- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Nov . 20, 2024 15:22 Back to list

nylon flat belt

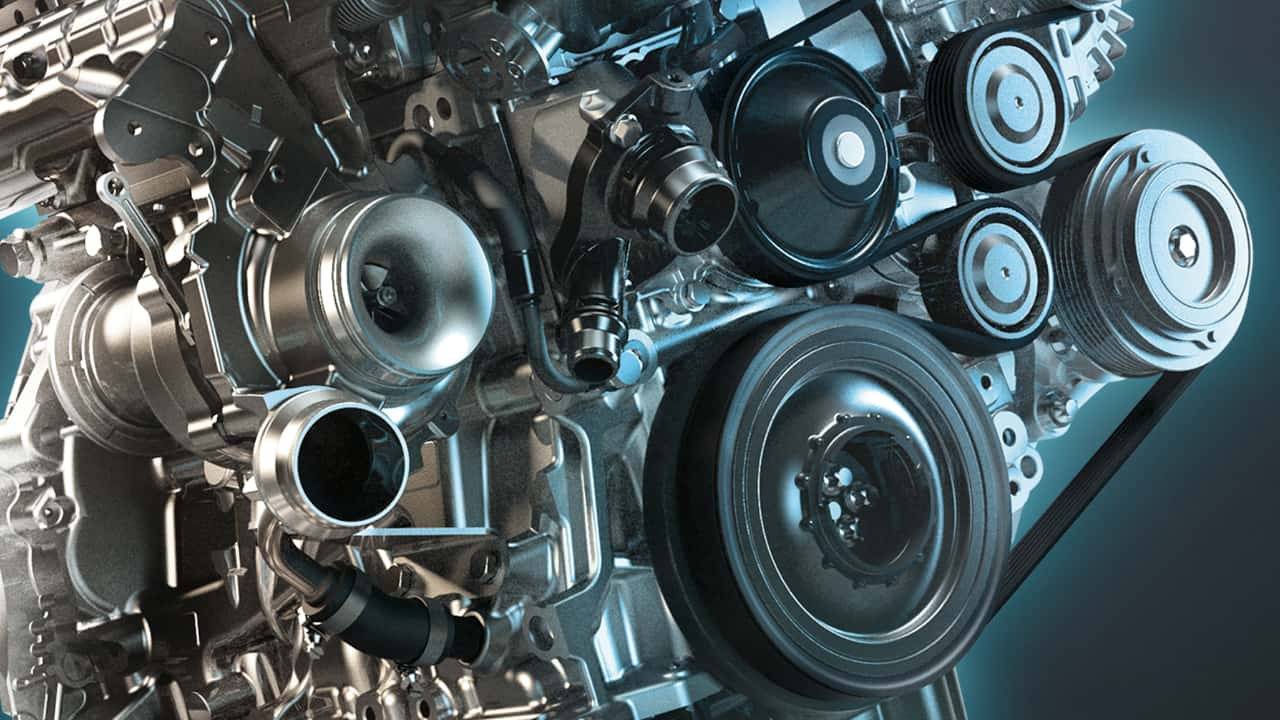

The Versatility and Importance of Nylon Flat Belts

Nylon flat belts are an essential component in various industrial applications, offering both durability and flexibility. As manufacturing processes have evolved, the need for reliable transmission systems has become increasingly important. Nylon flat belts provide an efficient solution, allowing for smoother operations in numerous settings.

Nylon, a synthetic polymer, was first introduced in the 1930s and quickly became popular due to its strength, elasticity, and resistance to wear and tear. When utilized in flat belts, nylon presents an array of benefits that make it a preferred choice in industries ranging from manufacturing to transportation.

One of the significant advantages of nylon flat belts is their incredible tensile strength. This strength ensures that the belts can handle substantial loads without stretching or breaking. As a result, they are particularly suited for conveyor systems, where consistent power transmission is critical. Whether in packaging facilities, assembly lines, or material handling systems, nylon flat belts can efficiently transport goods without the risk of failure under pressure.

In addition to their strength, nylon flat belts exhibit excellent flexibility and adaptability. They can easily bend around pulleys and other components, making them suitable for various configurations and applications. This flexibility also allows them to maintain performance in environments where space is limited or where complex movements are required.

nylon flat belt

Moreover, nylon flat belts are resistant to many environmental factors, including humidity, temperature fluctuations, and exposure to chemicals

. This resilience makes them ideal for applications in industries like food processing, pharmaceuticals, and textiles, where cleanliness and durability are paramount. In such settings, the ability to withstand harsh conditions helps to prolong the lifespan of the belts, reducing maintenance costs and downtime.Another key facet of nylon flat belts is their smooth surface, which minimizes friction between the belt and the pulleys. This quality significantly increases efficiency, as reduced friction translates into less energy consumption and lower operational costs. Additionally, improved efficiency means that machines can operate at higher speeds without the risk of damaging the belts, further enhancing productivity in manufacturing processes.

The versatility of nylon flat belts extends to their compatibility with different drive systems. They can be used in both power transmission and conveying applications, serving a dual purpose that can simplify inventory management and reduce costs. Furthermore, nylon flat belts can be customized in terms of width, thickness, and length, allowing businesses to tailor them to their specific needs easily.

As industries continue to advance toward automation and increased productivity, the role of nylon flat belts will remain vital. Their combination of strength, flexibility, durability, and efficiency makes them indispensable in modern manufacturing and material handling applications. Companies looking to optimize their operational efficiency would do well to consider the adoption of nylon flat belts, as they provide a reliable and cost-effective solution to meet the demands of today's fast-paced industrial environments.

In conclusion, nylon flat belts represent a perfect synthesis of engineering and material science, offering a range of benefits that make them suitable for a diverse array of applications. Their market presence is a testament to their role in enhancing productivity and efficiency across various sectors, showcasing the essential role they play in the machinery that powers our industries. Whether one is in manufacturing, logistics, or any field that relies on mechanical systems, understanding the importance of nylon flat belts is crucial for ensuring operational success.

-

Upgrade Power Steering Pump Belt for Smooth, Quiet Operation

NewsAug.27,2025

-

Precision Timing Belt & Chain: Engine Performance & Durability

NewsAug.26,2025

-

Precision Lathe Drive Belts: Durable & Reliable Performance

NewsAug.25,2025

-

84.5 Serpentine Belt: Durable & Precision Fit for Your Engine

NewsAug.24,2025

-

Premium Ribbed Drive Belts for Quiet Power Transmission

NewsAug.23,2025

-

High-Performance Vehicle Timing Belt for Engine Precision

NewsAug.22,2025