- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Nov . 16, 2024 13:20 Back to list

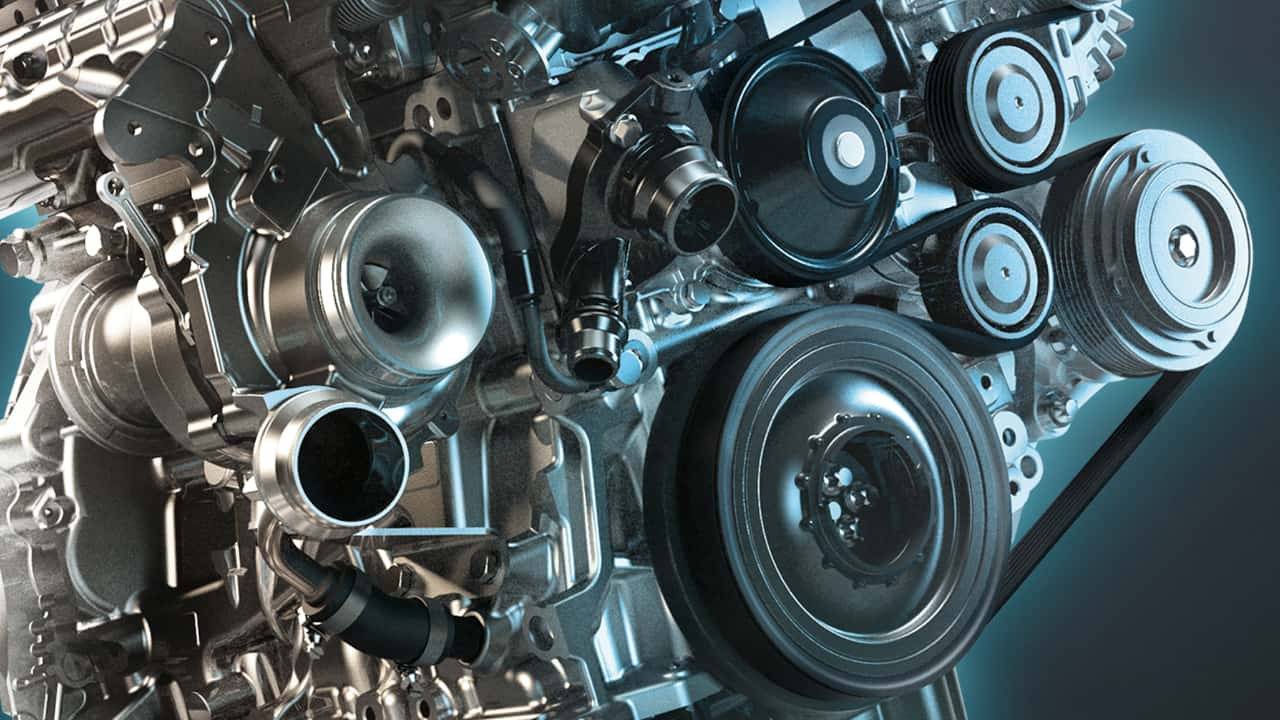

Understanding EPDM PK Belt Sizes for Optimal Performance and Fit

Understanding PK Belt Sizes and the Benefits of EPDM Belts

In the realm of industrial machinery and automotive applications, the importance of choosing the right belt cannot be overstated. One popular choice among engineers and manufacturers is the PK belt, particularly those made with Ethylene Propylene Diene Monomer (EPDM) rubber. This article sheds light on PK belt sizes and the advantages of EPDM belts.

What are PK Belts?

PK belts are a type of flat rubber belt that is characterized by their trapezoidal profile. Commonly used in various applications, they are known for their flexibility, durability, and ability to transmit power effectively. The “P” in PK typically stands for “profile,” referring to the belt’s shape. PK belts are often utilized in applications such as conveyor systems, automotive engines, and agricultural machinery, where efficient power transfer is critical.

Understanding PK Belt Sizes

When choosing PK belts, it's crucial to consider the size, as this affects compatibility with pulleys and overall performance. PK belt sizes are designated by a combination of letters and numbers that denote the belt’s width, length, and profile. For example, PK belts may be labeled as PK 10, PK 15, or PK 20, with the number indicating the belt's width in millimeters.

pk belt sizes\/pk belt with epdm

The length of PK belts can vary significantly, which allows for flexibility when designing or replacing components in mechanical systems. To calculate the required length, one must measure the distance around the pulleys and take into account the tensioning methods employed in the system. It's essential to consult manufacturer guidelines for specific size recommendations, ensuring optimal performance and longevity.

The Advantages of EPDM Belts

One of the standout features of PK belts is their construction material. Many modern PK belts are made from EPDM rubber, which offers a range of benefits. EPDM is known for its excellent resistance to heat, ozone, and weathering, making it ideal for outdoor applications and environments where exposure to harsh conditions is prevalent. This intrinsic durability helps EPDM belts maintain their performance over time, reducing the need for frequent replacements.

Additionally, EPDM belts exhibit good flexibility and tensile strength, allowing them to perform efficiently under tension without succumbing to wear and tear easily. This characteristic is especially beneficial in applications that require continuous movement and load-bearing functions. Furthermore, the chemical resistance of EPDM makes these belts suitable for use in industries dealing with aggressive substances, adding to their versatility.

Conclusion

In summary, understanding PK belt sizes is pivotal for effective industrial and automotive operation. Choosing the right belt ensures compatibility and optimal performance. The incorporation of EPDM into PK belts enhances their durability and versatility, allowing them to withstand harsh conditions and demanding applications. By investing in EPDM PK belts, manufacturers can enhance the reliability of their machinery, reduce maintenance costs, and improve overall operational efficiency. Whether for conveyor systems or automotive engines, the selection of the right belt size and material can significantly impact productivity and performance.

-

Upgrade Power Steering Pump Belt for Smooth, Quiet Operation

NewsAug.27,2025

-

Precision Timing Belt & Chain: Engine Performance & Durability

NewsAug.26,2025

-

Precision Lathe Drive Belts: Durable & Reliable Performance

NewsAug.25,2025

-

84.5 Serpentine Belt: Durable & Precision Fit for Your Engine

NewsAug.24,2025

-

Premium Ribbed Drive Belts for Quiet Power Transmission

NewsAug.23,2025

-

High-Performance Vehicle Timing Belt for Engine Precision

NewsAug.22,2025