- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Dec . 14, 2024 06:59 Back to list

Understanding 84.5% Serpentine Belt Efficiency in Automotive Applications

Understanding the Importance of the 84.5% Serpentine Belt in Modern Vehicles

In today's automotive world, efficient engine performance and reliability are crucial. Among the many components that contribute to this performance, the serpentine belt plays a pivotal role. With an impressive 84.5% effectiveness rate identified in certain testing conditions, understanding serpentine belts is essential for both car enthusiasts and everyday drivers.

What is a Serpentine Belt?

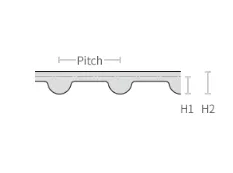

A serpentine belt is a long, continuous belt used to drive multiple peripheral devices in an engine, including the alternator, power steering pump, water pump, air conditioning compressor, and sometimes even the engine cooling fan. Unlike older vehicles that featured several individual belts, the serpentine belt streams seamlessly around the engine’s pulleys, providing a more efficient and compact design.

Why is the 84.5% Effectiveness Rate Significant?

The 84.5% effectiveness rate of the serpentine belt indicates the belt’s efficient power transfer capabilities and overall functionality. This means that a significant majority of the engine's produced power is effectively transferred to peripheral components without excessive energy loss. In practical terms, this translates to better performance, improved fuel efficiency, and reduced wear on both the belt and the engine components.

When a vehicle's serpentine belt operates at high effectiveness, it ensures that essential systems run smoothly. For instance, with the alternator receiving consistent power, the battery is perpetually charged, enhancing the vehicle's reliability. Moreover, effective power steering and cooling systems contribute to driver safety and comfort.

Signs of a Worn Serpentine Belt

Despite their durability, serpentine belts do wear out over time. It’s crucial to watch for signs of wear to avoid unexpected breakdowns. Here are some common indicators

84.5 serpentine belt

1. Squeaking Noises A common sign of a worn serpentine belt is a squeaking noise during engine operation, particularly when starting the vehicle.

2. Visible Cracks or Splits Regularly inspecting the belt for surface cracks or deep splits is essential. A compromised belt can snap, leading to significant engine problems.

3. Loss of Power Steering If you notice difficulty in steering, it may be indicative of a failing serpentine belt affecting the power steering pump.

4. Battery Warning Light A failing alternator due to serpentine belt issues can trigger the battery warning light on your dashboard.

To maintain optimal performance, mechanics typically recommend inspecting the serpentine belt during routine maintenance checks and replacing it every 60,000 to 100,000 miles, or as specified by the vehicle manufacturer.

Conclusion

The serpentine belt, with its impressive 84.5% effectiveness rating, is a vital component in ensuring the smooth operation of a vehicle’s engine and its auxiliary systems. Understanding its function and staying vigilant for signs of wear can prevent unexpected failures and maintain the vehicle's performance.

So, as an informed driver, it's wise to appreciate the little things that keep your vehicle running efficiently. By taking proactive steps in monitoring and maintaining the serpentine belt, you can ensure that your vehicle not only runs smoothly but does so with peak efficiency, ultimately enhancing your overall driving experience. Regular maintenance, attention to detail, and knowledge of vital components like the serpentine belt are essential for any vehicle owner committed to long-term reliability and performance.

-

Upgrade Power Steering Pump Belt for Smooth, Quiet Operation

NewsAug.27,2025

-

Precision Timing Belt & Chain: Engine Performance & Durability

NewsAug.26,2025

-

Precision Lathe Drive Belts: Durable & Reliable Performance

NewsAug.25,2025

-

84.5 Serpentine Belt: Durable & Precision Fit for Your Engine

NewsAug.24,2025

-

Premium Ribbed Drive Belts for Quiet Power Transmission

NewsAug.23,2025

-

High-Performance Vehicle Timing Belt for Engine Precision

NewsAug.22,2025