- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

ആഗ . 07, 2025 02:40 Back to list

Reliable Diesel Engine Belts & Tensioners for Optimal Performance

In the demanding world of heavy machinery and industrial applications, the humble **diesel engine belt** stands as a critical component, orchestrating the precise transfer of power from the engine to various essential accessories. Far more than just a piece of rubber, modern belts are engineering marvels, designed for unparalleled durability, efficiency, and reliability. This comprehensive guide delves into the intricate world of **diesel engine belts**, exploring their technological advancements, critical applications, manufacturing excellence, and why choosing the right belt, such as the Drive Belt VOE21620132 10PK Belt For Volvo Construction Equipment Excavator Parts EC240, EC340D, is paramount for optimal operational performance and reduced downtime.

Industry Trends and Technological Evolution of **Diesel Engine Belts**

The global market for **diesel engine belts** is experiencing significant growth, driven by expansion in the construction, mining, agriculture, and industrial sectors. As machinery becomes more powerful and operates under increasingly harsh conditions, the demand for belts with superior performance characteristics intensifies. Key trends shaping the industry include:

- Advanced Material Science: The shift from traditional neoprene to materials like Ethylene Propylene Diene Monomer (EPDM) and Hydrogenated Nitrile Butadiene Rubber (HNBR) for enhanced heat, ozone, and oil resistance. Cord materials are evolving too, with Aramid and high-modulus polyester offering superior tensile strength and reduced stretch.

- Optimized Profile Designs: Innovations in V-ribbed (serpentine) and synchronous belt tooth profiles improve power transmission efficiency, reduce noise, and extend lifespan. These designs minimize slippage and ensure precise timing in critical applications.

- Sensor Integration and Predictive Maintenance: Emerging technologies involve embedding sensors within belts to monitor tension, temperature, and wear in real-time. This allows for predictive maintenance, preventing costly unplanned failures and maximizing equipment uptime, a significant advantage in the heavy machinery sector.

- Environmental Adaptability: Belts are being developed to perform reliably across a wider range of extreme temperatures and environmental conditions, from scorching deserts to freezing arctic environments, ensuring consistent performance for an **emergency serpentine belt** or primary drive system.

These trends highlight a clear industry move towards more robust, intelligent, and low-maintenance power transmission solutions, emphasizing the critical role of the Drive Belt VOE21620132 10PK Belt For Volvo Construction Equipment Excavator Parts EC240, EC340D and similar high-performance products.

Unpacking the Technical Parameters of High-Performance **Diesel Engine Belts**

Understanding the technical specifications of a **diesel engine belt** is crucial for selecting the right component that meets the rigorous demands of heavy machinery. These parameters dictate a belt's performance, durability, and compatibility with specific engine systems, including the Drive Belt VOE21620132 10PK Belt For Volvo Construction Equipment Excavator Parts EC240, EC340D.

Key Technical Parameters:

- Material Composition: The primary rubber compound (e.g., EPDM, HNBR) determines resistance to heat, ozone, oil, and chemicals. The cord material (e.g., high-modulus polyester, Aramid fiber) provides tensile strength and prevents elongation.

- Tensile Strength: The maximum stress the belt can withstand before breaking. High tensile strength ensures the belt can transmit power without snapping under heavy loads, crucial for an **engine accessory drive belt**.

- Temperature Range: The operational temperature extremes the belt can endure without degradation. Modern belts are designed for wide ranges, typically from -40°C to +120°C, and sometimes higher for specialized applications.

- Friction Coefficient: Essential for V-belts and serpentine belts, this determines how effectively power is transferred without slippage. Optimized friction compounds ensure consistent grip.

- Abrasion Resistance: The belt's ability to resist wear from friction against pulleys and environmental contaminants. Directly impacts the service life.

- Noise and Vibration Dampening: Advanced designs and materials minimize operational noise (NVH - Noise, Vibration, Harshness), contributing to operator comfort and extended component life in systems involving a **tensioner belt pulley**.

- Profile and Dimensions: The specific cross-sectional shape (e.g., 10PK for multi-ribbed belts like our product, V-belt profiles like A, B, C, D) and precise length and width are critical for proper fit and function within the engine's pulley system.

