- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

सप्टेंबर . 28, 2024 03:37 Back to list

Understanding the Importance and Functionality of Round Drive Belts in Machinery

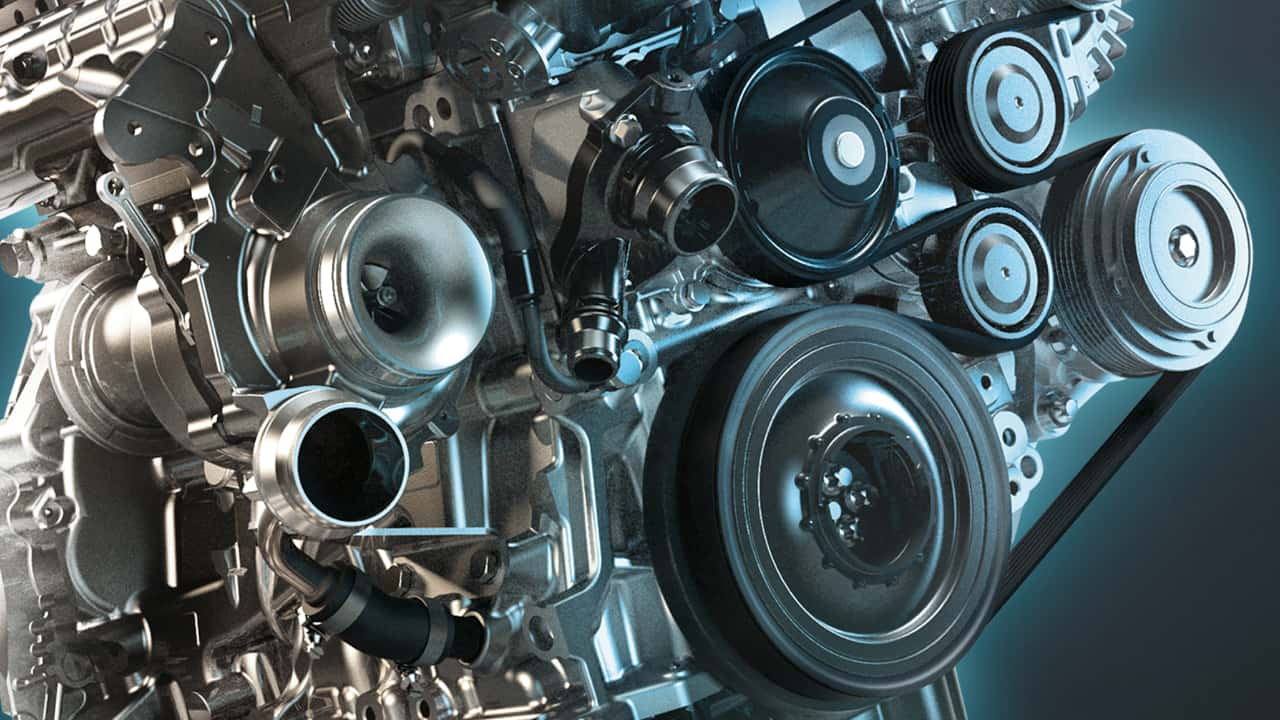

Understanding Round Drive Belts Essential Components in Mechanical Systems

Round drive belts are crucial elements in various mechanical systems, widely used for power transmission in different applications, ranging from industrial machinery to home appliances. Made from durable materials such as rubber, polyurethane, or silicone, these belts are designed to efficiently transmit power between rotating shafts while minimizing slip and wear.

Structure and Design

Round drive belts possess a circular cross-section, which distinguishes them from flat belts or V-belts. This design allows for even distribution of tension along the belt, offering a smooth transmission of power. The round shape also enables the belt to wrap around pulleys more easily, which is particularly beneficial in applications where space is limited.

Applications

The applications of round drive belts are diverse

. In the automotive industry, they are commonly found in systems like serpentine belts, which drive multiple peripheral devices such as the alternator, power steering pump, and air conditioning compressor. In manufacturing and assembly lines, round drive belts are used in conveyors and material handling systems, ensuring seamless operation and efficiency.round drive belts

In the realm of home appliances, these belts play a pivotal role in devices like washing machines and vacuum cleaners, where they connect motor shafts to agitators or brushes. Their ability to absorb shocks and vibrations makes them ideal for such applications, enhancing the overall durability and performance of the equipment.

Advantages

One of the primary advantages of round drive belts is their flexibility. They can easily bend around small-radius pulleys, making them suitable for compact designs. Additionally, the round profile reduces the risk of misalignment, a common issue with flat belts. This characteristic helps maintain consistent performance, prolonging the lifespan of both the belt and the machinery.

Furthermore, round drive belts offer excellent resistance to wear and environmental factors. Many are designed to withstand temperature fluctuations, exposure to oils, and various chemicals, making them suitable for harsh operating conditions. This resilience not only enhances their durability but also reduces maintenance costs.

Conclusion

In summary, round drive belts are integral to the functionality of many mechanical systems across different industries. Their unique design, coupled with robust material composition, makes them ideal for transmitting power efficiently and reliably. As technology continues to advance, the development of innovative round drive belts will likely enhance performance further, ensuring that they remain a vital component in the machinery of the future. Whether in industrial or domestic applications, understanding the role of round drive belts is essential for anyone involved in engineering, manufacturing, or equipment maintenance.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025