- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

मार्च . 07, 2025 02:07 Back to list

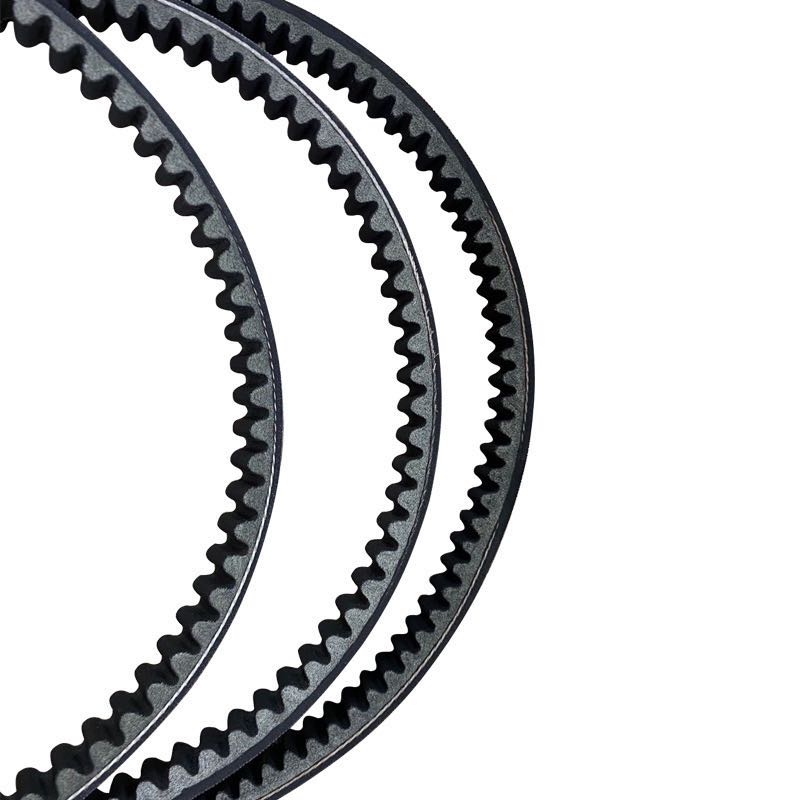

fan belt 4pk

The term fan belt 4pk refers to an essential component in numerous engine systems. Comprising high-strength materials, the 4PK fan belt falls within the Poly-V or multi-rib belts category, recognized for its efficiency in transferring energy. Engineered with precise dimensions, the 4PK designation indicates the belt's width and number of ribs, designed to accommodate specific groove profiles in pulleys to optimize engine performance.

The technological advancements in the design and material composition of fan belt 4PKs reflect the industry’s commitment to efficiency and sustainability. Modern belts integrate advanced polymers and fibers, resulting in increased resistance to stretching and improved operational quietness. These innovations contribute to lowered emissions and enhanced fuel economy by reducing the overall engine load, embodying the automotive industry’s shift towards greener technologies. Using only manufacturer-recommended fan belts guarantees conformity to specific engine requirements, preserving warranties and safeguarding against unexpected failures. Engineers and maintenance professionals need to stay informed of the latest advancements in belt technology and industry best practices to maintain their authoritative knowledge. Resources such as technical bulletins, training seminars, and trade publications are vital to continuously enhance their expertise. Confidence in the performance and reliability of the fan belt 4PK also extends to vehicle owners and operators. Transparency in communication regarding maintenance schedules, signs of wear, and replacement procedures builds trust, emphasizing the belt’s role in vehicle safety and efficiency. Engaging professionals who demonstrate not only proficiency but also ethical practices assures vehicle owners that their investments are well-protected. Manufacturer collaborations with automotive and industrial sectors further cement their authority and expertise in vehicular and equipment technologies. This synergy fosters advancements in belt technology, catering to evolving market needs while complying with stringent safety regulations. Overall, whether for vehicular, agricultural, or industrial machines, the fan belt 4PK holds an incontrovertible place in ensuring operational efficiency. Proper understanding, selection, and maintenance of this component, supported by industry expertise, guarantee enhanced performance and reliability, proving indispensable to optimal engine function.

The technological advancements in the design and material composition of fan belt 4PKs reflect the industry’s commitment to efficiency and sustainability. Modern belts integrate advanced polymers and fibers, resulting in increased resistance to stretching and improved operational quietness. These innovations contribute to lowered emissions and enhanced fuel economy by reducing the overall engine load, embodying the automotive industry’s shift towards greener technologies. Using only manufacturer-recommended fan belts guarantees conformity to specific engine requirements, preserving warranties and safeguarding against unexpected failures. Engineers and maintenance professionals need to stay informed of the latest advancements in belt technology and industry best practices to maintain their authoritative knowledge. Resources such as technical bulletins, training seminars, and trade publications are vital to continuously enhance their expertise. Confidence in the performance and reliability of the fan belt 4PK also extends to vehicle owners and operators. Transparency in communication regarding maintenance schedules, signs of wear, and replacement procedures builds trust, emphasizing the belt’s role in vehicle safety and efficiency. Engaging professionals who demonstrate not only proficiency but also ethical practices assures vehicle owners that their investments are well-protected. Manufacturer collaborations with automotive and industrial sectors further cement their authority and expertise in vehicular and equipment technologies. This synergy fosters advancements in belt technology, catering to evolving market needs while complying with stringent safety regulations. Overall, whether for vehicular, agricultural, or industrial machines, the fan belt 4PK holds an incontrovertible place in ensuring operational efficiency. Proper understanding, selection, and maintenance of this component, supported by industry expertise, guarantee enhanced performance and reliability, proving indispensable to optimal engine function.

Share:

Next:

Latest news

-

High-Quality Tensioner Belt Pulley - Durable & Efficient

NewsAug.03,2025

-

Premium Timing Belt Factory | AI-Optimized Solutions

NewsAug.02,2025

-

Premium Custom V Belts Enhanced with GPT-4 Turbo AI

NewsAug.01,2025

-

Car Serpentine Belt: AI-Optimized Performance with GPT-4-Turbo

NewsJul.31,2025

-

Heat Joining Drive Belt | High-Durability Fusion Solution

NewsJul.31,2025

-

Timing Belt Video Guide: Selection, Design & Quality Insights

NewsJul.30,2025