- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Oct . 07, 2024 17:43 Back to list

pk belt\/5pk belt

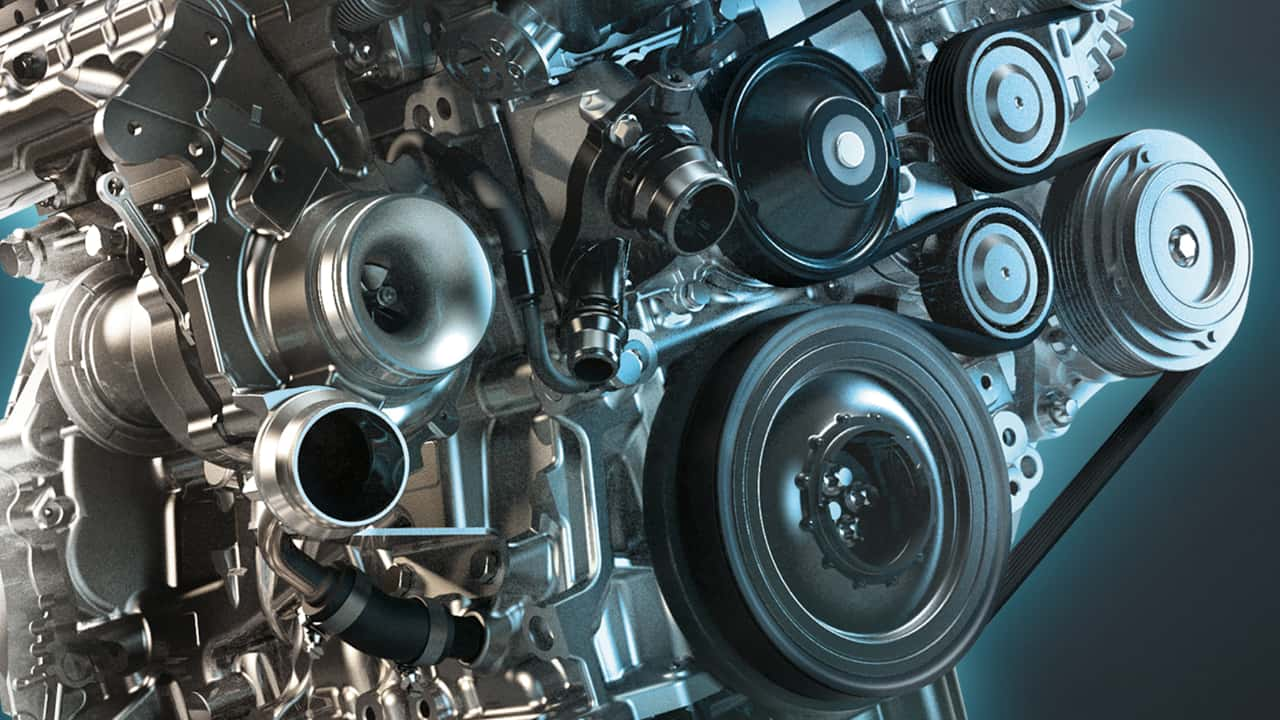

The Importance of Quality in PK Belt Selection

When it comes to industrial machinery, the PK belt, also known as the poly-vee belt or serpentine belt, is a crucial component that plays an integral role in the efficiency and performance of equipment. These belts, characterized by their unique V-shaped cross-sections, are designed to transmit power between various components in machines such as engines, conveyor systems, and various types of industrial equipment. Understanding the significance of high-quality PK belts, particularly the 5PK belt variant, can enhance performance while reducing downtime and maintenance costs.

Characteristics of 5PK Belts

The designation 5PK indicates that the belt contains five ribs, which provide an increased surface area for better grip and power transmission. This ribbed design allows for increased flexibility and reduces the chances of slippage, making it ideal for applications that require high torque and consistent performance. The construction of 5PK belts typically utilizes durable materials that are resistant to wear, temperature fluctuations, and oil, ensuring longevity and reliability, which are crucial for industrial operations.

The PK belt can be articulated for various applications that require different lengths or configurations. This versatility means that businesses can tailor their machinery to meet specific operational requirements while maintaining optimal efficiency. Whether used in automotive engines, agricultural machinery, or manufacturing equipment, the quality of the PK belting system can directly affect productivity and operational costs.

Benefits of Using High-Quality PK Belts

Choosing high-quality PK belts such as the 5PK variety brings several benefits to the table. First and foremost, the durability of these belts reduces the frequency of replacements required, leading to lower maintenance costs over time. Additionally, high-quality materials often translate to better resistance to environmental factors like temperature extremes, UV radiation, and chemical exposure.

This durability is complemented by an enhanced performance capability, which is critical for businesses that operate under high-stress conditions or require regular high-speed operation. A high-performing belt ensures that machines run smoothly, translating to increased productivity and efficiency.

pk belt\/5pk belt

The Cost Factor

While there may be cheaper options available on the market, it is essential to recognize that investing in high-quality PK belts, such as the 5PK, often results in significant long-term savings. Businesses may initially save money by opting for low-cost belts, but the trade-offs include increased wear and tear, higher maintenance costs, and potentially catastrophic equipment failures. The cost of equipment downtime can far exceed the upfront savings from purchasing inferior belts.

Furthermore, high-quality PK belts are engineered to work efficiently under varying loads and operating conditions. Their reliable performance ensures that machinery operates smoothly, which is indispensable for manufacturers who rely on a steady production flow. Consistency in performance not only maximizes productivity but also enhances the overall lifespan of the machinery involved.

Choosing the Right Supplier

When selecting PK belts, it is crucial to partner with reputable suppliers who specialize in high-quality industrial components. Companies that focus on quality assurance and customer support are more likely to provide belts that meet the necessary performance standards. Additionally, they can offer technical assistance in choosing the right belt for your specific application, ensuring an optimal fit that enhances performance.

Suppliers should also provide detailed product specifications, guidance on installation, and after-sales support. This can assist businesses in seamlessly integrating new belts into their existing machinery, minimizing any potential disruptions to their operations.

Conclusion

In conclusion, the significance of selecting high-quality PK belts, particularly the 5PK variant, cannot be overstated. The combination of enhanced durability, increased efficiency, and long-term cost savings makes these belts an invaluable choice for various industrial applications. As businesses continue to strive for operational excellence, investing in superior components like PK belts will undoubtedly play a key role in achieving those goals. By prioritizing quality and partnering with reputable suppliers, companies can ensure that their machinery operates at peak performance, driving productivity and reliability in an increasingly competitive marketplace.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025