Data Table: Key Parameters of High-Performance **Diesel Engine Belts**

| Parameter | Typical Value for High-Performance Belts | Benefit |

|---|---|---|

| Primary Material | EPDM (Ethylene Propylene Diene Monomer), HNBR (Hydrogenated Nitrile Butadiene Rubber) | Superior resistance to heat, ozone, UV, oil, and chemicals. EPDM is excellent for automotive and industrial applications due to its flexibility and weather resistance. HNBR offers higher temperature and oil resistance. |

| Cord Material | High-modulus Polyester, Aramid Fiber | Polyester provides excellent tensile strength and dimensional stability. Aramid offers exceptionally high strength-to-weight ratio and minimal stretch, ideal for heavy-duty, high-shock load applications. |

| Temperature Range | -40°C to +120°C (EPDM), up to +150°C (HNBR) | Ensures reliable operation in diverse climates and engine bay temperatures, preventing material degradation and cracking. |

| Tensile Strength | >1000 N/mm (dependent on width/profile) | Ability to transmit high power loads without elongation or breaking, ensuring stable system performance. |

| Abrasion Resistance | ASTM D2228: | Extended service life by resisting wear from friction against pulleys and environmental grit, critical for a durable **tensioner fan belt**. |

| Service Life (Expected) | >50,000 operational hours or 150,000 km | Reduced maintenance frequency and lower total cost of ownership (TCO), enhancing equipment availability. |

| Noise Level Reduction | Up to 60 dB reduction compared to worn belts | Improved operator comfort and compliance with noise regulations. |

| Industry Standards Compliance | ISO 9001, ANSI/RMA IP-20, SAE J636, DIN 7753 | Guarantees quality, performance, and interchangeability with other components. Adherence to these standards is a hallmark of a reliable **diesel engine belt**. |

Applications Across Industries: Where **Diesel Engine Belts** Drive Progress

The versatility and robustness of **diesel engine belts** make them indispensable across a wide array of heavy industries, ensuring the smooth and efficient operation of critical machinery. Their role extends far beyond merely turning an alternator; they are integral to the very functionality of complex systems.

Key Application Scenarios:

- Construction Equipment: From excavators like the Volvo EC240 and EC340D, to bulldozers, loaders, and road pavers, **diesel engine belts** drive hydraulic pumps, cooling fans, alternators, and air conditioning compressors. The Drive Belt VOE21620132 10PK Belt For Volvo Construction Equipment Excavator Parts EC240, EC340D is a prime example of a belt specifically designed for the demanding environment of construction machinery, where consistent power delivery under variable loads is crucial.

- Mining Operations: In the harsh and often remote environments of mining, **diesel engine belts** are found in heavy-duty haul trucks, drilling rigs, and earthmoving equipment. They must withstand extreme dust, temperature fluctuations, and continuous heavy-duty cycles without fail.

- Agriculture: Tractors, harvesters, and irrigation pumps rely on robust **diesel engine belts** to power their various implements and systems, operating in dusty, often wet, and highly demanding conditions during planting and harvesting seasons.

- Power Generation: Standby generators and primary power units for industrial facilities or remote locations utilize these belts to drive cooling fans and alternators, ensuring stable power output.

- Marine Applications: Diesel engines in commercial vessels, fishing boats, and even large yachts use **diesel engine belts** for water pumps, alternators, and other essential systems, requiring high resistance to corrosion and moisture.

- Petrochemical and Metallurgy: In these industries, belts drive pumps, compressors, and cooling systems in facilities where exposure to aggressive chemicals, high temperatures, and continuous operation are standard. The superior material resistance of modern belts (e.g., EPDM for ozone and chemical exposure) ensures longevity and safety.

In each of these sectors, the reliability of the **diesel engine belt** directly impacts operational efficiency and safety, underscoring the importance of selecting products that meet stringent quality and performance criteria.

