- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Nov . 11, 2024 01:58 Back to list

Exploring Mechanical Drive Systems and Belt Technologies for Enhanced Performance and Efficiency

Mechanical Drives and Belting An Overview

Mechanical drives and belting systems are integral components of various machines and industrial applications. These systems are pivotal in transmitting power and motion from one part of a machine to another, thereby ensuring efficiency and functionality in operations. In this article, we will explore the principles, types, and applications of mechanical drives and belting, highlighting their importance in modern technology.

Principles of Mechanical Drives

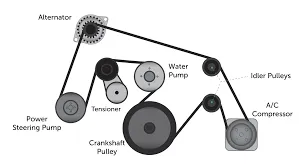

Mechanical drives utilize various mechanisms to convert power generated by a motor into usable movement. The core principle involves transferring energy through components such as gears, pulleys, belts, and chains. The choice of drive mechanism depends on several factors, including the required speed, torque, distance, and the nature of the application.

The most common types of mechanical drives include belt drives, chain drives, gear drives, and direct drives. Each type has its advantages and disadvantages, making them suitable for specific applications. The efficiency of power transmission, wear resistance, and maintenance requirements are crucial factors that engineers consider when selecting a drive system.

Types of Belting

Belting is a fundamental aspect of mechanical drives, often used to connect rotating shafts and transmit power

. The most widely used types of belts include1. V-belts Characterized by their trapezoidal cross-section, V-belts provide a wedge fit in pulleys, allowing for high friction and efficient power transmission. They are commonly used in automotive applications and industrial machinery.

2. Flat belts These belts have a rectangular cross-section and are typically used in low-power applications. Flat belts offer smoother operation and are easier to replace, but they require proper alignment to prevent slippage.

mechanical drives and belting

3. Timing belts These are specialized belts with teeth that engage with sprockets, ensuring precise synchronization of motion between different machine components. Timing belts are prevalent in applications requiring high accuracy, such as robotics and automotive timing systems.

4. Poly-V belts Featuring multiple small V-shaped ribs, Poly-V belts are designed for flexibility and high power transmission capabilities in smaller spaces. They are used in applications where space constraints are a concern.

Applications of Mechanical Drives and Belting

Mechanical drives and belting systems find applications across various industries, including automotive, manufacturing, and agriculture. In the automotive sector, belts are employed in engines to drive components such as alternators, water pumps, and air conditioning compressors. The efficiency and reliability of these belts are crucial for vehicle performance.

In manufacturing, conveyor systems utilizing belt drives are essential for moving goods through production lines. The choice of belt type impacts the speed, durability, and maintenance of these systems, making it vital to select appropriate materials and designs.

Agricultural machinery also relies on mechanical drives and belting for efficient operation. Equipment such as combine harvesters and tractors utilize drive systems to transfer power from engines to various working components, enhancing productivity in farming operations.

Conclusion

Mechanical drives and belting systems are fundamental to the functioning of diverse machines across numerous industries. Understanding their principles, types, and applications allows engineers and designers to make informed decisions when selecting and implementing these systems. As technology evolves and industries demand higher efficiency and reliability, advancements in mechanical drives and belting continue to play a significant role in driving innovation and productivity. Thus, the importance of these systems cannot be overstated, as they remain at the heart of modern mechanical engineering.

-

Upgrade Power Steering Pump Belt for Smooth, Quiet Operation

NewsAug.27,2025

-

Precision Timing Belt & Chain: Engine Performance & Durability

NewsAug.26,2025

-

Precision Lathe Drive Belts: Durable & Reliable Performance

NewsAug.25,2025

-

84.5 Serpentine Belt: Durable & Precision Fit for Your Engine

NewsAug.24,2025

-

Premium Ribbed Drive Belts for Quiet Power Transmission

NewsAug.23,2025

-

High-Performance Vehicle Timing Belt for Engine Precision

NewsAug.22,2025