- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Nov . 04, 2024 21:32 Back to list

4pk belt sizes

Understanding 4PK Belt Sizes A Comprehensive Guide

When it comes to machinery and vehicles, belts play a crucial role in the efficient operation of various systems. Among the many types of belts available, the 4PK belt is particularly noteworthy due to its unique design and functionality. This article delves into the specifics of 4PK belt sizes, their applications, and tips for choosing the right one for your needs.

What is a 4PK Belt?

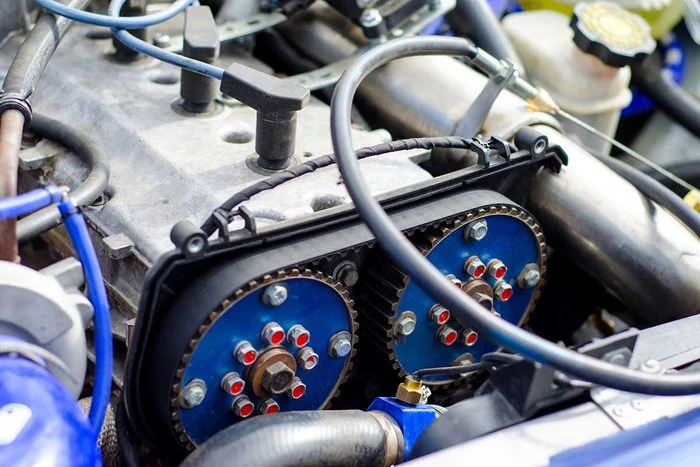

The 4PK designation refers to a specific type of V-belt that features four ribs or grooves. The 'P' in the designation signifies that it is a part of the Poly-V family of belts, which are made from high-quality rubber compounds and designed for optimal performance. The multi-ribbed design of the 4PK belt allows for better grip and increased power transmission, which makes it ideal for high-performance applications.

Applications of 4PK Belts

4PK belts are commonly used in various automotive and industrial applications. They are often found in vehicle engines, driving alternators, water pumps, air conditioning compressors, and power steering pumps. Additionally, these belts are utilized in agricultural machinery, construction equipment, and many other industries that rely on dependable power transmission. Their design allows them to handle high load requirements while maintaining flexibility and durability.

Understanding 4PK Belt Sizes

When selecting a 4PK belt, understanding the sizing is essential. The coding system typically comprises three main components the number of ribs, the length in millimeters, and the profile shape. For instance, a label reading 4PK1000 refers to a belt with four ribs and a circumference of 1000 mm.

Sizes can vary, so it is important to refer to the manufacturer’s specifications or a reliable belt catalog when identifying the correct dimensions. The correct belt size not only ensures proper fitment and effectiveness but also prolongs the life of both the belt and the components it drives.

4pk belt sizes

Choosing the Right 4PK Belt

Selecting the right 4PK belt involves several considerations

1. Measure Accurately To determine the right size, measure the length of the old belt or the groove section where the belt will be installed. Use a measuring tape, and make sure to measure the entire circuit the belt will follow.

2. Check Compatibility Ensure that the belt is compatible with your specific model of machinery or vehicle. Consult the owner’s manual or speak to a technician if you are unsure.

3. Quality Matters Opt for belts made from high-quality materials that can withstand wear and tear. Price should not be the sole determining factor; investing in a durable belt can save money in the long run by reducing replacements and maintenance.

4. Installation Proper installation of the belt is crucial. Incorrect fitting can lead to premature failure. If you’re unfamiliar with the process, seeking professional assistance might be a wise choice.

Conclusion

In conclusion, understanding 4PK belt sizes is essential for anyone involved in maintenance or repair of machinery and vehicles. These belts cater to various applications, and selecting the right size ensures efficient operation and longevity. By measuring accurately, checking compatibility, and choosing high-quality products, users can maintain their equipment’s performance and reliability. Whether you're a mechanic, engineer, or DIY enthusiast, the right 4PK belt can make all the difference in your project's success.

-

Upgrade Power Steering Pump Belt for Smooth, Quiet Operation

NewsAug.27,2025

-

Precision Timing Belt & Chain: Engine Performance & Durability

NewsAug.26,2025

-

Precision Lathe Drive Belts: Durable & Reliable Performance

NewsAug.25,2025

-

84.5 Serpentine Belt: Durable & Precision Fit for Your Engine

NewsAug.24,2025

-

Premium Ribbed Drive Belts for Quiet Power Transmission

NewsAug.23,2025

-

High-Performance Vehicle Timing Belt for Engine Precision

NewsAug.22,2025