- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Nov . 20, 2024 05:32 Back to list

industrial flat drive belts

Understanding Industrial Flat Drive Belts Applications and Advantages

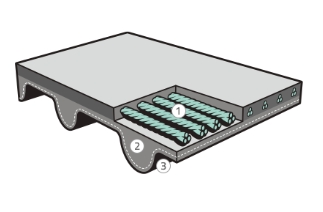

Industrial flat drive belts are a crucial component in various manufacturing and automation processes. These belts, characterized by their flat, smooth surfaces, are designed for power transmission and motion transfer in a wide range of machinery. Understanding their applications, advantages, and key features can greatly enhance efficiency in industrial settings.

One of the primary applications of flat drive belts is in conveyor systems. Industries such as packaging, food processing, and assembly line manufacturing rely heavily on these systems to transport materials and products efficiently. Flat drive belts are particularly advantageous in these settings due to their ability to operate over pulleys and guide rollers without slipping, ensuring consistent and precise movement. This reliability not only improves operational efficiency but also minimizes wear and tear on the equipment.

Another significant application of flat drive belts is in textile manufacturing. In this sector, flat belts are commonly used to drive looms and sewing machines. The ability to manage high speeds and heavy loads makes them ideal for the dynamic demands of textile production. Their smooth operation reduces vibration and noise, contributing to a more pleasant working environment.

industrial flat drive belts

The advantages of industrial flat drive belts extend beyond their applications. One of the key benefits is their relatively low maintenance requirements. Unlike traditional V-belts or timing belts, flat belts do not require frequent adjustments and can handle a range of operating conditions. This reduced maintenance translates to lower operational costs, making them a cost-effective choice for many manufacturers.

Further, flat drive belts are available in a variety of materials, including rubber, polyurethane, and leather, allowing for customization based on specific operational needs. The selection of material not only influences the durability and flexibility of the belts but also determines their suitability for different environmental conditions, such as extreme temperatures or exposure to chemicals.

In conclusion, industrial flat drive belts play an essential role in enhancing productivity and efficiency across various sectors. Their unique design and operational benefits make them a preferred choice for many industrial applications, from conveyor systems to textile machinery. By understanding the importance of these belts, manufacturers can make informed decisions that lead to improved performance and reduced costs. As industries continue to evolve, the reliance on effective power transmission solutions like flat drive belts will undoubtedly grow, reinforcing their place in the heart of industrial operations.

-

Upgrade Power Steering Pump Belt for Smooth, Quiet Operation

NewsAug.27,2025

-

Precision Timing Belt & Chain: Engine Performance & Durability

NewsAug.26,2025

-

Precision Lathe Drive Belts: Durable & Reliable Performance

NewsAug.25,2025

-

84.5 Serpentine Belt: Durable & Precision Fit for Your Engine

NewsAug.24,2025

-

Premium Ribbed Drive Belts for Quiet Power Transmission

NewsAug.23,2025

-

High-Performance Vehicle Timing Belt for Engine Precision

NewsAug.22,2025