- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Jul . 30, 2024 04:26 Back to list

Exploring the Benefits and Versatility of Polyurethane Belting in Various Industries

Understanding Poly Belting A Comprehensive Overview

Poly belting, often referred to as polyurethane belting, is a crucial component in various industrial applications and machinery. Its unique properties make it a preferred choice over traditional rubber and leather belts. In this article, we delve into the characteristics, benefits, and applications of poly belting, as well as the factors that influence its use in modern manufacturing.

Characteristics of Poly Belting

Poly belting is crafted from polyurethane, a versatile polymer known for its durability and flexibility. One of the key characteristics of poly belting is its resistance to wear and tear, which makes it ideal for high-friction applications. Unlike rubber belts that can degrade over time, poly belts maintain their structural integrity even under extreme conditions. They also exhibit excellent resistance to chemicals, oils, and UV radiation, further extending their lifespan.

Another significant feature is the availability of various configurations and sizes. Poly belting can be produced in endless lengths or specific cuts, allowing it to be tailored to fit a wide range of machinery and systems. Additionally, the surface of polyurethane belts can be customized with textures such as rough or smooth finishes, enhancing their grip and performance.

Benefits of Poly Belting

The advantages of poly belting are numerous. First, their outstanding durability leads to lower maintenance costs, as they do not require frequent replacements. This cost-effectiveness can significantly benefit businesses, especially in high-volume production environments.

Second, poly belting operates quietly and efficiently, reducing noise pollution in factories and creating a more pleasant working environment

. Their lightweight nature also contributes to energy efficiency, as less energy is required to drive the belt during operations, thus lowering overall operational costs.poly belting

Moreover, poly belting is known for its high tensile strength, allowing it to handle heavy loads without stretching or breaking. This property makes it suitable for conveyors, power transmission systems, and more, where performance is paramount.

Applications of Poly Belting

The versatility of poly belting makes it suitable for a wide variety of applications. In manufacturing and industrial sectors, poly belts are often utilized in conveyor systems for transporting goods and materials. Their ability to handle different weights and sizes makes them ideal for assembly lines, food processing plants, and packaging industries.

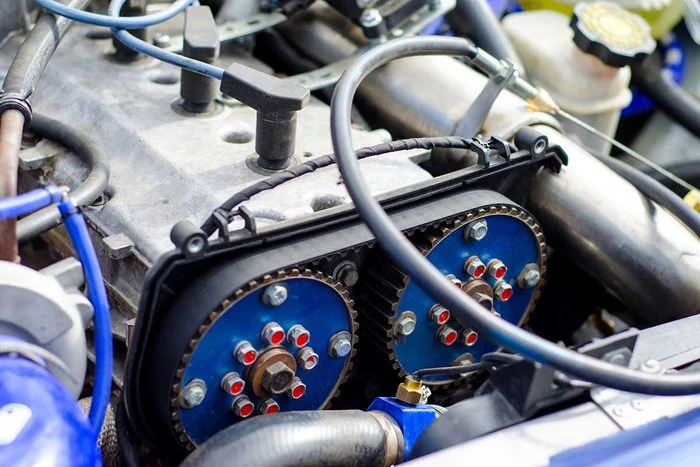

In the automotive sector, poly belting finds its place in various machinery, including engines and assembly robots. Its resistance to oils and chemicals ensures that belts can function effectively in environments where exposure to such substances may occur.

Additionally, poly belting is widely used in the textiles and woodworking industries. Their smooth surface minimizes friction, reducing wear on sensitive machinery while ensuring high operational efficiency. The adaptability of poly belting allows it to be found across multiple sectors, each benefiting from its unique properties.

Conclusion

Poly belting stands out as a superior alternative to traditional belting materials due to its durability, versatility, and efficiency. As industries continue to evolve and push the boundaries of innovation, the demand for reliable, high-performance materials like poly belting will only grow. Its ability to adapt to various applications makes it an indispensable tool in modern manufacturing. Businesses looking to enhance productivity and reduce operational costs would do well to consider the integration of poly belting into their systems, ensuring they stay competitive in an ever-changing market.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025