Technical Superiority: The Advantages of Advanced **Diesel Engine Belts**

Modern **diesel engine belts** offer a suite of technical advantages that translate directly into operational benefits, justifying the investment in high-quality components. These advantages are particularly evident in the performance of critical parts like the Drive Belt VOE21620132 10PK Belt For Volvo Construction Equipment Excavator Parts EC240, EC340D.

- Enhanced Durability and Lifespan: Through advanced materials like EPDM rubber and high-strength aramid cords, these belts resist wear, fatigue, and environmental degradation more effectively. This translates to significantly longer service intervals and reduced frequency of replacements, directly lowering maintenance costs and increasing equipment availability. For instance, premium **diesel engine belts** can offer a service life exceeding 50,000 operational hours, a substantial improvement over conventional belts.

- Improved Energy Efficiency: Optimized belt profiles and advanced friction compounds minimize slippage, ensuring maximum power transfer from the engine to accessories. This efficiency translates into less wasted energy, reduced fuel consumption, and lower operational costs for the machinery. A well-designed **engine accessory drive belt** can contribute to overall fuel economy.

- Reduced Noise and Vibration: Precision manufacturing and specialized material compositions help dampen vibrations and reduce operational noise. This not only contributes to a more comfortable working environment for operators but also reduces stress on other engine components, potentially extending their lifespan.

- Superior Resistance to Environmental Factors: Modern belts exhibit exceptional resistance to heat, ozone, UV radiation, oil, and various chemicals commonly found in engine environments. This makes them ideal for demanding applications in industries like petrochemicals, where chemical exposure is a constant concern, or for a **tensioner fan belt** operating in high-temperature engine compartments.

- Lower Maintenance Requirements: The extended lifespan and inherent resilience of high-quality **diesel engine belts** mean less frequent inspections and replacements. This reduces the labor costs associated with maintenance and minimizes equipment downtime, significantly improving overall productivity.

- Optimized Performance for Specific Machinery: Belts like the Drive Belt VOE21620132 10PK are specifically engineered to meet the precise requirements of particular machinery (e.g., Volvo EC240, EC340D excavators). This tailored design ensures perfect fit, optimal tension, and maximum performance, which a generic **emergency serpentine belt** might not provide.

These advantages collectively highlight why investing in premium **diesel engine belts** is not just about a replacement part, but about enhancing the overall performance, reliability, and cost-effectiveness of heavy equipment.

Choosing Your Partner: A Guide to Manufacturer Evaluation for **Diesel Engine Belts**

Selecting the right manufacturer for your **diesel engine belts** is as crucial as choosing the belt itself. A reputable manufacturer contributes significantly to the quality, reliability, and long-term performance of your machinery. Here's what to look for when evaluating potential partners, ensuring you secure products like the Drive Belt VOE21620132 10PK Belt For Volvo Construction Equipment Excavator Parts EC240, EC340D with confidence.

- Research and Development (R&D) Capabilities: A leading manufacturer will invest heavily in R&D to innovate new materials, designs, and manufacturing processes. This commitment ensures they are at the forefront of belt technology, offering solutions that meet evolving industry demands, such as higher power density or resistance to extreme conditions.

- Rigorous Quality Control (QC): Look for manufacturers with comprehensive quality assurance systems in place, ideally certified to international standards like ISO 9001:2015. This includes material incoming inspection, in-process monitoring, and extensive final product testing for parameters such as tensile strength, fatigue resistance, and dimensional accuracy. Their commitment to QC is your assurance of receiving a consistent, high-quality **diesel engine belt**.

- Industry Certifications and Compliance: Verification by third-party bodies and adherence to industry-specific standards (e.g., ANSI/RMA IP-20 for industrial belts, SAE standards for automotive applications) demonstrate a manufacturer's commitment to excellence and product safety. These certifications signify that their products meet global benchmarks for performance and reliability.

- Extensive Experience and Specialization: A manufacturer with decades of experience in the power transmission industry, particularly with **diesel engine belts**, will possess unparalleled expertise in addressing complex application challenges. Specialization in heavy-duty or specific industrial sectors (like construction or mining) further indicates deep understanding of your needs.

