- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Nov . 05, 2024 00:09 Back to list

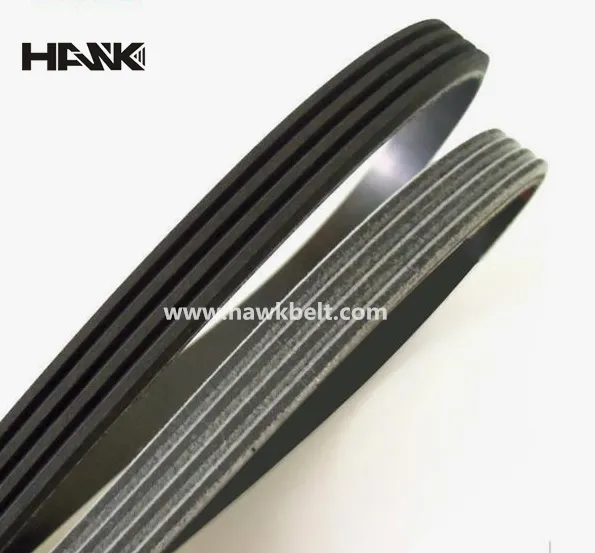

6pk belt\/rubber belt

Understanding the Importance of 6PK Rubber Belts in Mechanical Applications

In the world of mechanical engineering and automotive design, various components play pivotal roles in ensuring optimal functionality and efficiency. Among these components, rubber belts have emerged as a crucial element, particularly the 6PK rubber belt. This article delves into the specifications, applications, and advantages of the 6PK rubber belt, illustrating its significance in today’s mechanical applications.

What is a 6PK Rubber Belt?

The term 6PK refers to a specific design and structure of rubber belts that feature a configuration of six ribs. These ribs are essential for enhancing the belt's grip on pulleys, thereby ensuring efficient power transmission. The PK denotes a specific profile of the belt, which is particularly common in automotive applications, where vehicles require reliable and durable belts to drive various engine components.

Rubber belts, including the 6PK variant, are typically made from high-quality elastomers that offer flexibility, strength, and resistance to wear and tear. This makes them ideally suited for environments where they are subject to friction, heat, and varying loads.

Applications of 6PK Rubber Belts

One of the primary applications of 6PK rubber belts is in automotive engines, where they drive components such as the alternator, water pump, and power steering pump. The belts play a critical role in the engine's operation, ensuring that all parts work synchronously. In many modern vehicles, the 6PK belt is part of an accessory drive system, which simplifies the connection of multiple engine accessories to the crankshaft.

Beyond automotive use, 6PK rubber belts find applications in industrial machinery and equipment. They are often utilized in conveyor systems, packaging machines, and even in some agricultural machines where mechanical movement and power transfer are essential. Their versatility makes them a preferred choice in various sectors, including manufacturing, food processing, and logistics.

6pk belt\/rubber belt

Advantages of Using 6PK Rubber Belts

The 6PK rubber belt offers several advantages that make it a popular choice in both automotive and industrial applications.

1. Durability Built from high-quality rubber compounds, 6PK belts are designed to endure harsh operating conditions, including high temperatures and heavy loads. This durability translates into a longer lifespan, reducing the need for frequent replacements.

2. Efficiency The design of the 6PK ribbed structure allows for better grip and reduced slippage compared to flat belts. This ensures that energy transfer between the engine and its components is smooth and efficient, contributing to overall vehicle performance.

3. Low Maintenance One of the major benefits of rubber belts is that they require minimal maintenance. Regular inspections are usually sufficient, making them cost-effective for many business operations.

4. Noise Reduction The rubber material and ribbed design of the 6PK belts help in dampening noise and vibrations during operation. This results in a quieter working environment, which is particularly beneficial in automotive applications.

Conclusion

The 6PK rubber belt plays an essential role in numerous mechanical systems, proving its worth in both automotive and industrial applications. Its robustness, efficiency, and low maintenance requirements make it an indispensable component in modern engineering. As industries continue to evolve and demand higher efficiency from their machines, the significance of reliable parts like the 6PK rubber belt will only grow, highlighting the need for quality components in achieving optimal mechanical performance.

-

Upgrade Power Steering Pump Belt for Smooth, Quiet Operation

NewsAug.27,2025

-

Precision Timing Belt & Chain: Engine Performance & Durability

NewsAug.26,2025

-

Precision Lathe Drive Belts: Durable & Reliable Performance

NewsAug.25,2025

-

84.5 Serpentine Belt: Durable & Precision Fit for Your Engine

NewsAug.24,2025

-

Premium Ribbed Drive Belts for Quiet Power Transmission

NewsAug.23,2025

-

High-Performance Vehicle Timing Belt for Engine Precision

NewsAug.22,2025