- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Dec . 17, 2024 15:40 Back to list

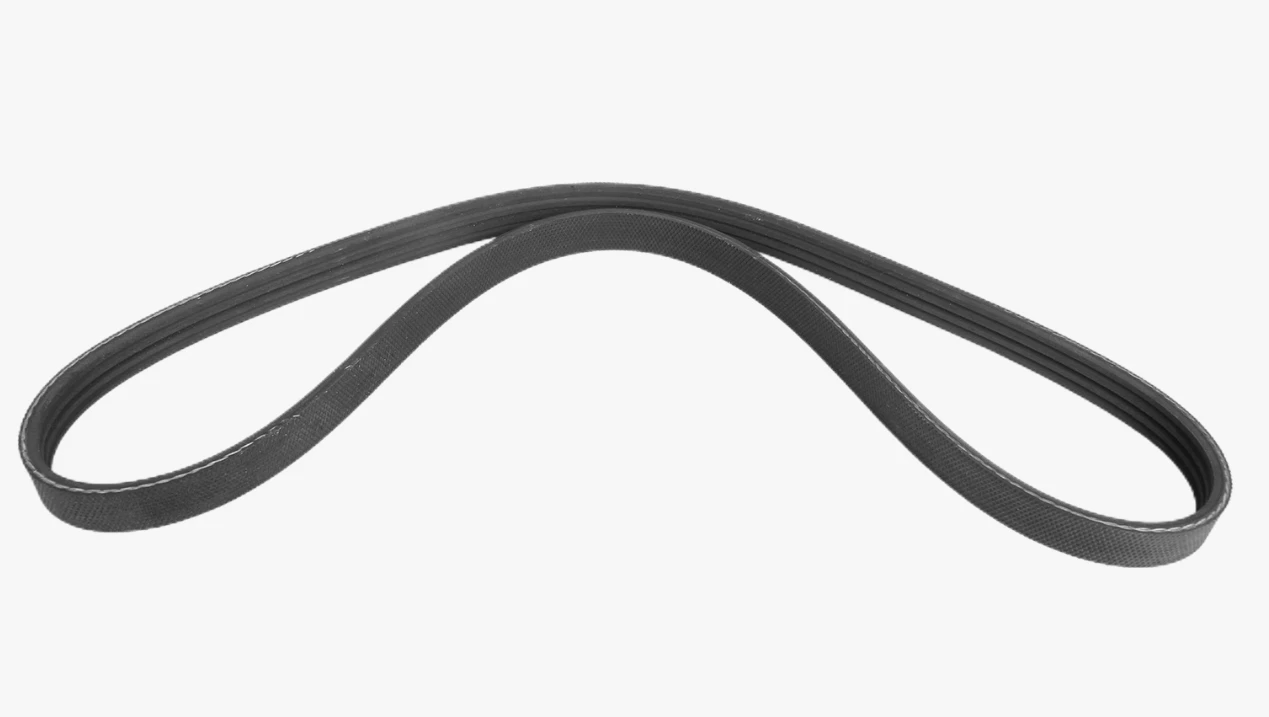

Understanding the Benefits and Applications of Poly Vee Belts in Modern Machinery

Understanding Poly Vee Belts Design, Function, and Applications

Poly Vee belts, also known as poly-V belts or serpentine belts, are an essential component in the automotive and industrial machinery sectors. They are a type of synchronous belt characterized by their unique V shape that allows for efficient power transmission. In this article, we will explore the design, functionality, and various applications of poly vee belts, highlighting their significance in modern mechanical systems.

Design of Poly Vee Belts

Poly vee belts are made from high-quality rubber compounds and are reinforced with various materials like polyester or Kevlar for added strength. The distinct features of these belts include a series of longitudinal ribs that run along the belt's length, making them flexible and capable of gripping pulleys effectively. This design allows poly vee belts to transmit power efficiently, even in tight spaces where traditional belts might struggle.

The most notable aspect of poly vee belts is their cross-section, which resembles a V shape. This design ensures a larger surface area contact with the pulley’s groove, enhancing grip and reducing slippage. Furthermore, poly vee belts can engage multiple pulleys simultaneously, making them a versatile choice for many applications.

Functionality

The primary function of a poly vee belt is power transmission. When installed in an engine or machinery setup, the belt connects various components, such as the alternator, air conditioning compressor, and water pump. As the engine runs, the crankshaft drives the poly vee belt, which in turn rotates the connected components, ensuring the efficient functioning of the entire system.

poly vee belt

One of the main advantages of poly vee belts over traditional flat belts is their ability to handle high-speed operations and varying load conditions. Their ribbed design facilitates quick direction changes without significant loss of power, making them ideal for dynamic environments. Additionally, poly vee belts are less prone to stretching and wear, resulting in a longer operational lifespan.

Applications

Poly vee belts are widely used in various applications, primarily in the automotive industry. In vehicles, they are responsible for driving multiple accessories from a single pulley system. This not only simplifies the engine design but also reduces weight and enhances fuel efficiency. The versatility of poly vee belts allows them to be used in different vehicle types, from passenger cars to heavy-duty trucks.

Beyond automotive applications, poly vee belts are also employed in industrial machinery. They are often found in conveyor systems, manufacturing equipment, and agricultural machinery. In these settings, poly vee belts enable smooth power transmission, ensuring the reliability and efficiency of operational processes.

Furthermore, the growing demand for energy-efficient solutions has led to an increase in the adoption of poly vee belts in renewable energy systems, such as wind turbines and solar panel mechanisms. Their capacity to manage power transmission in various orientations and conditions makes them a preferred choice in these innovative technologies.

Conclusion

In summary, poly vee belts represent a significant advancement in power transmission technology. Their unique design, exceptional functionality, and wide-ranging applications make them indispensable in both automotive and industrial contexts. As industries continue to evolve, the role of poly vee belts in enabling efficient and reliable operations cannot be overstated. Whether in the heart of an engine or the mechanisms of industrial equipment, poly vee belts are a key player in driving progress forward. Understanding their importance and functionality is crucial for engineers and technicians aiming to optimize performance in their respective fields. As technology advances, we can expect further innovations in belt design and materials, ensuring that poly vee belts continue to meet the demands of the future.

-

Upgrade Power Steering Pump Belt for Smooth, Quiet Operation

NewsAug.27,2025

-

Precision Timing Belt & Chain: Engine Performance & Durability

NewsAug.26,2025

-

Precision Lathe Drive Belts: Durable & Reliable Performance

NewsAug.25,2025

-

84.5 Serpentine Belt: Durable & Precision Fit for Your Engine

NewsAug.24,2025

-

Premium Ribbed Drive Belts for Quiet Power Transmission

NewsAug.23,2025

-

High-Performance Vehicle Timing Belt for Engine Precision

NewsAug.22,2025