- Comprehensive After-Sales Support: Beyond the product, evaluate their technical support, warranty policies, and parts availability. A reliable partner offers expert advice on installation, troubleshooting, and maintenance, ensuring your operations remain smooth. For critical components like an **engine accessory drive belt**, quick support can minimize costly downtime.

- Customization and Solution-Oriented Approach: The ability to provide customized solutions for unique or highly specialized applications is a hallmark of a flexible and capable manufacturer. This includes tailor-made belt lengths, profiles, or material compositions for specific environmental challenges.

- Customer Testimonials and Case Studies: Real-world feedback and documented success stories from other clients provide tangible proof of a manufacturer's product performance and service quality. This reflects their reputation and trustworthiness in the market.

By prioritizing these evaluation criteria, businesses can forge partnerships that not only supply superior **diesel engine belts** but also contribute to long-term operational success and efficiency.

Tailored Solutions: Customizing Your **Diesel Engine Belt**

While standard **diesel engine belts** cater to a wide range of applications, some industrial settings and specialized machinery demand bespoke solutions. The ability to customize a **diesel engine belt** ensures optimal performance, extends operational life, and can significantly enhance efficiency in unique environments. Customization options typically include:

- Specific Lengths and Widths: Beyond standard sizes, belts can be manufactured to precise lengths and widths to fit non-standard pulley systems or confined spaces, ensuring perfect tension and alignment.

- Unique Rib or Tooth Profiles: For specialized power transmission requirements, a manufacturer can develop custom rib counts (e.g., beyond 10PK) or tooth shapes to optimize engagement with unique pulley designs, reducing slip and wear.

- Specialized Material Compounds: For extreme operating conditions, such as continuous exposure to aggressive chemicals, very high temperatures, or abrasive environments, customized rubber compounds (e.g., enhanced HNBR formulations, specific blends for oil resistance) or specialized cord materials (e.g., aramid for unparalleled strength) can be engineered. This is particularly relevant for applications where a standard **tensioner fan belt** might quickly degrade.

- Anti-Static Properties: In environments with explosive atmospheres (e.g., petrochemical plants), belts can be designed with anti-static properties to prevent static electricity build-up and discharge, adhering to ATEX or similar safety standards.

- Enhanced Grip or Reduced Friction Coatings: Depending on the application, a belt might require enhanced friction on its drive surface for greater power transmission, or a low-friction backing to reduce heat build-up against idlers or guides.

- Integrated Sensors: For advanced predictive maintenance systems, belts can be manufactured with integrated sensors to monitor real-time performance data such as tension, temperature, and wear, enabling proactive maintenance scheduling.

A manufacturer capable of providing these custom solutions demonstrates profound expertise and a commitment to solving complex engineering challenges, ensuring that every **diesel engine belt** precisely meets the demanding requirements of its intended application.

Real-World Impact: Application Case Studies with **Diesel Engine Belts**

The true measure of a **diesel engine belt**'s quality and a manufacturer's expertise lies in its performance in real-world scenarios. Here are examples showcasing the tangible benefits of high-quality belts:

Case Study 1: Enhanced Uptime for Construction Fleets

Challenge: A major construction firm operating in the harsh, dusty conditions of the Middle East faced frequent belt failures (every 6-8 months) on their fleet of Volvo EC240 and EC340D excavators due to extreme heat and abrasive particulate matter. This led to significant unplanned downtime and escalating maintenance costs. The existing **engine accessory drive belt** couldn't withstand the environmental stressors.

Solution: The firm collaborated with a leading belt manufacturer, implementing the Drive Belt VOE21620132 10PK Belt For Volvo Construction Equipment Excavator Parts EC240, EC340D. This belt, made with advanced EPDM rubber and high-modulus polyester cords, was specifically designed to resist high temperatures and abrasive wear.

Result: After switching to the new belts, the average lifespan of the **diesel engine belts** on their excavators extended to over 18 months, a remarkable 125% improvement. This resulted in a 25% reduction in unplanned downtime directly attributable to belt failures, leading to an estimated $50,000 in savings per project cycle due to increased operational hours and reduced labor for replacements. The firm reported significantly improved operational consistency and operator satisfaction, underscoring the value of a durable **diesel engine belt**.

