- Għarbi

- Franċiż

- Russu

- Spanjol

- Portugiż

- Tork

- Armenjan

- Ingliż

- Albaniż

- Amhariku

- Ażerbajġani

- Bask

- Belarussu

- Bengali

- Bosnijan

- Bulgaru

- Katalan

- Cebuano

- Korsiku

- Kroat

- Ċek

- Daniż

- Olandiż

- Afrikan

- Esperanto

- Estonjan

- Finlandiż

- Friżjan

- Galizjan

- Ġorġjan

- Ġermaniż

- Grieg

- Guġarati

- Kreol Ħaitjan

- hausa

- Ħawajjan

- Ebrajk

- Le

- Miao

- Ungeriż

- Iżlandiż

- igbo

- Indoneżjan

- Irlandiż

- Taljan

- Ġappuniż

- Ġavaniż

- Kannada

- każak

- Khmer

- Rwandan

- Korean

- Kurdi

- Kirgiż

- TB

- Latin

- Latvjan

- Litwan

- Lussemburgiż

- Maċedonjan

- Malgashi

- Malajan

- Malajalam

- Malti

- Maori

- Marathi

- Mongoljan

- Il-Mjanmar

- Nepaliż

- Norveġiż

- Norveġiż

- Oċċitan

- Pashto

- Persjan

- Pollakk

- Punġabi

- Rumen

- Samoan

- Galliku Skoċċiż

- Serb

- Ingliż

- Shona

- Sindhi

- Sinħaliż

- Slovakk

- Sloven

- Somali

- Sundaniż

- Swaħili

- Svediż

- Tagalog

- Taġik

- Tamil

- Tatar

- Telugu

- Tajlandiż

- Turkmeni

- Ukrain

- Urdu

- Uighur

- Użbek

- Vjetnamiż

- Welsh

- Għajnuna

- Jiddix

- Joruba

- Żulu

May . 09, 2025 15:57 Lura għal-lista

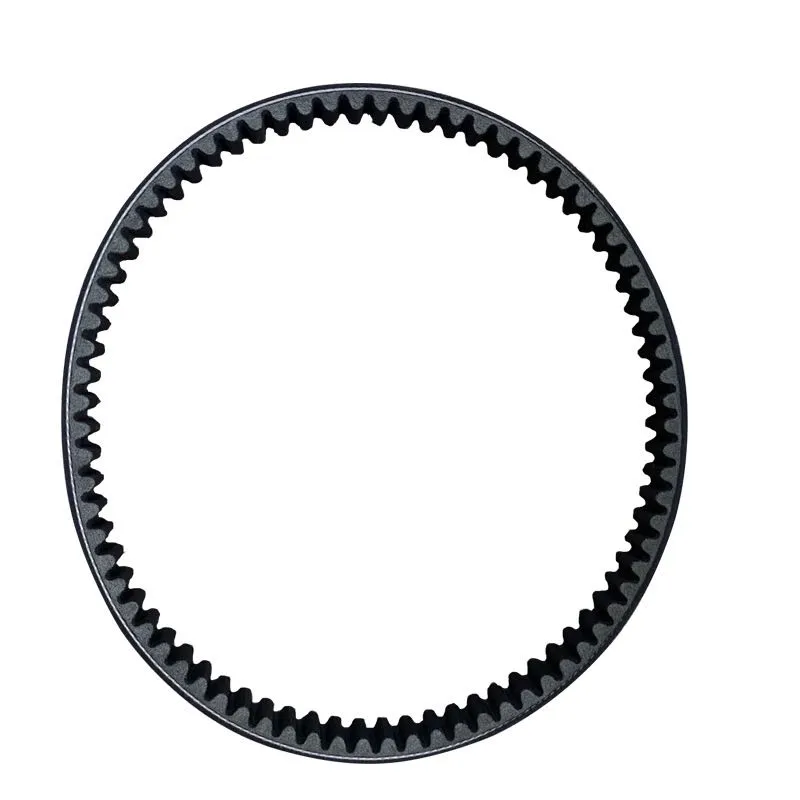

Power Transmission Redefined: Linked V Belt Technology

The evolution of engine components has led to smarter, more adaptable solutions for power transmission—one of the most revolutionary being the linked v belt. Unlike traditional drive belts, the linked v belt offers flexibility, strength, and customization without sacrificing performance. Whether it's in a car engine or an industrial machine, this innovation is rapidly becoming the go-to solution for professionals who demand reliability with convenience.

Linked V Belt vs Traditional Multi-Wedge Belt: A Clear Advantage

When comparing a linked v belt to a traditional multi-wedge belt, the difference lies not only in the construction but also in the application flexibility and service life. A multi-wedge belt—while effective in high-speed, high-load environments—relies heavily on exact pulley alignment and precise tension to operate efficiently. In contrast, the linked v belt is made of interlocking polyurethane links reinforced with internal polyester fabric, providing superior adaptability and resistance to misalignment.

