- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

डिस . 16, 2024 07:30 Back to list

poly v belt drive

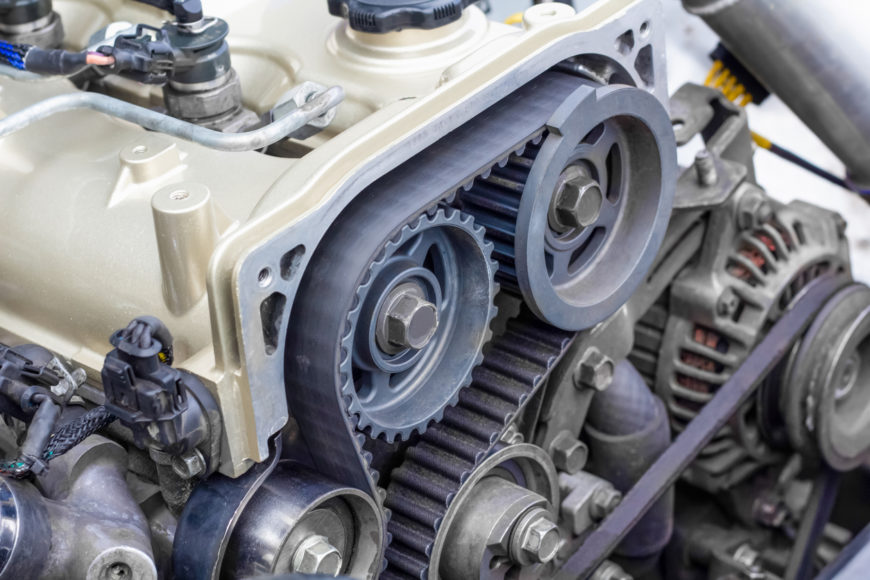

Understanding Poly V Belt Drives Efficiency and Versatility in Mechanical Systems

In the realm of mechanical power transmission, the efficiency and durability of drive systems are paramount. Among various types of belts used in industrial applications, the Poly V belt drive stands out due to its unique design and numerous advantages. This article delves into the structure, benefits, applications, and maintenance practices associated with Poly V belt drives.

What is a Poly V Belt?

The Poly V belt, also known as a multi-ribbed belt or serpentine belt, features a series of parallel grooves that run the length of the belt. Instead of a single flat surface, the Poly V belt employs multiple ribs, allowing it to have a greater surface area for contact with the pulleys. This design significantly enhances the frictional grip between the belt and the pulleys, resulting in efficient power transmission.

Typically made from high-quality rubber compounds or thermoplastic elastomers, Poly V belts are engineered to withstand harsh operating conditions, including extreme temperatures and chemical exposure. The ribs can vary in width and height, providing flexibility to cater to specific design requirements for different applications.

Advantages of Poly V Belt Drives

1. Compact Design One of the most significant advantages of Poly V belts is their compact structure. The narrow profile allows engineers to design more compact systems, reducing space requirements in machinery and vehicles. This compactness is particularly beneficial in applications where space is at a premium.

2. High Power Transmission Efficiency The design of Poly V belts enables them to transmit power with minimal slippage, ensuring a high level of efficiency. This is particularly important in systems where power loss needs to be minimized, such as automotive engines and industrial machinery.

3. Reduced Noise Levels Poly V belts operate more quietly than traditional V-belts due to their continuous ribbed design. This feature makes them ideal for use in settings where noise reduction is a priority, such as in consumer appliances or automotive applications.

4. Flexibility Poly V belts can flex and adapt to various pulley sizes and configurations, making them suitable for a wide range of machines. Their ability to bend around smaller radii without compromising performance is advantageous in compact mechanical designs.

5. Durability and Longevity Designed to withstand high loads and adverse operating conditions, Poly V belts exhibit excellent durability. Their resistance to wear and tear translates to longer operational life, reducing the frequency of replacements and maintenance, ultimately leading to cost savings.

poly v belt drive

Applications in Industries

The versatility of Poly V belts allows them to be used across various industries. In automotive engineering, they are commonly employed in engine drive systems, powering accessories like generators, water pumps, and air conditioning units.

In manufacturing, these belts are integral to conveyor systems and automated production lines, where precise and efficient power transmission is crucial. The textiles, food processing, and HVAC industries also benefit from Poly V belts due to their efficiency and space-saving design.

Maintenance Practices

To ensure the longevity and efficiency of Poly V belt drives, regular maintenance is essential

1. Inspection Routinely check belts for signs of wear, cracking, or glazing. Any visible damage can lead to decreased performance and potential system failures.

2. Tension Adjustment Maintaining proper tension is critical for optimal performance. Loose belts can slip, leading to inefficiency, while belts that are too tight can cause excessive wear on pulleys and bearings.

3. Alignment Ensure that the pulleys are correctly aligned to prevent uneven wear and sudden failures. Misalignment can lead to belt slippage and decreased efficiency.

4. Cleanliness Keep the belt and pulleys clean. Dirt and debris can cause increased friction and wear, impacting the overall performance of the drive system.

Conclusion

Poly V belt drives represent a sophisticated choice for power transmission in various mechanical systems. Their compact design, efficiency, and versatility make them invaluable in many applications, from automotive to industrial machinery. By understanding their benefits and adhering to proper maintenance practices, industries can maximize the performance and longevity of these remarkable components, ultimately enhancing their operational efficiency.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025