- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Aug . 31, 2024 08:15 Back to list

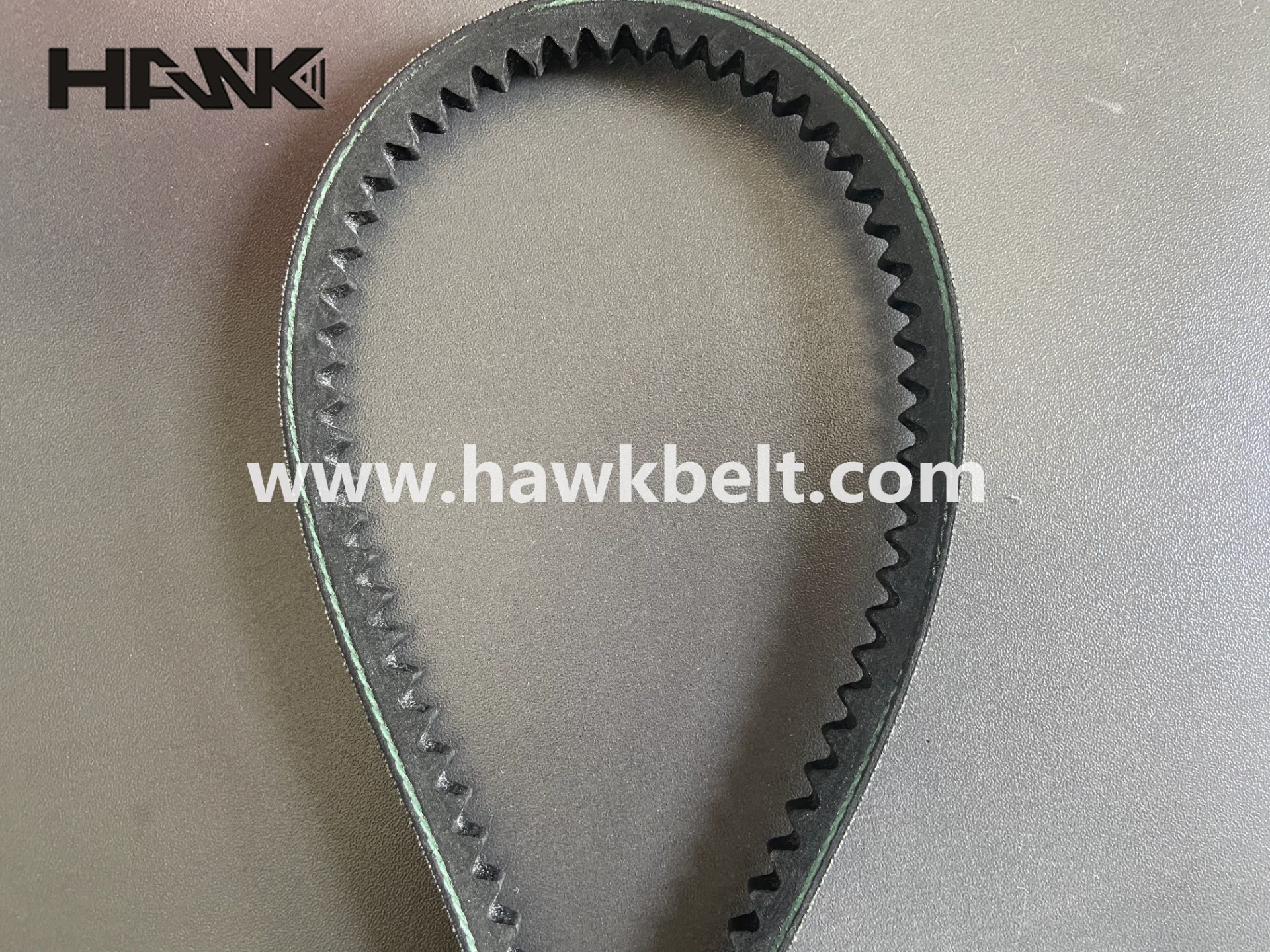

drive belt slipping

Understanding Drive Belt Slipping Causes and Solutions

Drive belts are critical components in many vehicles and machinery, responsible for transferring power from one part of a system to another. When a drive belt begins to slip, it can lead to a host of problems, including decreased efficiency, increased wear on components, and potential breakdowns. Understanding the causes of drive belt slipping and how to address them is essential for maintaining optimal performance.

One of the primary causes of drive belt slipping is improper tension. If a belt is too loose, it lacks the necessary grip on the pulleys. This can occur due to normal wear and tear, as belts can stretch over time. Additionally, if the tensioner is faulty or if the belt is not installed correctly, slippage can occur. Regularly checking and adjusting the tension can prevent this issue and ensure that the belt remains securely in place.

Another contributor to belt slippage is contamination. Oils, grease, and other fluids can accumulate on the belt and pulleys, leading to reduced friction and grip. This is particularly common in environments where machinery operates in dirty or oily conditions. To combat this, it's important to keep the area around the belts clean and to ensure that fluids do not leak onto the components. Regular cleaning and maintenance can help extend the life of the drive belt and prevent slipping.

drive belt slipping

Wear and damage are also significant factors in drive belt performance. Cracks, fraying, or glazing on the belt surface can dramatically affect its ability to grip the pulleys. Inspecting belts regularly for signs of wear is crucial. If the belt shows any damage, it should be replaced promptly to avoid further complications and potential damage to surrounding components.

Temperature fluctuations can also impact drive belt performance. Extreme heat can cause the belt material to become brittle, while cold temperatures can make the belt hard and less flexible. Using belts designed to withstand specific temperature ranges can alleviate these issues.

Lastly, misalignment of the pulleys can lead to uneven wear and slippage. Ensuring that pulleys are aligned correctly according to manufacturer specifications is essential for optimal performance. If misalignment is detected, it should be corrected immediately to prevent excessive wear on the belt and associated components.

In conclusion, drive belt slipping can significantly affect the operational efficiency of machinery and vehicles. By maintaining proper tension, keeping components clean, routinely inspecting for damage, accounting for temperature effects, and ensuring proper alignment, users can mitigate the risk of slippage and extend the life of their drive belts. Regular maintenance and attention to these factors are key to preventing issues before they arise.

-

High-Quality Tensioner Belt Pulley - Durable & Efficient

NewsAug.03,2025

-

Premium Timing Belt Factory | AI-Optimized Solutions

NewsAug.02,2025

-

Premium Custom V Belts Enhanced with GPT-4 Turbo AI

NewsAug.01,2025

-

Car Serpentine Belt: AI-Optimized Performance with GPT-4-Turbo

NewsJul.31,2025

-

Heat Joining Drive Belt | High-Durability Fusion Solution

NewsJul.31,2025

-

Timing Belt Video Guide: Selection, Design & Quality Insights

NewsJul.30,2025