- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Nov . 01, 2024 00:59 Back to list

Exploring the Efficiency and Applications of Power Transmission Belts in Modern Machinery

Power Transmission Belts An Essential Component in Mechanical Engineering

Power transmission belts are a crucial aspect of mechanical engineering, playing a vital role in the efficient transfer of power from one component to another within various machinery systems. These belts serve a wide range of applications, from small appliances to large industrial machines, and are instrumental in ensuring that operations run smoothly and efficiently.

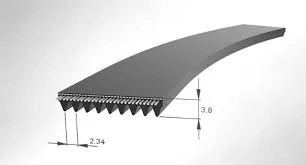

One of the primary types of power transmission belts is the V-belt. Characterized by its trapezoidal cross-section, the V-belt is designed to operate on V-shaped pulleys, providing a significant amount of grip and reducing slippage. This design enables the belt to transmit power effectively while maintaining flexibility, making it a popular choice for various applications, including HVAC systems, automotive engines, and conveyor systems.

Another commonly used type is the synchronous belt, often referred to as a timing belt. Unlike V-belts, synchronous belts feature teeth that mesh with corresponding grooves on pulleys. This design allows for precise synchronization of drives, making them ideal for applications requiring accurate timing, such as in printers, automotive camshafts, and robotic systems. Their capacity to maintain timing without slippage enhances efficiency and reliability.

power transmission belts

Flat belts are also used in power transmission, particularly in older machinery. Their simple design allows them to transmit power over longer distances with minimal maintenance. However, they are more prone to slippage than V-belts and synchronous belts, making them less common in modern applications where efficiency and power transmission reliability are paramount.

The materials used in power transmission belts are also critical to their performance. Rubber is commonly used due to its elasticity and ability to withstand wear. For high-torque applications, belts may be reinforced with materials such as polyester or steel cords to enhance strength and durability. The choice of material affects not only the belt's lifespan but also its ability to operate under various environmental conditions, such as temperature and humidity.

In addition to their functional importance, regular maintenance and inspection of power transmission belts are essential to ensure optimal performance. Worn or damaged belts can lead to inefficiencies, increased energy consumption, and even machinery failure. Therefore, businesses and operators must prioritize the monitoring of belt conditions and timely replacements to maintain productivity and safety.

In conclusion, power transmission belts are indispensable in the field of mechanical engineering. Their diverse types and materials cater to various industrial and commercial applications, facilitating efficient power transfer and operational reliability. As technology advances, the development of new materials and designs will continue to enhance the performance and longevity of power transmission belts, ensuring their integral role in modern machinery systems.

-

Upgrade Power Steering Pump Belt for Smooth, Quiet Operation

NewsAug.27,2025

-

Precision Timing Belt & Chain: Engine Performance & Durability

NewsAug.26,2025

-

Precision Lathe Drive Belts: Durable & Reliable Performance

NewsAug.25,2025

-

84.5 Serpentine Belt: Durable & Precision Fit for Your Engine

NewsAug.24,2025

-

Premium Ribbed Drive Belts for Quiet Power Transmission

NewsAug.23,2025

-

High-Performance Vehicle Timing Belt for Engine Precision

NewsAug.22,2025