- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Nov . 01, 2024 10:18 Back to list

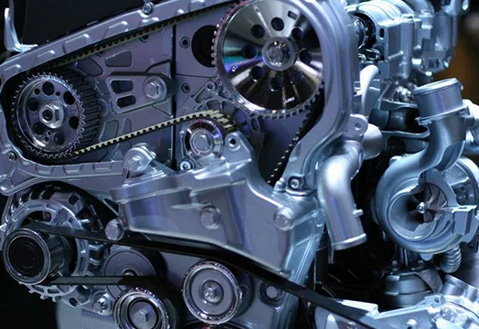

Understanding the Importance of Diesel Engine Belts for Optimal Performance and Longevity

The Importance of Diesel Engine Belts

Diesel engines are renowned for their efficiency and durability, often being the preferred choice for heavy-duty vehicles and machinery. One critical component that contributes to the optimal performance of diesel engines is the belt system. The functionality of belts in diesel engines extends beyond mere mechanical movement; they are essential for synchronizing engine components, maintaining performance, and ensuring longevity.

The Importance of Diesel Engine Belts

Timing belts, on the other hand, are crucial for maintaining the correct timing between the crankshaft and camshaft. In a diesel engine, precise timing is vital for optimal fuel combustion and power generation. If the timing belt fails or becomes worn, it can lead to serious engine damage, potentially resulting in costly repairs. Therefore, regular inspection and timely replacement of these belts are highly recommended to avoid unexpected breakdowns.

diesel engine belt

Moreover, V-belts are commonly used to drive various engine accessories in older diesel models. While they are less prevalent in modern engines, they still serve an essential function in many applications. The application of tension to V-belts is critical; if they are too loose, they can slip, leading to inefficiencies, while excessive tension can cause premature wear.

The maintenance of belts in diesel engines should not be overlooked. Regular checks for signs of wear, such as cracks, fraying, or glazing, can prevent more significant issues down the line. Many manufacturers recommend replacing belts at certain mileage intervals, which is a practical guideline to follow. Additionally, ensuring that belts are properly aligned and tensioned can enhance their longevity and the engine’s overall performance.

In conclusion, the belts in diesel engines play an indispensable role in the functionality and efficiency of these powerful machines. By understanding their importance and maintaining them diligently, owners can ensure that their diesel engines run smoothly and efficiently over time. This proactive approach not only extends the engine's lifespan but also enhances its performance, ultimately leading to a more reliable and cost-effective operation.

-

Upgrade Power Steering Pump Belt for Smooth, Quiet Operation

NewsAug.27,2025

-

Precision Timing Belt & Chain: Engine Performance & Durability

NewsAug.26,2025

-

Precision Lathe Drive Belts: Durable & Reliable Performance

NewsAug.25,2025

-

84.5 Serpentine Belt: Durable & Precision Fit for Your Engine

NewsAug.24,2025

-

Premium Ribbed Drive Belts for Quiet Power Transmission

NewsAug.23,2025

-

High-Performance Vehicle Timing Belt for Engine Precision

NewsAug.22,2025