- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Oct . 18, 2024 08:56 Back to list

Exploring the Advantages of Silent Sync Belts in Modern Machinery and Equipment

Understanding the Silent Sync Belt A Revolution in Quiet Performance

The advancement in mechanical engineering and machinery design has led to significant innovations in power transmission systems. Among these innovations is the silent sync belt, a breakthrough component that promises not only efficiency but also exceptional noise reduction. The silent sync belt combines traditional belt mechanics with modern materials and design, resulting in a product that is well-suited for various applications, from automotive to industrial environments.

What is a Silent Sync Belt?

A silent sync belt, often known as a synchronous or timing belt, is designed to maintain precise timing between rotating shafts. Unlike traditional belts that often rely on friction to transfer power, synchronous belts utilize teeth that interlock with corresponding grooves on pulleys. This feature allows for a more consistent and controlled transfer of torque, reducing slippage and improving overall reliability.

The 'silent' aspect of the silent sync belt comes from its ability to operate with minimal noise. Traditional rubber belts can create vibrations and noise during operation, especially at high speeds. Silent sync belts, on the other hand, are crafted using advanced materials and geometries that dampen sound and vibrations, making them especially desirable in noise-sensitive environments.

Advantages of Silent Sync Belts

1. Noise Reduction The most standout feature of the silent sync belt is its remarkably low operational noise. This makes it an ideal choice for applications that require quiet operation, such as in robotics, drafting machines, and enclosed machinery.

2. High Efficiency The tooth-and-groove design allows for high torque transmission without slippage. This efficiency translates to better energy consumption, less heat generation, and extended lifespan for both the belt and the connected machinery.

3. Durability Silent sync belts are constructed with advanced materials that enhance their resistance to wear, abrasions, and temperature fluctuations. This durability results in longer service intervals and reduced maintenance costs.

silentsync belt

4. Precision Performance The synchronous nature of the silent sync belt ensures precise synchronization between components, which is crucial in applications like CNC machines and 3D printers where timing accuracy can significantly affect performance and output quality.

5. Flexibility in Application The silent sync belt can be utilized in a wide range of mechanical systems, making it a versatile option for engineers and designers. Its ability to perform under various loads and speeds expands its applicability across different industries.

Applications of Silent Sync Belts

The silent sync belt finds its application in many fields. In the automotive industry, these belts are used in timing systems due to their ability to maintain precise synchronization of engine timing. This precision is crucial for the overall performance and efficiency of the engine.

In the realm of robotics, silent sync belts help powered joints and actuators operate smoothly and quietly, which is essential for robotic arms and automation systems that work alongside humans. The manufacturing sector, especially in assembly lines and conveyor systems, also benefits from silent sync belts as they enhance both performance and worker safety by minimizing noise levels.

Conclusion

The silent sync belt represents a significant development in power transmission technology. Its ingenuity lies not only in its reduced noise generation but also in its efficiency, durability, and versatility across various applications. As industries increasingly prioritize noise reduction and mechanical efficiency, the silent sync belt is set to become a standard component in machinery design. Its potential to improve workplace environments and enhance machine performance heralds a new era in engineering, where silent operation is not just a luxury, but a necessity.

As businesses continue to adopt technologies that foster sustainability and operational efficiency, investing in silent sync belts is undoubtedly a step in the right direction. The combination of innovation, precision, and quiet performance makes silent sync belts a frontrunner in the evolution of mechanical systems.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

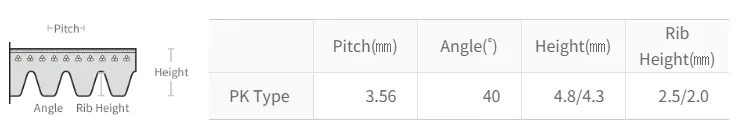

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025