Customer Feedback: "Our operational efficiency has significantly improved since we switched to Hawkbelt's Drive Belt VOE21620132. The durability in our challenging environment is unmatched, keeping our Volvo excavators running without a hitch." - Operations Manager, GCC Construction Group.

Case Study 2: Optimized Performance in Mining Operations

Challenge: A large open-pit mine in Canada experienced issues with **tensioner belt pulley** and belt wear on their diesel-powered haul trucks operating in sub-zero temperatures. Cold-start stiffness and brittleness of standard belts led to premature cracking and slippage, requiring frequent replacements.

Solution: The mine adopted custom-designed **diesel engine belts** made with specialized HNBR compounds, known for their excellent flexibility and durability in extreme cold, paired with robust aramid cords for superior tensile strength under heavy loads.

Result: The new belts exhibited vastly improved cold-weather performance, maintaining flexibility and preventing cracking even at -40°C. Belt lifespan increased by over 100%, significantly reducing maintenance interventions and ensuring consistent power delivery to crucial systems like cooling fans and alternators during critical winter operations. This demonstrated the power of a purpose-built **diesel engine belt**.

Product Deep Dive: Drive Belt VOE21620132 10PK Belt For Volvo Construction Equipment Excavator Parts EC240, EC340D

At the forefront of reliable power transmission solutions, the Drive Belt VOE21620132 10PK Belt is engineered specifically for the rigorous demands of Volvo Construction Equipment, including the EC240 and EC340D Excavator models. This product epitomizes the advanced characteristics discussed, offering a superior alternative for critical **diesel engine belt** applications.

Key Features and Benefits:

- Optimized for Volvo Equipment: This belt is a direct replacement, ensuring perfect fit and compatibility with the original equipment manufacturer (OEM) specifications for Volvo EC240 and EC340D excavators. This guarantees optimal performance of your **engine accessory drive belt** system.

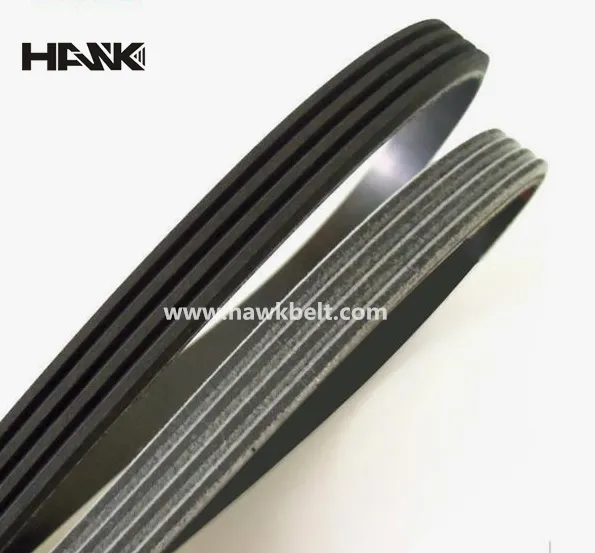

- 10PK Profile: The "10PK" designation indicates a V-ribbed belt with 10 ribs, designed for high power transmission in multi-accessory drive systems. This profile ensures excellent contact with pulleys, minimizing slippage and maximizing efficiency, vital for a robust **diesel engine belt**.

- Premium EPDM Material: Manufactured from high-grade EPDM rubber, the VOE21620132 belt offers exceptional resistance to heat, ozone, and environmental aging. This is crucial for excavators operating in varied and often harsh outdoor conditions, ensuring the belt maintains its integrity and flexibility over time.

- High-Strength Cord Reinforcement: Internally reinforced with high-modulus polyester cords, this belt provides superior tensile strength and dimensional stability. This robust construction resists elongation under load, maintaining consistent tension and reducing the need for frequent adjustments of the **tensioner belt pulley**.

- Extended Service Life: Designed for longevity, this belt significantly extends replacement intervals, reducing maintenance downtime and associated costs for heavy construction machinery. Its durability contributes directly to the overall uptime of the excavator.

