- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Nov . 14, 2024 15:13 Back to list

v-belts transmission 2150

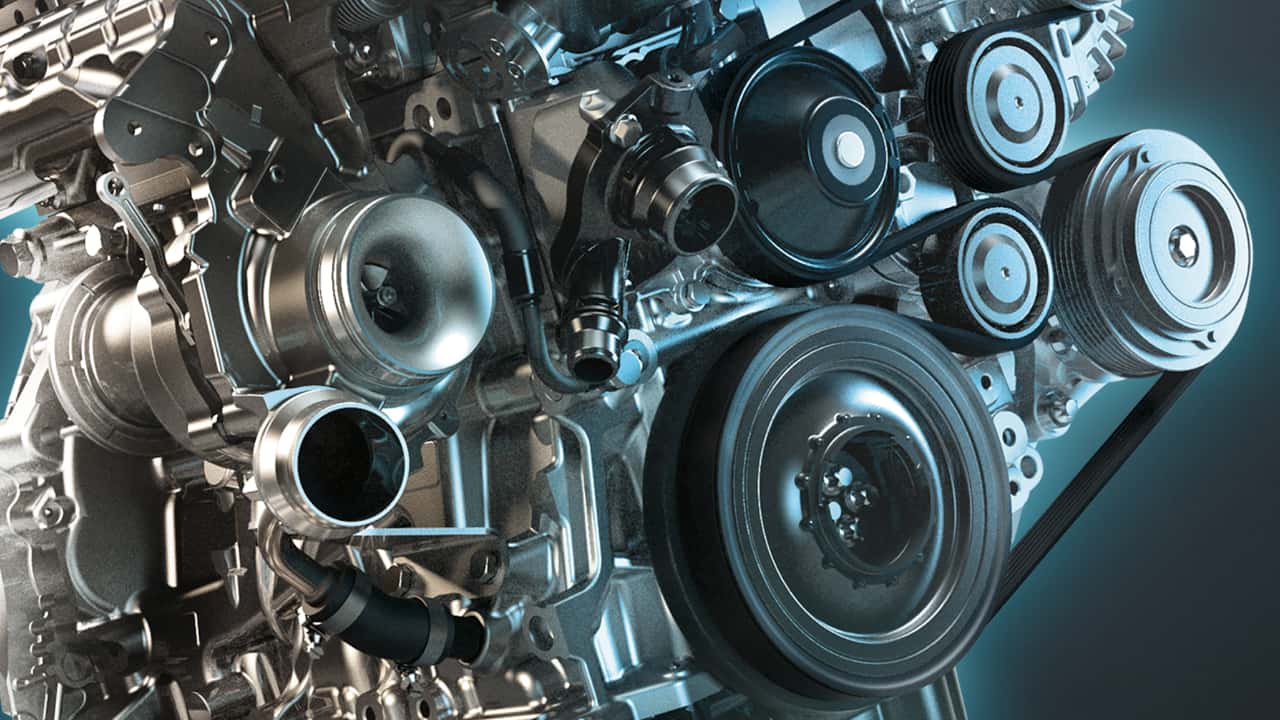

Understanding V-Belt Transmission Systems

V-belt transmission systems are essential components in many industrial and automotive applications, providing an efficient means of transferring power between shafts. The design of V-belts allows for a high degree of flexibility and adaptability, making them suitable for various machinery and engines. This article explores the principles, advantages, and applications of V-belt transmissions.

Principles of V-Belt Transmission

At the core of V-belt transmission systems are V-belts, which are trapezoidal in cross-section. This design lets the belt fit snugly into the grooves of pulleys, ensuring a secure grip that minimizes slippage. When a driving pulley (attached to a power source) rotates, it engages the V-belt, which transmits that motion to the driven pulley (attached to the machinery). This system operates on the principle of friction, where the frictional force between the belt and the pulleys is utilized to transmit torque.

The efficiency of a V-belt system can be attributed to its ability to handle a significant amount of power while maintaining relatively low levels of noise and vibration. V-belt systems can accommodate varying speeds and loads, making them versatile for different operational requirements.

Advantages of V-Belt Transmission

One of the primary benefits of V-belt transmission systems is their simplicity and ease of installation. They require minimal complex components compared to other transmission methods, such as gear systems or chain drives. This simplicity often translates to lower manufacturing costs and easier maintenance.

v-belts transmission 2150

Another advantage is the ability of V-belts to operate smoothly across a wide range of speeds and loads. They can absorb shock loads, reducing wear and tear on machinery. Additionally, V-belts are lightweight, contributing to a more efficient operation while decreasing the overall weight of the equipment.

V-belt systems are also capable of running at high speeds, which is crucial in many applications, including automotive engines and conveyor systems. The ability to change pulley diameters allows users to alter speed ratios easily, providing further flexibility in design and application.

Applications of V-Belt Transmission

V-belt transmission systems are found in various industries, including manufacturing, automotive, and agriculture. In manufacturing, they are utilized in conveyor systems to transport materials efficiently. In automotive applications, V-belts power components such as the alternator, air conditioning compressor, and water pump.

Moreover, V-belt systems are commonly used in agricultural machinery, where they provide reliable power transmission for equipment like harvesters and tractors. Their ability to handle high torque loads and diverse operating conditions makes them invaluable in these settings.

Conclusion

In summary, V-belt transmission systems play a crucial role in modern machinery and automotive applications. Their efficient power transmission, ease of installation, and adaptability to varying operational conditions make them a popular choice across multiple industries. As technology advances, innovations in V-belt design will likely continue enhancing their performance and applications, affirming their relevance in power transmission solutions.

-

Durable Diesel Engine Belt with GPT-4-Turbo AI Tech | Precision Fit

NewsAug.04,2025

-

High-Quality Tensioner Belt Pulley - Durable & Efficient

NewsAug.03,2025

-

Premium Timing Belt Factory | AI-Optimized Solutions

NewsAug.02,2025

-

Premium Custom V Belts Enhanced with GPT-4 Turbo AI

NewsAug.01,2025

-

Car Serpentine Belt: AI-Optimized Performance with GPT-4-Turbo

NewsJul.31,2025

-

Heat Joining Drive Belt | High-Durability Fusion Solution

NewsJul.31,2025