- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Dec . 26, 2024 14:51 Back to list

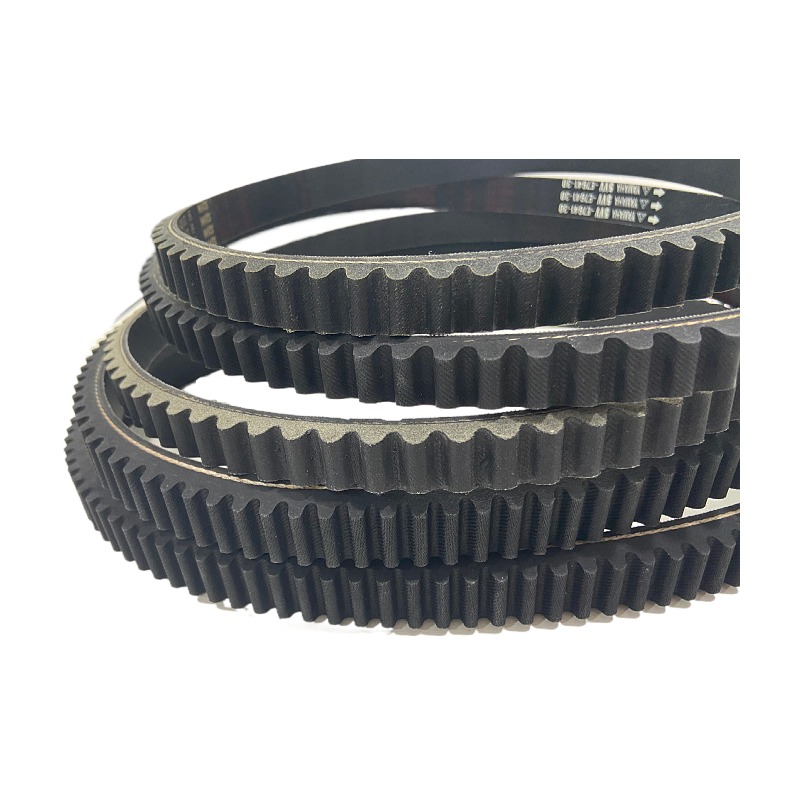

Heat Joining Process for Drive Belt Manufacturing and Application Techniques

The Importance of Heat Joining in Drive Belt Technology

In the realm of mechanical engineering and automotive design, the drive belt is a critical component that ensures the smooth transmission of power from the engine to various systems within a vehicle. As technology advances, the methods employed in the production and assembly of drive belts have evolved significantly. One of the most innovative approaches used in this field is heat joining, a technique that offers numerous advantages over traditional bonding methods.

Heat joining involves the application of controlled heat to fuse two materials together, creating a robust and seamless connection. This process is particularly favored in the production of drive belts due to its ability to enhance the durability and performance of the final product. Unlike mechanical fasteners or adhesives, which may weaken over time due to stress or environmental conditions, heat joining creates a homogeneous bond. This integration of materials results in a drive belt that can withstand high levels of tension and flexing, making it ideal for the demanding conditions of automotive applications.

One of the key benefits of heat joining technology is its efficiency. The process can be completed quickly, allowing manufacturers to increase production rates without compromising on quality. This efficiency is particularly important in the automotive industry, where timely delivery of components is crucial to meeting production schedules and maintaining competitive advantage. Heat joining also reduces the need for additional materials, such as adhesives or fasteners, which can contribute to lower manufacturing costs and a lighter overall product.

heat joining drive belt

Another significant advantage of heat joining in drive belt manufacturing is its versatility. This technique can be applied to a variety of materials commonly used in drive belts, including rubber, polyurethane, and composite materials. By using heat joining, manufacturers can create belts with specific attributes tailored to unique applications, such as increased flexibility, resistance to wear, or enhanced temperature tolerance. This customization capability means that engineers can design drive belts that meet the exact specifications of a vehicle, ultimately leading to improved efficiency and performance.

Environmental considerations are becoming increasingly important in manufacturing processes, and heat joining aligns well with modern sustainability goals. The reduction of materials needed for assembly not only minimizes waste but also decreases the overall environmental footprint associated with drive belt production. Moreover, heat joining can be executed without the use of harmful solvents or chemicals, leading to a safer working environment for factory workers and less impact on the ecosystem.

As we look to the future of automotive technology, the role of heat joining in drive belt production is likely to expand. With the rise of electric vehicles and advancements in smart technologies, there will be a demand for innovative drive systems that can support new powertrains and enhance vehicle performance. The ability of heat joining to create strong, lightweight, and efficient drive belts will be pivotal in meeting these emerging challenges.

In summary, heat joining is a transformative technique that significantly improves the manufacturing process and performance of drive belts. Its benefits—ranging from enhanced durability and efficiency to environmental sustainability—highlight the importance of adopting modern technologies in the automotive industry. As manufacturers continue to embrace innovations like heat joining, the future of drive belts looks promising, ensuring that vehicles can operate smoothly and reliably in an ever-changing automotive landscape.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025