Because the linked v belt does not require disassembly of machinery or complicated installation tools, it can be installed in tight spaces with minimal downtime. This gives it a tremendous edge over multi-wedge belts, particularly in maintenance-intensive applications. For automotive mechanics, this means faster service times and less disruption when replacing worn components.

Additionally, the noise level associated with multi-wedge belts increases as they wear out. The linked v belt remains quiet, stable, and vibration-free for much longer due to its superior damping characteristics and stretch resistance.

Traditional V-Belt vs Linked V Belt: Which One Lasts Longer?

Traditional V-belts may still be widely used, but their performance limitations are being exposed by newer alternatives. A conventional V-belt is molded in a fixed size and can become brittle or stretched over time, resulting in loss of tension and slippage. However, the linked v belt is composed of removable and replaceable segments, making length adjustments simple and allowing users to build the exact belt length on-site.

Moreover, the linked v belt is not susceptible to the cracking and fraying often seen in rubber V-belts. It handles heat, oil, chemicals, and abrasion with ease. Field reports show that adjustable v belt systems can outperform and outlast traditional belts by a significant margin, especially in environments where moisture, dust, or extreme temperature changes are common.

Another key benefit is maintenance. If one segment of the linked v belt wears out, you can simply remove and replace that section without discarding the entire belt. This results in lower operating costs and faster repair cycles—making it a superior long-term investment.

Automotive Engine Integration: The Rise of Linked V Belt in Vehicle Power Systems

The growing demand for compact, high-performance vehicle engines has pushed the adoption of linked v belt systems in the automotive industry. In engine applications, the linked v belt is used for driving alternators, water pumps, air conditioning compressors, and power steering systems. Due to its superior resistance to elongation and thermal stress, it's ideally suited to handle the changing loads of modern engines.

Unlike molded belts that are sensitive to environmental changes, the linked v belt maintains consistent performance across a range of engine speeds and operating temperatures. When used in conjunction with adjustable tensioners, it delivers a smooth, continuous power supply that boosts system efficiency and minimizes belt-related failures.

Also gaining popularity is the adjustable v belt, which is often found in aftermarket kits designed for quick belt replacement without needing to remove surrounding components. This convenience is particularly valuable in complex engine layouts found in modern hybrid and turbocharged vehicles.

The a46 v belt, a specific size within this category, is frequently utilized in engine-driven accessories and agricultural equipment. Its popularity stems from the high level of customization and rugged build quality offered by the linked v belt format, even under the most demanding operating conditions.

Why Professionals Choose Linked V Belts for Maximum Reliability

Versatility is where the linked v belt truly shines. It fits pulleys of varying diameters, adapts to misalignment, and can be tensioned without specialized tools. Professionals across automotive, HVAC, and agricultural sectors are turning to adjustable v belt systems because they deliver performance and reduce downtime in the field.

The modular design ensures that one type of linked v belt can replace dozens of fixed-length V-belts, significantly reducing the need to stock multiple belt sizes. This cuts down on inventory space and simplifies repairs for technicians.

Additionally, the linked v belt is designed to meet industry standards while offering easy scalability. Need a longer belt? Add more links. A shorter one? Remove a few. This degree of flexibility is unmatched by traditional V-belts or serpentine belts, making it an invaluable asset in both emergency and planned maintenance operations.

Linked V Belt FAQs

What makes the linked v belt different from a standard V-belt?

The linked v belt is made from interlocking segments, allowing it to be customized in length, adjusted on-site, and replaced in sections. This offers far more flexibility and durability than standard molded V-belts.

Can a linked v belt be used in automotive engines?

Absolutely. The linked v belt is widely used in automotive systems to drive accessories such as water pumps, alternators, and power steering units. Its resistance to heat and vibration makes it ideal for modern engine environments.

How does the adjustable v belt benefit maintenance?

The adjustable v belt can be installed or removed without disassembling machinery, which saves time and reduces labor costs. Its adjustability means one belt type can fit many pulley setups, reducing inventory needs.

What is the role of the a46 v belt in mechanical systems?

The a46 v belt is a specific size often used in both industrial and automotive applications. It combines the modular strength of the linked v belt with the convenience of custom sizing, offering outstanding performance in medium-duty setups.

Are linked belts quieter than traditional belts?

Yes. The linked v belt absorbs vibrations and reduces noise due to its segmented design and flexible material composition. This makes it perfect for applications where silent operation is important.

-

Why Upgrade Performance with Precision Timing Belt Systems?

AħbarijietJul.21,2025

-

Stationary Engine Flat Belts Revolutionize Your Power Transmission Needs?

AħbarijietJul.21,2025

-

Discover Why Mens Motorcycle Belts Are Essential for Every Rider

AħbarijietJul.21,2025

-

Discover How Vintage Motorcycle Belts Elevate Rider Style and Safety

AħbarijietJul.21,2025

-

Could Innovation in Timing Belts Redefine Power Transmission Efficiency?

AħbarijietJul.21,2025

-

Can Motorcycle Belts Improve Your Riding Comfort and Safety?

AħbarijietJul.21,2025