- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Nov . 20, 2024 12:46 Back to list

pk belt alternator

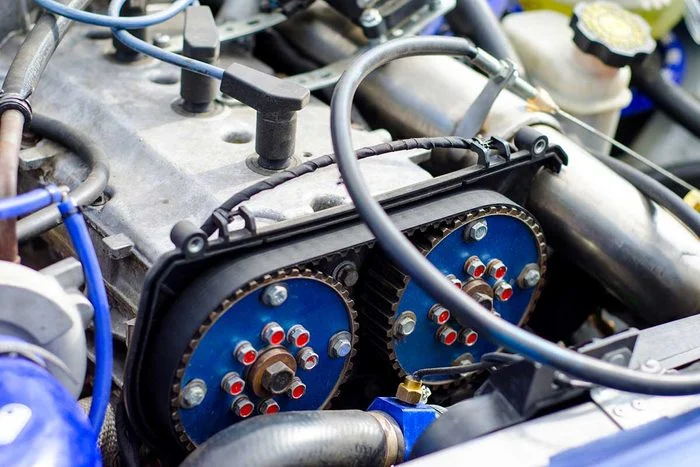

Understanding the PK Belt Alternator A Comprehensive Guide

The PK belt alternator is an essential component in modern automotive systems, playing a crucial role in generating electricity for vehicle operations. As cars become more reliant on electronic systems, understanding the function and importance of the PK belt alternator is more critical than ever.

What is a PK Belt?

The PK belt, often referred to as a serpentine belt or a drive belt, is a rubber belt used in a wide range of vehicles to drive multiple peripheral devices such as the alternator, power steering pump, water pump, and air conditioning compressor. The PK designation indicates a specific profile that allows for a tighter fit and improved efficiency compared to traditional belts. It has a ribbed design that enhances its grip and reduces slippage, ensuring optimal performance of the components it drives.

Function of the Alternator

The primary function of the alternator is to convert mechanical energy into electrical energy. As the engine runs, the serpentine belt spins the alternator's rotor, generating electricity through electromagnetic induction. This electricity is crucial for powering the vehicle's electrical systems, including the ignition system, lights, and infotainment systems. Moreover, the alternator charges the vehicle's battery, ensuring that it remains ready for the next engine start.

Why Choose a PK Belt Alternator?

pk belt alternator

PK belts and alternators are engineered for efficiency and reliability. With advancements in technology, these belts are designed to endure higher loads and extended service intervals than their counterparts. They also reduce noise, vibration, and harshness (NVH), contributing to a smoother driving experience.

Moreover, the PK belt alternator setup is more compact, maximizing engine space while maintaining the necessary functionality. This design efficiency leads to better fuel economy and overall vehicle performance. Over time, switching to a PK belt can result in reduced maintenance costs due to the enhanced durability and longevity of both the belt and the alternator.

Maintenance and Issues

Despite their durability, PK belts and alternators require regular maintenance to ensure long-term performance. Drivers should routinely check for signs of wear, such as fraying or cracks in the belt. A slipping belt can lead to poor alternator performance and, consequently, a drained battery. Additionally, listening for unusual noises, such as squealing or grinding, can indicate problems with the alternator or the belt system.

If any issues are suspected, it is crucial to consult a qualified mechanic. Timely intervention can prevent minor problems from escalating into major repairs, safeguarding both the vehicle's electrical system and the overall functionality of the car.

Conclusion

In conclusion, the PK belt alternator is a vital component in modern vehicles, ensuring the efficient generation of electrical energy. Its design offers numerous advantages that enhance vehicle performance, reliability, and longevity. Regular maintenance and awareness of potential issues can help drivers maximize the benefits of their PK belt alternator, ensuring a seamless driving experience. As automotive technology continues to evolve, the importance of reliable components like the PK belt alternator will only grow.

-

Upgrade Power Steering Pump Belt for Smooth, Quiet Operation

NewsAug.27,2025

-

Precision Timing Belt & Chain: Engine Performance & Durability

NewsAug.26,2025

-

Precision Lathe Drive Belts: Durable & Reliable Performance

NewsAug.25,2025

-

84.5 Serpentine Belt: Durable & Precision Fit for Your Engine

NewsAug.24,2025

-

Premium Ribbed Drive Belts for Quiet Power Transmission

NewsAug.23,2025

-

High-Performance Vehicle Timing Belt for Engine Precision

NewsAug.22,2025