- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

12-р сар . 04, 2024 15:55 Back to list

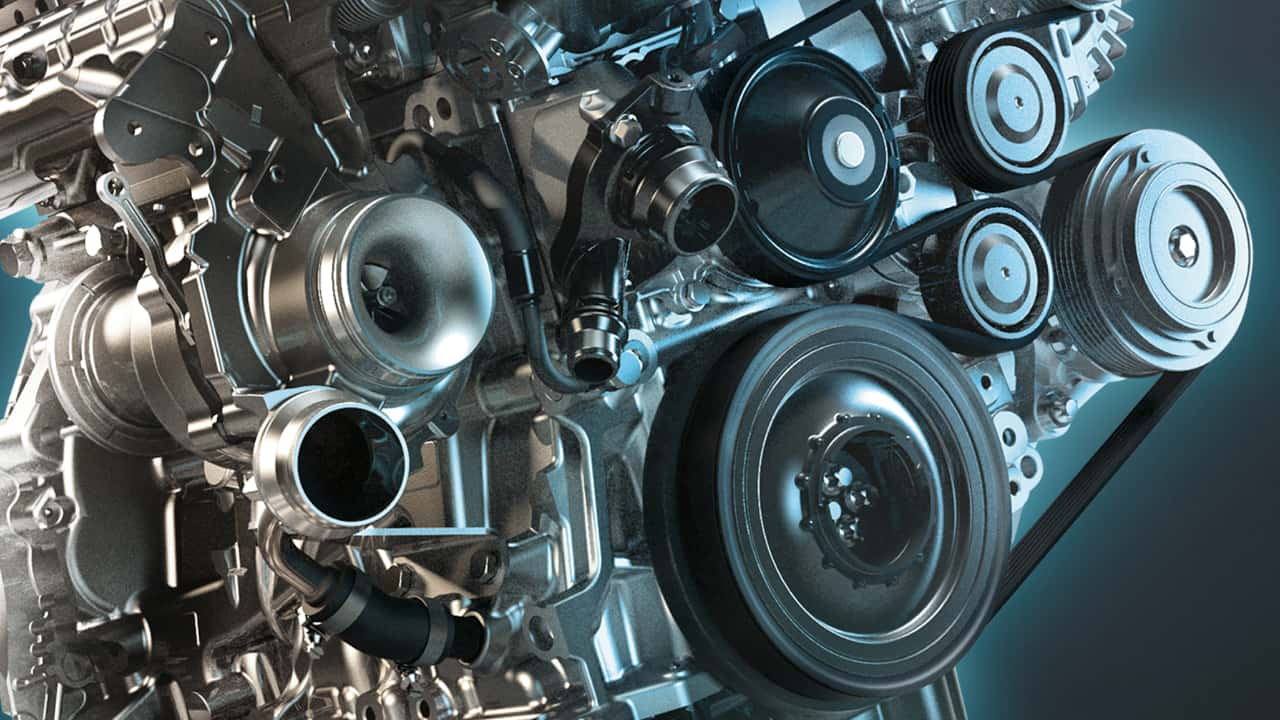

V Ribbed Belt Pulley Design and Its Applications in Mechanical Systems

The Importance of V Ribbed Belt Pulleys in Modern Machinery

In today’s fast-paced industrial world, efficiency and reliability are paramount. One of the essential components that contribute to these attributes in a variety of machines is the V ribbed belt pulley. As the backbone of many power transmission systems, these pulleys offer numerous advantages that make them invaluable in manufacturing, automotive, and various mechanical applications.

What are V Ribbed Belt Pulleys?

V ribbed belt pulleys, also known as serpentine pulleys or multi-ribbed pulleys, are designed to work with V ribbed or serpentine belts. These belts feature a series of longitudinal grooves or ribs, allowing them to grip tightly onto the surfaces of the pulley. This design increases the contact area and enhances grip, leading to improved power transmission efficiency. The smooth and continuous surface of the V ribs facilitates minimal slippage, thereby maximizing the transfer of motion and force.

Advantages of V Ribbed Belt Pulleys

1. Enhanced Grip and Power Transmission One of the most significant advantages of using V ribbed belt pulleys is their superior grip. The multiple ribs on the belt distribute the load evenly across a larger surface area, resulting in reduced wear and tear. This design minimizes slippage and maximizes torque transfer, making them ideal for heavy-duty applications.

2. Reduced Noise and Vibration The multi-ribbed design helps to dampen vibrations, leading to smoother operation. This characteristic is particularly beneficial in automotive applications where excessive noise and vibration can impact comfort and perception of quality. The efficient operation of V ribbed belts and pulleys contributes to quieter machinery, which is a significant advantage in both industrial and consumer contexts.

3. Compact Design V ribbed belts provide a more compact solution compared to traditional single V belts. The ability to transmit power effectively with fewer components allows manufacturers to design smaller machinery without compromising performance. This compactness translates to space-saving benefits on factory floors and in automotive engine compartments.

v ribbed belt pulley

4. Longer Lifespan Due to their design that minimizes slippage and wear, V ribbed belt pulleys often have a longer service life than traditional belt systems. This longevity reduces the frequency of maintenance and replacement, resulting in lower operating costs for businesses. Additionally, a longer lifespan can lead to reduced downtime, allowing for higher productivity rates.

5. Versatility V ribbed belt pulleys are versatile and can be found in various applications ranging from automotive engines and HVAC systems to industrial machinery and agricultural equipment. Their adaptability to different settings makes them a preferred choice for engineers and machinery designers.

Applications in Different Industries

- Automotive Industry In vehicles, V ribbed belt pulleys play a crucial role in the engine's operation, powering essential components such as alternators, water pumps, air conditioning compressors, and power steering pumps. The reliable power transfer provided by these pulleys ensures that vehicles function optimally under varying load conditions.

- Manufacturing In manufacturing environments, V ribbed belt pulleys are utilized in conveyor systems, robotic arms, and various other machinery. Their ability to handle heavy loads and transmit power efficiency makes them essential in keeping production lines running smoothly.

- HVAC Systems In heating, ventilation, and air conditioning (HVAC) systems, V ribbed belt pulleys are critical for driving fans, compressors, and other components. The reliability and efficiency of these pulleys are vital for maintaining indoor climate control, which is essential for comfort and productivity.

Conclusion

V ribbed belt pulleys are a key component in the efficiency and reliability of modern machinery. Their superior grip, reduced noise, compact design, longer lifespan, and versatility across various applications make them indispensable in the automotive, manufacturing, and HVAC industries. As technology progresses and industries seek even more efficient solutions, the role of V ribbed belt pulleys in power transmission systems is sure to expand. Investing in high-quality V ribbed belt pulleys is not just a choice; it's a commitment to enhancing operational efficiency and reliability in a rapidly evolving industrial landscape.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025