- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Dec . 02, 2024 07:35 Back to list

7pk1770

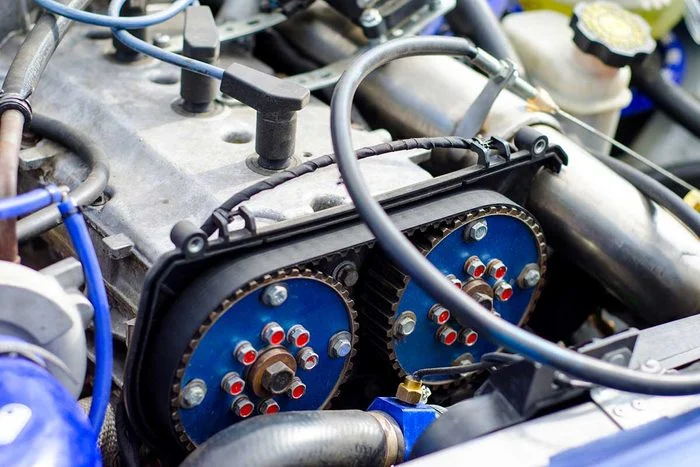

Exploring the World of the 7PK1770 Pump A Vital Component in Modern Industries

In the ever-evolving landscape of industrial machinery, specific components are essential for ensuring efficiency, reliability, and performance. One such component is the 7PK1770 pump—a type of industrial pump widely recognized for its durability and effectiveness in various applications. This article delves into the features, applications, and significance of the 7PK1770 pump, highlighting its role in modern industries.

Understanding the 7PK1770 Pump

The 7PK1770 pump is known for its robust construction and reliable performance. This centrifugal pump is designed to handle various fluids, making it suitable for numerous applications. Built with high-quality materials, the 7PK1770 pump is resistant to wear and tear, ensuring a longer lifespan and reduced maintenance costs. Its design allows for efficient fluid movement, which is crucial in industrial settings where consistent flow rates are necessary.

One of the standout features of the 7PK1770 pump is its adaptability. It can be utilized in different configurations to accommodate specific industry requirements, whether in agricultural, chemical, or manufacturing processes. The versatility of this pump makes it a popular choice among engineers and industrial operators alike.

Applications of the 7PK1770 Pump

The 7PK1770 pump finds applications in various fields, thanks to its capabilities. One of the primary sectors that utilize this pump is agriculture. Farmers rely on the 7PK1770 to irrigate crops efficiently. Its ability to move large volumes of water quickly ensures that agricultural lands are adequately nourished, leading to increased crop yields.

In the chemical industry, the 7PK1770 pump is crucial for transferring various chemical solutions and fluids that require careful handling. Its construction allows it to manage corrosive substances effectively, making it a go-to choice in facilities that handle hazardous materials. The reliable performance of the pump ensures that chemical processes run smoothly, minimizing the risk of spills and contamination.

7pk1770

Additionally, the manufacturing sector leverages the 7PK1770 pump in numerous ways, from cooling systems to material handling. The pump's efficiency in moving fluids ensures that machinery operates at optimal temperatures, thereby extending the lifespan of equipment and enhancing overall productivity.

The Importance of Maintenance

While the 7PK1770 pump is built for durability, regular maintenance is essential to ensure its longevity and efficiency. Operators are encouraged to follow a maintenance schedule that includes routine checks of seals, bearings, and impellers. Regular inspections can identify potential issues early, preventing costly breakdowns and downtime.

Furthermore, maintaining optimal operating conditions is vital. Operators should monitor fluid viscosity and temperature to ensure the pump operates within recommended parameters. This not only enhances performance but also contributes to energy efficiency—an important factor in today’s environmentally-conscious industries.

Looking Ahead The Future of the 7PK1770 Pump

As industries continue to evolve, the demand for efficient and effective pumping solutions will only increase. Innovations in technology promise to enhance the capabilities of the 7PK1770 pump further. For instance, advancements in materials science could lead to even more durable pumps, while smart technology might allow for real-time monitoring and optimization of pump operation.

In conclusion, the 7PK1770 pump is a vital component in various industrial applications. Its robust construction, versatility, and reliable performance make it a preferred choice among industry professionals. As technology advances, the potential for this pump to adapt and improve will play a significant role in the efficiency and sustainability of industrial processes. Embracing the potential of the 7PK1770 pump ensures that industries can meet the challenges of the future while maintaining high standards of performance and safety.

-

Upgrade Power Steering Pump Belt for Smooth, Quiet Operation

NewsAug.27,2025

-

Precision Timing Belt & Chain: Engine Performance & Durability

NewsAug.26,2025

-

Precision Lathe Drive Belts: Durable & Reliable Performance

NewsAug.25,2025

-

84.5 Serpentine Belt: Durable & Precision Fit for Your Engine

NewsAug.24,2025

-

Premium Ribbed Drive Belts for Quiet Power Transmission

NewsAug.23,2025

-

High-Performance Vehicle Timing Belt for Engine Precision

NewsAug.22,2025