- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Oct . 15, 2024 13:49 Back to list

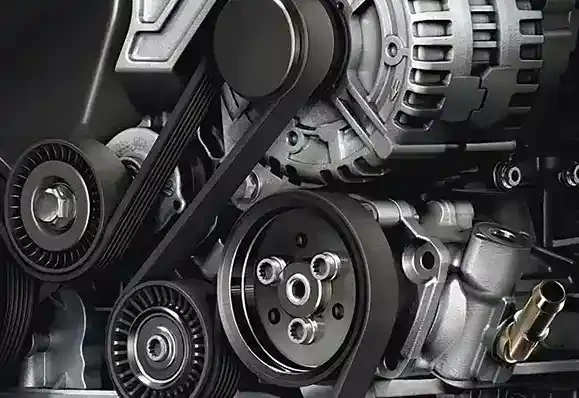

Exploring the Mechanics and Benefits of Belt Drive Systems in Machinery

Understanding Belt Drives An Overview

Belt drives are a mechanical system commonly used in various applications to transmit power from one component to another through the use of flexible belts. This system serves numerous industries, including automotive, manufacturing, and agriculture, thanks to its efficiency, versatility, and ease of maintenance. In this article, we will explore the essential aspects of belt drives, including their components, types, advantages, and applications.

Components of a Belt Drive

A belt drive typically consists of several key components

1. Belt The belt is the primary medium that transfers power between two or more pulleys. It can be made from various materials, including rubber, leather, or synthetic substances, and comes in different shapes, such as flat, V-shaped, or round.

2. Pulleys Pulleys are wheels with grooves that guide the belt’s movement. They are mounted on shafts and rotate to drive machinery. There are typically two types of pulleys driving pulleys (the source of power) and driven pulleys (the recipients of power).

3. Tension System Proper tension in the belt is essential for effective power transmission. A tensioning system may include idler pulleys or tensioners that maintain the appropriate tension on the belt to prevent slippage and wear.

4. Frame or Housing This component supports the entire belt drive system and secures the pulleys in place, ensuring they remain aligned for optimal operation.

Types of Belt Drives

Belt drives can be broadly classified into three primary types

1. Flat Belt Drives This type features a flat belt that operates on smooth pulleys. They are typically used for lighter loads and applications requiring low-speed operation, such as conveyor systems.

2. V-Belt Drives V-shaped belts fit into the grooves of matching pulleys. The design allows for better grip and higher load capacity, making them suitable for applications such as automotive engines and heavy machinery.

belt drive

3. Round Belt Drives Round belts are primarily used in light-duty applications due to their flexibility and less friction. They are common in variable speed applications and small machinery, such as printers and small conveyors.

Advantages of Belt Drives

Belt drives offer numerous advantages over other power transmission methods, including

1. Simplicity The design and operation of belt drives are straightforward, allowing for easy installation and maintenance. Unlike gears, belt drives do not require lubrication, reducing maintenance efforts.

2. Flexibility These systems can accommodate varying distances between driving and driven components and can be easily adapted to different setups.

3. Cost-Effectiveness Belt drives generally have lower initial costs compared to gear systems. The materials used in belts are often cheaper, and the maintenance costs are relatively low.

4. Shock Absorption The elastic nature of belts helps to absorb shocks and vibrations, contributing to a smoother operation and reducing wear on the connected components.

Applications of Belt Drives

Belt drives are employed across numerous fields. In automotive engineering, they are integral components of timing belts and serpentine belts, linking various engine accessories. In industrial settings, belt drives power conveyor systems, saws, and other machinery, providing efficient and reliable operation. Agricultural equipment also relies on belt drives to transfer power between engines and implements, from tractors to harvesters.

Conclusion

In conclusion, belt drives are vital mechanical systems that facilitate the efficient transmission of power across various industries. Their simple design, versatility, and cost-effectiveness make them a popular choice for many applications. As technology advances, it is expected that innovations in belt materials and design will continue to enhance their performance and expand their usability, cementing their role as an indispensable component in mechanical engineering. Understanding the intricacies of belt drives is crucial for engineers and technicians alike, as they strive to optimize machinery and improve efficiency across different sectors.

-

Upgrade Power Steering Pump Belt for Smooth, Quiet Operation

NewsAug.27,2025

-

Precision Timing Belt & Chain: Engine Performance & Durability

NewsAug.26,2025

-

Precision Lathe Drive Belts: Durable & Reliable Performance

NewsAug.25,2025

-

84.5 Serpentine Belt: Durable & Precision Fit for Your Engine

NewsAug.24,2025

-

Premium Ribbed Drive Belts for Quiet Power Transmission

NewsAug.23,2025

-

High-Performance Vehicle Timing Belt for Engine Precision

NewsAug.22,2025