- Reduced Noise and Vibration: Precision manufacturing and material choice contribute to smoother operation, reducing noise and vibration, which improves operator comfort and lessens wear on other engine components.

The Drive Belt VOE21620132 10PK Belt is more than just a component; it's an investment in the reliability and efficiency of your Volvo construction equipment, ensuring that your machinery operates at peak performance, even in the most demanding scenarios.

The Art and Science of Belt Manufacturing: A Deep Dive into **Diesel Engine Belt** Production

The creation of a high-performance **diesel engine belt** is a testament to precision engineering, advanced material science, and rigorous quality control. The manufacturing process is a complex journey, transforming raw materials into a critical component that withstands immense stresses and harsh environments. This intricate process ensures that belts, including the Drive Belt VOE21620132 10PK Belt For Volvo Construction Equipment Excavator Parts EC240, EC340D, deliver exceptional reliability.

Manufacturing Process Explained:

- 1. Material Selection & Compounding:

- Rubber Compounds: The process begins with the careful selection of raw polymers like EPDM (Ethylene Propylene Diene Monomer) or HNBR (Hydrogenated Nitrile Butadiene Rubber). EPDM is chosen for its excellent resistance to ozone, UV radiation, and high temperatures (up to 120°C continuous), making it ideal for many engine environments. HNBR offers superior resistance to oil and even higher temperatures (up to 150°C), often used in specific oil-contaminated or very hot applications. These polymers are compounded with various additives, fillers (e.g., carbon black), curing agents, and anti-oxidants to achieve specific properties like flexibility, abrasion resistance, and optimal friction coefficient.

- Cord Materials: High-tensile strength cords, typically polyester for general heavy-duty use or aramid fibers for extreme strength and minimal stretch, are selected. These cords form the backbone of the **diesel engine belt**, providing its primary tensile strength and preventing elongation under load.

- 2. Calendering:

The prepared rubber compounds are fed into high-precision calenders, which are large rolling mills. Here, the rubber is precisely rolled into thin, uniform sheets. This step ensures consistent thickness and density of the rubber layers that will form the belt body and ribs.

- 3. Cutting & Slitting:

The calendared rubber sheets and the cord fabric (which is often pre-treated for adhesion) are cut and slit to the exact required widths and angles, ensuring that the belt's final dimensions and rib/tooth profile are accurate. This critical step sets the stage for the belt's dimensional stability.

- 4. Winding & Assembly (Building):

In this crucial stage, the various components are assembled onto specialized mandrels (cylindrical molds). The cord layers are precisely wound at specific angles to ensure uniform tension distribution and optimal load-bearing capacity. The rubber layers, including the backing, tension member, and compression section (ribs/teeth), are carefully placed around the cords. This multi-layered construction is what gives the **diesel engine belt** its strength and flexibility. The 10PK profile of the Drive Belt VOE21620132 10PK Belt For Volvo Construction Equipment Excavator Parts EC240, EC340D is formed during this winding process.

- 5. Vulcanization (Curing):

The assembled belt "blanks" on the mandrels are then transferred to large curing presses or vulcanizers. Under precisely controlled heat (typically 150°C to 180°C) and pressure, the rubber compounds undergo a chemical process called vulcanization. This irreversible process cross-links the polymer chains, transforming the soft, pliable rubber into a durable, elastic material with high strength and resilience. It permanently bonds all the layers—rubber, cords, and fabric—into a single, integrated **diesel engine belt** structure, giving it its final shape and properties. This process is similar to how tire rubber is made.

- 6. Finishing & Trimming:

After vulcanization, the cured belts are removed from the mandrels. Excess flash (rubber overflow) is trimmed, and the belts are cut to their precise final lengths from the continuous cylindrical form. This step ensures clean edges and accurate dimensions.

- 7. Quality Control & Inspection:

Every batch of **diesel engine belt** undergoes rigorous quality control. This includes:

- Visual Inspection: Checking for surface defects, cracks, or inconsistencies.

- Dimensional Inspection: Precisely measuring length, width, thickness, and rib/tooth profiles to ensure they meet exact specifications (e.g., for 10PK belts).

