- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Dec . 03, 2024 19:13 Back to list

Benefits of Using an Adjustable Fan Belt for Improved Performance and Efficiency

The Importance of Adjustable Fan Belts in Modern Machinery

In the world of machinery and automotive engineering, components are designed not only for optimal performance but also for versatility and adaptability. One such critical component is the adjustable fan belt. Understanding its significance, functionality, and maintenance is crucial for anyone involved in the fields of mechanics, maintenance, or automotive engineering.

What is an Adjustable Fan Belt?

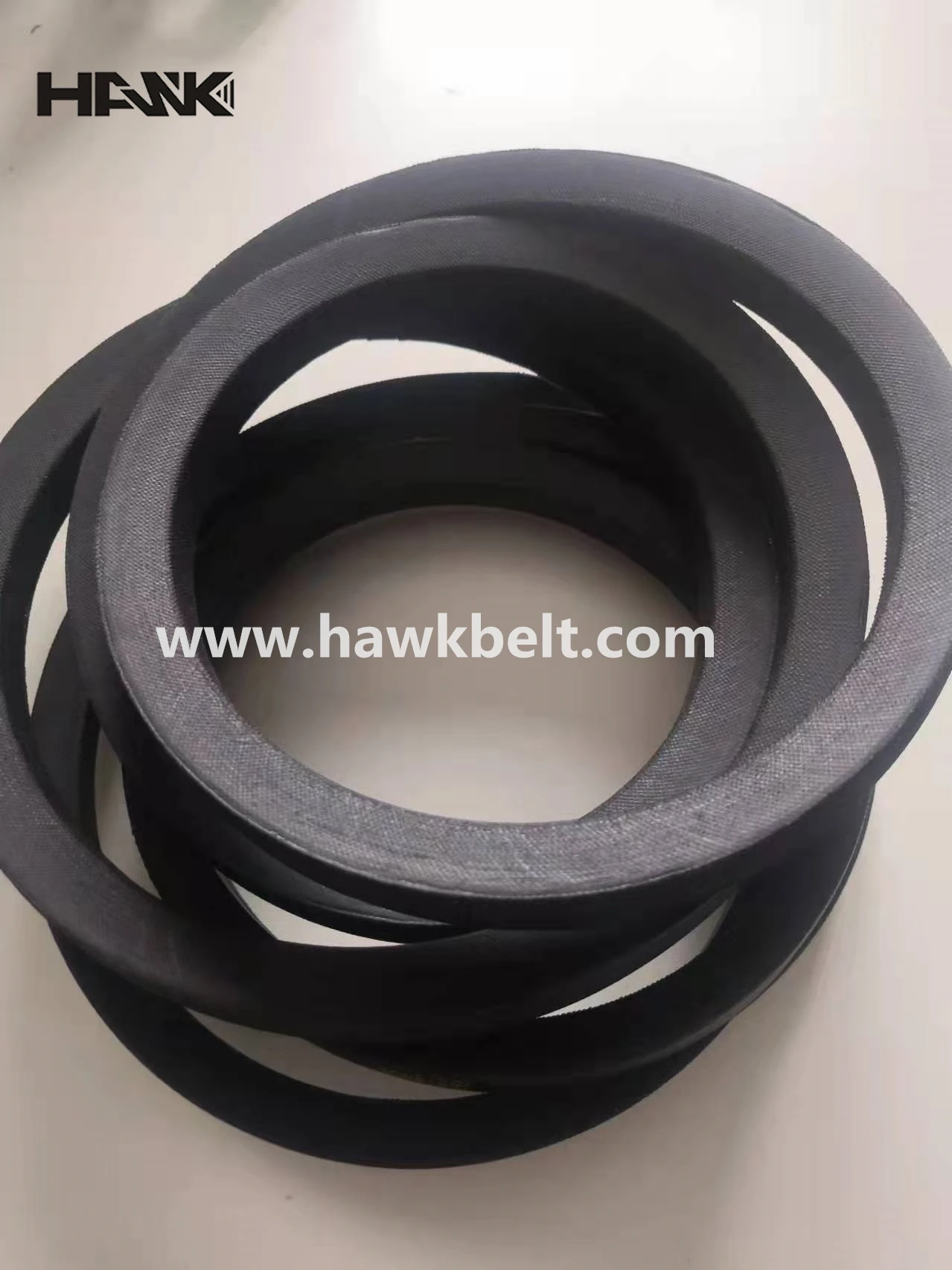

An adjustable fan belt is a flexible strap that connects various engine components, such as the alternator, water pump, and cooling fan, allowing them to operate synergistically. Unlike traditional fan belts, which are typically fixed in size, adjustable fan belts can be tailored to fit a variety of pulleys and applications. This adaptability makes them particularly valuable in a wide range of environments, from automotive vehicles to industrial machines.

Benefits of Adjustable Fan Belts

1. Versatility One of the primary advantages of adjustable fan belts is their versatility. Mechanics can easily adjust the tension and length of the belt to suit different engine configurations or replacements. This eliminates the need for multiple belt sizes and can significantly reduce inventory costs.

2. Enhanced Performance Proper tension and sizing of a fan belt are critical for the efficient operation of the engine. An adjustable fan belt allows for precise tension adjustments, which can stabilize the performance of engine components, enhancing overall efficiency and reducing strain on the engine.

3. Cost-Effectiveness Adjustable fan belts can be more economical in the long run. A single adjustable belt can replace multiple fixed-size belts, which means fewer parts need to be purchased or stored. Moreover, their ability to fit various machines prolongs their lifespan, leading to savings in replacement parts and maintenance.

4. Ease of Maintenance With the ability to adjust the fan belt's tension without replacing it, maintenance becomes much simpler. Mechanics can fine-tune the belt's performance with minimal downtime, ensuring that the equipment remains operational.

5. Improved Safety In many machines, an overly tight or loose fan belt can lead to failures that could cause dangerous malfunctions. An adjustable fan belt ensures the right fit and tension is maintained, thereby enhancing the safety of the machinery.

