- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

अक्ट . 13, 2024 12:31 Back to list

Selecting the Right PK Belt for Your Japanese Vehicle Auto Parts Guide

Understanding PK Belts for Japanese Cars

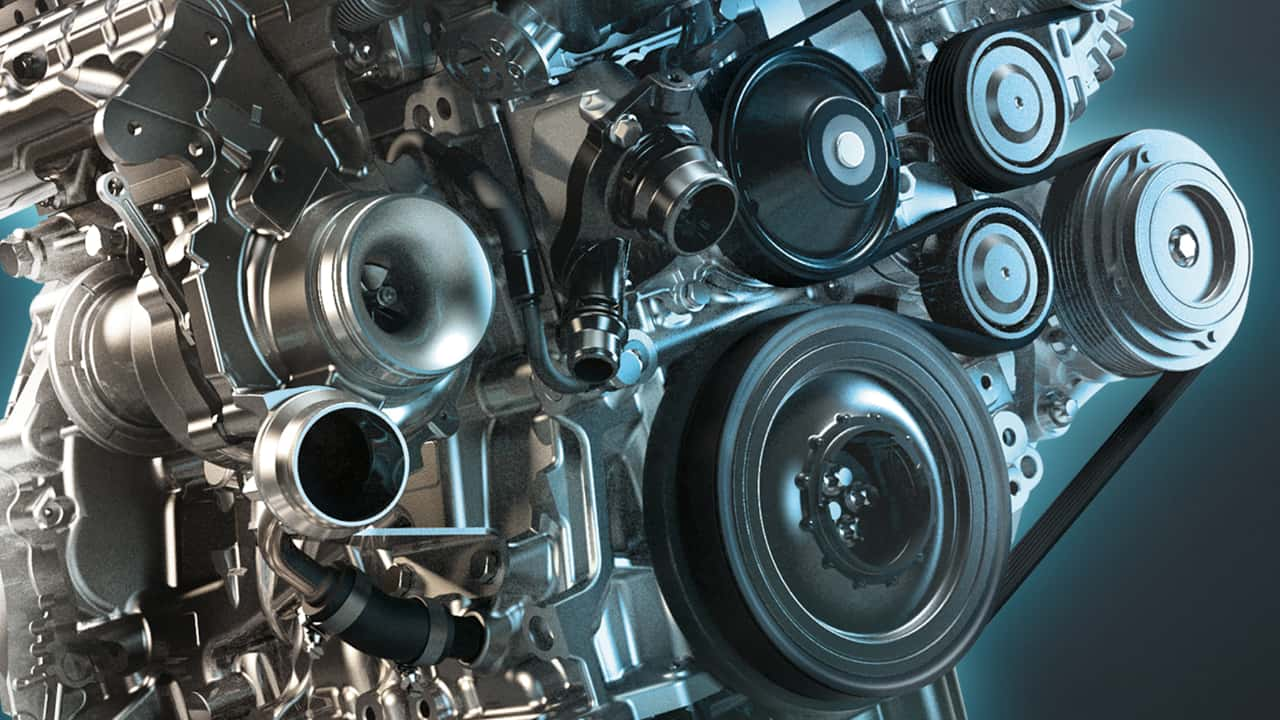

When it comes to automotive components, one of the most critical yet often overlooked parts is the belt system. In particular, PK belts, which are commonly used in Japanese cars, play a vital role in the overall functioning and efficiency of the engine. This article explores what PK belts are, their significance, and maintenance tips to ensure their longevity and performance.

What is a PK Belt?

The PK belt, also known as a poly-V belt, is a type of drive belt found in many vehicles, including a myriad of Japanese car models. The 'P' in PK stands for polyester, while 'K' refers to the belt’s design. PK belts are characterized by their unique flat profile and multiple ribs, which allow for better grip and efficient power transmission. These belts are designed to transfer power from the engine's crankshaft to various accessories like the alternator, power steering pump, water pump, and air conditioning compressor.

Importance of PK Belts

PK belts are essential for the seamless operation of auxiliary components in a vehicle. In Japanese cars, where engineering precision and efficiency are hallmarks, the use of PK belts is particularly beneficial. These belts help to reduce engine load, ensuring optimal fuel efficiency and reduction in wear and tear on the engine components. Properly functioning PK belts also contribute to lower emissions, aligning with the increasingly stringent environmental regulations in many countries.

Common Issues with PK Belts

Over time, like any mechanical component, PK belts can experience wear and tear. One of the most common issues is cracking or fraying, which can lead to belt slippage. This slippage may cause the engine to perform poorly, affecting the efficiency of all the accessories that the belt drives. In some cases, a worn-out PK belt can snap, leading to complete functional failure of critical systems like the alternator or power steering, which can pose safety risks.

Other issues may include misalignment or improper tension, which can arise from faulty pulleys or tensioners. These conditions can accelerate wear on the belt and the components it drives, leading to costly repairs if not addressed promptly.

pk belt for japanese car\/auto pk belt

Maintenance Tips

1. Regular Inspections It is advisable to check the condition of your PK belt during routine maintenance checks. Look for signs of wear, such as cracks, fraying, or signs of glazing (a shiny surface) that indicate slipping.

2. Check Tension Ensure that the belt has the correct tension. A belt that is too loose can slip, while one that is too tight can lead to premature wear on both the belt and the components it drives.

3. Alignment Checks Misaligned pulleys can cause significant belt wear. Regularly inspecting the pulleys and ensuring they are aligned can help prolong the life of the PK belt.

4. Replacement Most manufacturers recommend replacing the PK belt every 60,000 to 100,000 kilometers (about 37,000 to 62,000 miles), depending on the specific vehicle model and driving conditions. Always refer to your vehicle’s owner manual for specific guidelines.

5. Professional Help If you notice any abnormalities or are unsure about the condition of your PK belt, it is wise to consult with a qualified mechanic. They can perform a thorough inspection and recommend the necessary maintenance or replacements.

Conclusion

In conclusion, PK belts are an integral part of Japanese cars, contributing significantly to their performance and efficiency. By understanding the importance of these belts and maintaining them properly, car owners can ensure the longevity of their vehicles and avoid unnecessary repairs. Regular inspections, attention to detail, and timely replacements will keep your car running smoothly and efficiently for years to come. Remember, preventive maintenance is always more cost-effective than dealing with breakdowns!

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025