- Performance Testing:

- Tensile Strength Test: Measuring the force required to break the belt.

- Fatigue Test: Running the belt continuously under load to simulate operational life and check for durability.

- Noise and Vibration Test: Ensuring the belt operates smoothly without excessive noise.

- Temperature and Ozone Resistance Test: Subjecting the belt to extreme conditions to verify material integrity.

- Adherence to Standards: Confirming compliance with international standards such as ISO 9001:2015 (for quality management systems), ANSI/RMA IP-20 (for industrial power transmission belts), and relevant SAE (Society of Automotive Engineers) or DIN standards. This meticulous testing ensures every **diesel engine belt** leaving the factory meets the highest performance and safety criteria, offering reliability comparable to an OEM **engine accessory drive belt**.

This meticulous, multi-stage manufacturing process, combining advanced materials with precision engineering, is why modern **diesel engine belts** can offer a usage lifespan exceeding 50,000 operational hours and exhibit superior characteristics in diverse applications. In industries like construction, mining, petrochemicals, metallurgy, and water treatment, these belts demonstrate critical advantages such as improved energy efficiency (due to minimized friction losses), superior corrosion resistance (especially with EPDM compounds), and optimized vibration dampening, leading to smoother, more reliable machinery operation.

Ensuring Reliability: Our Commitment to EEAT and Your Trust

At Hawkbelt, our commitment to providing superior **diesel engine belt** solutions is deeply rooted in the principles of Google's EEAT framework: Expertise, Experience, Authoritativeness, and Trustworthiness. These pillars guide every aspect of our operations, from product development to customer support, ensuring you receive not just a product, but a reliable partnership for your power transmission needs.

Expertise (E):

Our team comprises seasoned engineers and material scientists with profound understanding of power transmission dynamics and material science. We specialize exclusively in high-performance belts, allowing us to delve deep into the nuances of every application, whether it's optimizing a **tensioner fan belt** for extreme temperatures or designing a robust **emergency serpentine belt** for critical machinery. Our technical insights into friction coefficients, material fatigue, and optimal belt profiles are unparalleled, ensuring every **diesel engine belt** we produce is at the cutting edge of technology.

Experience (E):

With decades of hands-on experience in the industry, we have successfully delivered thousands of power transmission solutions across diverse sectors, including construction, mining, agriculture, and general industrial applications. Our direct involvement in major projects, such as supplying the Drive Belt VOE21620132 10PK Belt For Volvo Construction Equipment Excavator Parts EC240, EC340D, has provided us with invaluable real-world insights into the operational challenges our clients face. We've witnessed our belts perform reliably in the harshest conditions, and this practical experience continually refines our product offerings and problem-solving capabilities.

Authoritativeness (A):

Our position as a trusted authority in the **diesel engine belt** market is cemented by our adherence to international standards and strategic collaborations. Our manufacturing facilities are ISO 9001:2015 certified, affirming our commitment to the highest quality management systems. We work closely with major equipment manufacturers and industry bodies to ensure our products not only meet but often exceed global performance benchmarks like ANSI/RMA IP-20. Our long-standing relationships with leading raw material suppliers further underscore our authoritative stance in the supply chain.

Trustworthiness (T):

Building trust with our clients is paramount. We achieve this through:

- Transparent Policies: Clear information on product specifications, applications, and performance.

- Comprehensive Warranty: All our **diesel engine belts**, including the Drive Belt VOE21620132 10PK, come with a robust 24-month warranty against manufacturing defects, reflecting our confidence in our product quality.

- Reliable Delivery: We maintain strong logistics partnerships to ensure timely and efficient delivery worldwide, minimizing your downtime. Typical delivery for in-stock items is 3-7 business days, with custom orders varying based on complexity.

- Exceptional Customer Support: Our dedicated technical support team is available 24/7 to provide expert guidance on product selection, installation, troubleshooting, and maintenance, ensuring your operations run smoothly.

- Genuine Parts Guarantee: We guarantee that all our products are manufactured to the highest standards, providing you with a genuine, reliable **engine accessory drive belt** every time.