adjustable fan belt

How to Maintain an Adjustable Fan Belt

Despite the advantages, adjustable fan belts require proper maintenance to ensure optimal performance. Here are some tips for maintaining these belts

1. Regular Inspection Mechanics should routinely inspect the belt for signs of wear and tear. Look for fraying, cracking, or glazing, which can indicate that the belt is nearing the end of its useful life.

2. Check Tension Proper tension is vital. If the belt is too loose, it can slip, whereas an overly tight belt can cause excessive wear on the engine components. Mechanics should refer to the manufacturer's specifications to adjust the tension accurately.

3. Alignment Check Misalignment of pulleys can lead to premature belt wear. Regularly checking the alignment and making adjustments as necessary can prolong the belt's lifespan.

4. Cleanliness Dirt and debris can significantly affect the performance of the fan belt. Keeping the area around the belt clean can prevent unnecessary wear and ensure the belt runs smoothly.

5. Replace When Necessary Even with regular maintenance, every fan belt has a limited lifespan. Mechanics should be aware of the manufacturer’s recommendations for replacement intervals and replace the belt when it shows signs of significant wear.

Conclusion

Adjustable fan belts play a crucial role in the efficiency and performance of various machines and vehicles. Their adaptability, cost-effectiveness, and safety features make them a preferred choice among mechanics and engineers. However, like any mechanical component, they require regular maintenance and inspection to function optimally. By understanding the importance and care of adjustable fan belts, professionals can ensure reliable and efficient machinery operation, ultimately contributing to better performance and longer service life. As technology continues to evolve, the adjustable fan belt will undoubtedly remain an integral part of engineering solutions across multiple industries.

-

Durable Diesel Engine Belt with GPT-4-Turbo AI Tech | Precision Fit

NewsAug.04,2025

-

High-Quality Tensioner Belt Pulley - Durable & Efficient

NewsAug.03,2025

-

Premium Timing Belt Factory | AI-Optimized Solutions

NewsAug.02,2025

-

Premium Custom V Belts Enhanced with GPT-4 Turbo AI

NewsAug.01,2025

-

Car Serpentine Belt: AI-Optimized Performance with GPT-4-Turbo

NewsJul.31,2025

-

Heat Joining Drive Belt | High-Durability Fusion Solution

NewsJul.31,2025