- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

12-р сар . 11, 2024 08:53 Back to list

synchronous belt

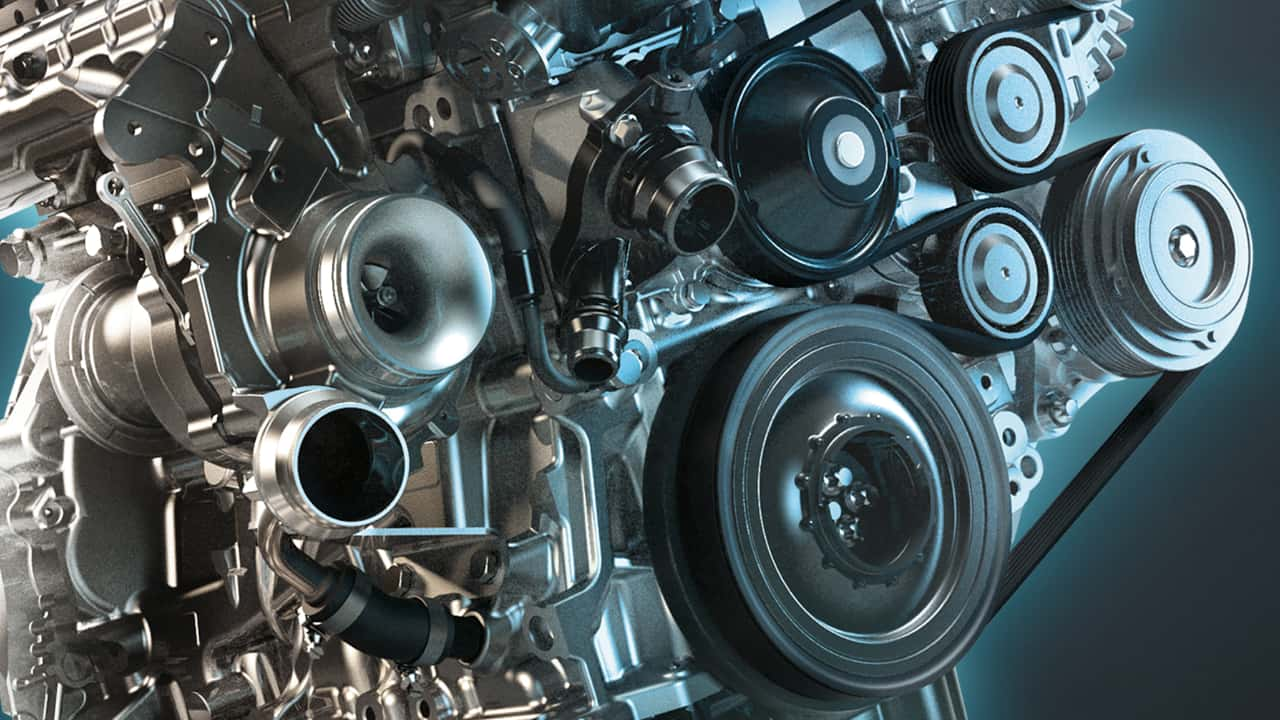

Understanding Synchronous Belts A Comprehensive Guide

Synchronous belts, often referred to as timing belts, are crucial components in various mechanical systems, primarily used for power transmission in machines and engines. These belts are designed to ensure that the rotational motion of one component directly corresponds to another, maintaining precise timing and reducing slippage. This article will delve into the fundamentals of synchronous belts, their design, advantages, applications, and maintenance considerations.

What is a Synchronous Belt?

A synchronous belt is a toothed belt that operates on the basis of positive engagement between the belt and a series of pulleys. Unlike traditional V-belts that rely on friction to transmit power, synchronous belts have teeth that fit into corresponding grooves on the pulleys. This unique design provides a distinct advantage in scenarios where precise timing is critical. By maintaining exact synchronization between connected components, these belts ensure smooth and efficient operation in various applications.

Design Features of Synchronous Belts

Synchronous belts are available in various designs and materials, depending on their intended use. Typically made from rubber or polyurethane, these belts can include reinforcing materials such as fiberglass or steel cords to increase strength and durability. The tooth profile, pitch, and width of the belt are critical factors that influence its performance. Common tooth profiles include trapezoidal and round types, each suited to specific applications.

1. Tooth Design The configuration of the teeth is fundamental to the belt’s performance. The teeth must be designed to fit precisely into the pulleys to prevent slippage, which ensures that the timing remains accurate.

2. Pitch Pitch refers to the distance between the centers of two adjacent teeth. A smaller pitch allows for higher flexibility and precision, making it suitable for dynamic and compact applications.

3. Width and Strength Ratings The width of a synchronous belt correlates with its load-carrying capacity. Wider belts can transmit higher power, making them ideal for heavy-duty applications.

Advantages of Synchronous Belts

The use of synchronous belts offers several significant advantages over other types of belts

1. Precision Timing One of the primary benefits is their ability to maintain precise timing. This precision is especially important in applications such as automotive engines, where the synchronization of the crankshaft and camshaft is crucial for optimal performance and efficiency.

2. Minimal Slippage The positive engagement of the belt and pulleys significantly reduces slippage, resulting in more reliable performance and increased overall efficiency.

synchronous belt

3. Low Noise Levels Synchronous belts operate quietly compared to chain drives and other mechanisms, making them ideal for applications where noise reduction is a priority.

Applications of Synchronous Belts

Synchronous belts are utilized in a wide range of applications. Key sectors include

- Automotive Industry In automotive engines, synchronous belts are used to connect the crankshaft to the camshaft, ensuring that valves open and close at the correct timing relative to the pistons. - Industrial Machinery Synchronous belts drive various equipment, including conveyor systems, robotic arms, and packaging machines, where precision and reliability are paramount.

- HVAC Systems In heating, ventilation, and air conditioning systems, synchronous belts help control fans and pumps to maintain consistent airflow and temperature.

- Consumer Electronics Devices such as printers and 3D printers rely on synchronous belts for precise movement, contributing to better product quality and efficiency.

Maintenance Considerations

To ensure optimal performance, synchronous belts require regular maintenance. Key maintenance practices include

- Inspection Regularly check for signs of wear, cracking, or fraying. Early detection of damage can prevent more significant issues. - Proper Tensioning Ensure the belt is correctly tensioned, as both over-tightening and slackness can lead to premature wear or failure.

- Alignment Misalignment can cause uneven wear and excessive noise, so it’s essential to maintain proper alignment between the belt and pulleys.

Conclusion

Synchronous belts play an indispensable role in modern mechanical systems, offering precision, reliability, and efficiency. Their unique design and expansive range of applications make them a critical component in various industries. Understanding their features, advantages, and maintenance needs can help users leverage their benefits effectively, ensuring optimal performance in their respective systems. As technology advances and demands for precision increase, the role of synchronous belts will continue to be indispensable across many sectors.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025