

Replacement Motor Belt and Fan Belt 10PK for Reliable Performance in Your Vehicle's Engine System

Understanding the Importance of Motor Belts and Fan Belts A Focus on the 10PK Specification

Motor belts and fan belts are crucial components in various machinery, particularly in automotive and industrial applications. Among the different types available, the 10PK belt is a well-known specification that plays an essential role in the efficient operation of engines and other systems. This article explores the significance of motor belts and fan belts, emphasizing the 10PK variant, and discusses how they contribute to the functionality and longevity of equipment.

What are Motor Belts and Fan Belts?

Motor belts, commonly referred to as serpentine belts or drive belts, are essential for transferring power from the engine's crankshaft to various components. These may include alternators, power steering pumps, water pumps, air conditioning compressors, and more. A fan belt, usually a specific type of motor belt, is primarily responsible for driving cooling fans in the engine compartment. Although the terms are often used interchangeably, understanding the specific role of each belt can help in maintenance and repair practices.

The 10PK Specification Explained

The designation 10PK refers to a specific measurement of the belt's width and the number of ribs it has. In this case, 10 indicates the number of ribs, while PK stands for a specific profile of the belt. The ribbed design allows for greater surface area contact between the belt and the pulleys, which enhances grip and power transmission efficiency. The 10PK belt is prevalent in various applications due to its robustness and reliable performance under high-stress situations.

Importance of the 10PK Belt in Automotive Systems

motor belt\/fan belt 10pk

In automotive systems, the 10PK motor belt plays a critical role in ensuring the engine operates smoothly. This belt is typically used in vehicles that require additional power for multiple components, such as higher-capacity alternators or advanced air conditioning systems. The increased efficiency provided by the 10 rib design means that vehicles equipped with a 10PK belt can achieve better performance while consuming less energy.

When it comes to vehicle maintenance, the 10PK belt is often subject to wear and tear due to constant friction, heat, and environmental factors. Regular inspection of this belt is imperative to avoid sudden failures that can lead to costly repairs and potential hazards on the road. Signs of wear may include cracks, fraying, or glazing on the belt surface, which indicates that it is time for a replacement.

Benefits of Using Quality 10PK Belts

Investing in high-quality 10PK belts can significantly impact the performance of your vehicle or equipment. Quality belts are designed to withstand various operating conditions, including extreme temperatures and loads. They maintain their flexibility and tensile strength over time, reducing the likelihood of premature failure. Additionally, many manufacturers offer warranties on their belts, providing peace of mind for consumers.

Furthermore, using a durable 10PK belt can enhance the overall efficiency of the system by ensuring optimal power transfer. This translates to better fuel efficiency in vehicles and less energy consumption in industrial applications, ultimately contributing to lower operational costs.

Conclusion

In conclusion, motor belts and fan belts, particularly the 10PK specification, are vital components for the effective operation of automotive and industrial systems. Understanding their importance not only aids in proper maintenance but also highlights the value of selecting high-quality belts for replacement. Regular inspections, coupled with timely replacements, can ensure that your systems run smoothly and efficiently, prolonging their lifespan and saving you money in the long run. Whether you are an automotive enthusiast or a facility manager, prioritizing the integrity of your motor and fan belts will undoubtedly lead to better performance and reliability in your operations.

-

Upgrade Power Steering Pump Belt for Smooth, Quiet Operation

NewsAug.27,2025

-

Precision Timing Belt & Chain: Engine Performance & Durability

NewsAug.26,2025

-

Precision Lathe Drive Belts: Durable & Reliable Performance

NewsAug.25,2025

-

84.5 Serpentine Belt: Durable & Precision Fit for Your Engine

NewsAug.24,2025

-

Premium Ribbed Drive Belts for Quiet Power Transmission

NewsAug.23,2025

-

High-Performance Vehicle Timing Belt for Engine Precision

NewsAug.22,2025