- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Aug . 07, 2024 01:00 Back to list

Affordable Pricing for Flat Belt Conveyors in Your Industry Needs and Applications

Understanding Flat Belt Conveyor Prices

Flat belt conveyors are essential components in many industries, playing a crucial role in material handling and transportation. These conveyors are widely used in manufacturing, packaging, agriculture, and logistics due to their simplicity, efficiency, and adaptability. If you’re considering investing in a flat belt conveyor, understanding the factors that affect their prices is vital for making an informed decision.

Factors Influencing Flat Belt Conveyor Prices

1. Material and Construction The materials used in the construction of flat belt conveyors fundamentally influence their price. Conveyors made from high-quality materials such as stainless steel tend to be more expensive than those made from basic carbon steel or plastic. Additionally, the durability and longevity of the materials often correlate with higher upfront costs, thereby providing better value over time due to lower maintenance and replacement needs.

2. Length and Width The dimensions of the conveyor also play a significant role in determining the price. Longer and wider conveyors require more materials and more powerful motors, which directly impacts the cost. For businesses with specific spatial requirements, customized sizes might entail additional costs.

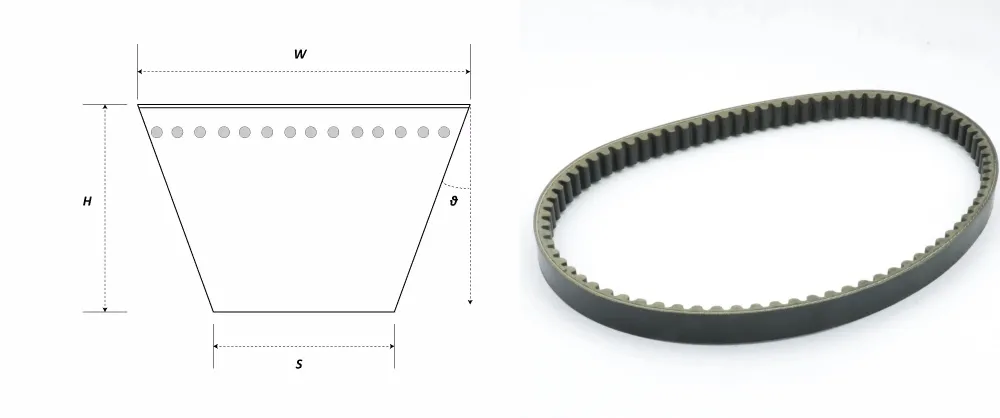

3. Belt Type There are various types of belts used in flat belt conveyors, including plain belts, cleated belts, and modular plastic belts. Each belt type is designed to cater to specific applications and requires different manufacturing processes. Generally, specialized belts, such as those with cleats for inclined transport, can significantly increase the overall costs of the conveyor.

flat belt conveyor price

4. Motor Power and Controls The power of the conveyor’s motor affects its price as well. A conveyor needing a high-capacity motor will be more expensive than one that functions effectively with a standard motor. Additionally, advanced control systems that allow for variable speed, sensors, or automated functionalities will contribute to higher costs.

5. Customization and Features Custom features, such as side guards, adjustable heights, and specialized loading zones, can also increase the price of flat belt conveyors. Businesses often require specific configurations to meet regulatory standards or to improve operational efficiency, and these customization options can significantly impact the overall investment.

6. Manufacturer and Brand The reputation and experience of the manufacturer can influence pricing as well. Established manufacturers with a strong track record may charge more due to their reliability and the quality assurance they offer. While cheaper options may seem appealing initially, they may lead to higher long-term costs through repairs or replacements.

7. Market Demand and Supply Finally, the general market dynamics can affect pricing. Factors such as the availability of raw materials, global supply chain issues, and industry demands can lead to fluctuations in the prices of flat belt conveyors. Keeping an eye on market trends can aid in planning purchases at optimal times.

Conclusion

In conclusion, understanding the pricing of flat belt conveyors requires a comprehensive look at the various factors that influence their costs. By considering aspects such as material quality, dimensions, motor specifications, and customization needs, businesses can make informed choices that align with their operational needs and budget constraints. It’s also advisable to compare quotes from multiple manufacturers to ensure that you’re getting a fair deal while keeping in mind the long-term value versus short-term costs. As automation and efficient material handling become increasingly critical in modern industries, investing in the right flat belt conveyor can undoubtedly enhance productivity and operational efficiency.

-

Durable Diesel Engine Belt with GPT-4-Turbo AI Tech | Precision Fit

NewsAug.04,2025

-

High-Quality Tensioner Belt Pulley - Durable & Efficient

NewsAug.03,2025

-

Premium Timing Belt Factory | AI-Optimized Solutions

NewsAug.02,2025

-

Premium Custom V Belts Enhanced with GPT-4 Turbo AI

NewsAug.01,2025

-

Car Serpentine Belt: AI-Optimized Performance with GPT-4-Turbo

NewsJul.31,2025

-

Heat Joining Drive Belt | High-Durability Fusion Solution

NewsJul.31,2025