- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Nov . 24, 2024 05:58 Back to list

micro v belts

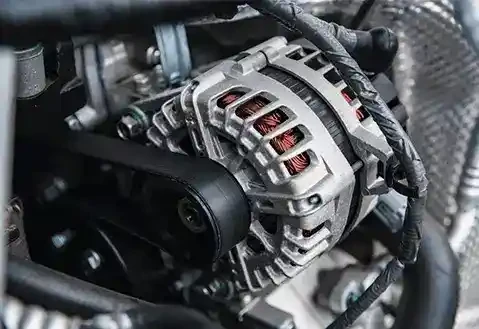

Understanding Micro V-Belts Their Importance and Applications

Micro V-belts, commonly known as serpentine belts, play a critical role in the operation of various automotive and industrial machinery. These belts are designed to transmit power from the engine’s crankshaft to multiple accessories, such as alternators, water pumps, power steering pumps, and air conditioning compressors. Given their crucial function, understanding the characteristics, advantages, and applications of micro V-belts is essential for both manufacturers and consumers.

What Are Micro V-Belts?

Micro V-belts are specially designed belts that feature a series of small grooves or ribs on their inner surface. This unique design enhances the belt's grip on the pulleys, thereby increasing its efficiency in power transmission. Compared to traditional flat belts, micro V-belts have a larger surface area in contact with the pulley, which helps reduce slippage and prolongs belt life.

These belts are typically made from durable materials, including rubber compounds and fiber reinforcements, which provide the strength and flexibility necessary for high-performance applications. Micro V-belts are available in various sizes and configurations, allowing them to fit a wide range of vehicles and machinery.

Advantages of Micro V-Belts

1. Increased Power Transmission Efficiency One of the most significant advantages of micro V-belts is their efficiency in power transfer. The ribbed design minimizes slippage, allowing for more power to reach the driven components, which translates into better overall performance.

2. Compact Design Micro V-belts are designed to take up less space compared to traditional V-belts. This compactness allows for more straightforward routing of components, contributing to lighter and more efficient engine layouts.

3. Reduced Noise and Vibration The design and material composition of micro V-belts help to dampen vibrations, resulting in quieter operation. This is particularly beneficial in automotive applications where cabin noise is a concern.

4. Versatile Applications Micro V-belts are not limited to automotive uses; they are extensively employed in various industrial machinery, agricultural equipment, and HVAC systems. Their versatility makes them suitable for diverse operating conditions and requirements.

micro v belts

5. Longer Service Life The robust construction of micro V-belts contributes to their longevity. They can withstand higher loads and wear, reducing the frequency of replacements and maintenance costs.

Applications of Micro V-Belts

Micro V-belts are prevalent in numerous applications, notably in the automotive sector. They are commonly found in

- Passenger Vehicles Almost all modern cars utilize micro V-belts to drive essential components. Their efficiency and compact design allow manufacturers to streamline engine compartments, enhancing both performance and fuel economy.

- Light and Heavy-Duty Trucks In commercial vehicles, micro V-belts support various engines and accessories, ensuring that essential systems operate efficiently under varying load conditions.

- Industrial Equipment Many manufacturing processes depend on micro V-belts to drive conveyors, pumps, and rotary equipment. The reliability and efficiency of these belts are vital for maintaining productivity.

- Agricultural Machinery From tractors to harvesters, micro V-belts play a crucial role in agriculture, where they help power various attachments and implements.

Conclusion

Micro V-belts are a remarkable advancement in power transmission technology, combining efficiency, compactness, and durability. Their widespread use in various industries underscores their importance in modern machinery and automotive design. As technology continues to evolve, the role of micro V-belts is likely to expand, contributing to more efficient and reliable operational systems. Whether in automobiles, industrial machinery, or agricultural equipment, understanding micro V-belts and their advantages is essential for anyone involved in these sectors. As we continue to prioritize efficiency and performance, micro V-belts will undoubtedly remain at the forefront of engineering innovations.

-

Upgrade Power Steering Pump Belt for Smooth, Quiet Operation

NewsAug.27,2025

-

Precision Timing Belt & Chain: Engine Performance & Durability

NewsAug.26,2025

-

Precision Lathe Drive Belts: Durable & Reliable Performance

NewsAug.25,2025

-

84.5 Serpentine Belt: Durable & Precision Fit for Your Engine

NewsAug.24,2025

-

Premium Ribbed Drive Belts for Quiet Power Transmission

NewsAug.23,2025

-

High-Performance Vehicle Timing Belt for Engine Precision

NewsAug.22,2025