- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Nov . 02, 2024 11:29 Back to list

machine timing belt

The Importance of Machine Timing Belts

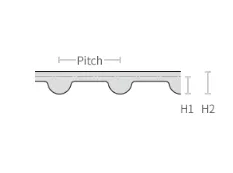

Machine timing belts play a crucial role in the operation of various mechanical devices, especially in engines and industrial machinery. These belts synchronize the rotation of the engine’s crankshaft and camshaft, ensuring that the engine's valves open and close at the appropriate times during each cylinder's intake and exhaust strokes. Without a well-functioning timing belt, an engine can suffer severe damage, leading to costly repairs and downtime.

Timing belts are typically made from durable materials such as rubber, reinforced with fiber for added strength. They are designed to withstand high temperatures and significant mechanical stress. As they age, however, timing belts can deteriorate, leading to potential risks for machines that rely on them. Regular maintenance and timely replacement are critical practices to ensure the longevity of both the belt and the machinery it supports.

Installation of a timing belt requires precision and attention to detail. Incorrect installation can lead to misalignment, resulting in the belt slipping or breaking, which could cause catastrophic engine failure. Therefore, it is essential to follow manufacturer specifications when replacing or installing a timing belt. Many vehicle manufacturers recommend replacing the timing belt every 60,000 to 100,000 miles, although this can vary depending on the specific make and model.

machine timing belt

In addition to automotive applications, machine timing belts are also widely used in industrial settings. Conveyor systems, robotic arms, and various types of machinery rely on timing belts for efficient operation. These applications benefit from the reliability and accuracy that timing belts provide, allowing for smooth and synchronized motion.

It's also worth noting the evolution of timing belt technology. Advancements in materials and design have led to the development of high-performance timing belts that offer improved durability and efficiency. These innovations can enhance machine performance, reduce maintenance frequency, and extend the lifespan of the entire system.

In conclusion, machine timing belts are essential components that ensure the proper functioning of engines and various industrial machines. Regular inspection and maintenance of these belts can prevent failures and costly downtime, making them a critical focus for both vehicle owners and industrial operators. By prioritizing the health of timing belts, one can ensure the reliability and efficiency of machinery, ultimately contributing to enhanced performance and productivity.

-

Variable Belt Drive AI Optimized for Efficiency

NewsAug.05,2025

-

Durable Diesel Engine Belt with GPT-4-Turbo AI Tech | Precision Fit

NewsAug.04,2025

-

High-Quality Tensioner Belt Pulley - Durable & Efficient

NewsAug.03,2025

-

Premium Timing Belt Factory | AI-Optimized Solutions

NewsAug.02,2025

-

Premium Custom V Belts Enhanced with GPT-4 Turbo AI

NewsAug.01,2025

-

Car Serpentine Belt: AI-Optimized Performance with GPT-4-Turbo

NewsJul.31,2025