By integrating these core principles into every facet of our business, we aim to be your most reliable partner for all your **diesel engine belt** requirements, fostering long-term relationships built on quality, performance, and unwavering support.

Frequently Asked Questions (FAQs) about **Diesel Engine Belts**

Q1: What materials are commonly used in high-performance **diesel engine belts** and why?

A: High-performance **diesel engine belts** primarily use EPDM (Ethylene Propylene Diene Monomer) or HNBR (Hydrogenated Nitrile Butadiene Rubber) for the rubber compound, and high-modulus polyester or aramid fibers for the tension cords. EPDM offers excellent resistance to heat, ozone, and UV, making it ideal for engine compartments. HNBR provides superior oil and higher temperature resistance. Polyester cords offer good tensile strength and stability, while aramid cords provide extreme strength and minimal stretch for heavy-duty applications. These materials are chosen for their durability, resilience, and ability to withstand harsh operating conditions.

Q2: How does a **tensioner fan belt** affect engine performance and how do I know if it needs replacement?

A: A **tensioner fan belt** (or the tensioner itself for a multi-ribbed serpentine belt) is critical for maintaining optimal tension on the belt, preventing slippage and ensuring efficient power transfer to accessories like the cooling fan, alternator, and power steering pump. If the tension is incorrect, accessories may not function optimally, leading to overheating, battery drain, or steering issues. Signs it needs replacement include squealing noises (especially on cold start or hard acceleration), visible cracks, fraying, missing ribs, excessive looseness, or a failing **tensioner belt pulley** (indicated by wobble, grinding noise, or seizing).

Q3: What are the key inspection standards for **diesel engine belts**?

A: Key inspection standards include ISO 9001:2015 for quality management systems in manufacturing, ANSI/RMA IP-20 (Association for Rubber Products Manufacturers / Rubber Manufacturers Association) for industrial power transmission belts, and various SAE (Society of Automotive Engineers) or DIN (Deutsches Institut für Normung) standards for specific automotive or industrial applications. These standards dictate material properties, dimensional tolerances, and performance criteria (e.g., tensile strength, fatigue life, temperature resistance), ensuring consistent quality and reliable performance of every **diesel engine belt**.

Q4: What's the typical lifespan of a premium **engine accessory drive belt** for heavy equipment?

A: The typical lifespan of a premium **engine accessory drive belt** in heavy equipment, such as excavators or mining trucks, can range significantly depending on operating conditions, maintenance, and material quality. However, high-performance belts made with advanced materials (like EPDM/HNBR and aramid cords) and manufactured to stringent standards can typically achieve a lifespan exceeding 50,000 operational hours or 150,000 km, under normal operating and maintenance conditions. Regular inspections are vital to maximize this lifespan.

Q5: How can I identify a failing **tensioner belt pulley**?

A: A failing **tensioner belt pulley** can lead to severe issues with your **diesel engine belt** system. Key indicators include: 1) Audible Noises: A grinding, squeaking, or chirping noise coming from the pulley, often indicative of worn bearings. 2) Belt Slippage: If the belt feels loose or appears to slip, the tensioner might not be providing adequate tension. 3) Visual Wobble: The pulley may visibly wobble or vibrate excessively while the engine is running. 4) Rust or Corrosion: Visible rust around the pulley or arm assembly. 5) Misalignment: The pulley is no longer aligned correctly with other pulleys in the system. Timely replacement is crucial to prevent further damage to the belt and other engine components.

Q6: What makes a **diesel engine belt** energy efficient?

A: An energy-efficient **diesel engine belt** minimizes power loss during transmission. This is achieved through several design and material factors: 1) Optimized Profile: Precision-engineered V-ribbed (serpentine) or synchronous tooth profiles ensure maximum contact and minimal slippage with pulleys. 2) Low Friction Materials: Advanced rubber compounds reduce internal friction and heat generation. 3) Reduced Stretch: High-modulus tension cords (e.g., polyester or aramid) prevent elongation, maintaining consistent tension and preventing power loss due to slack. 4) Vibration Dampening: Materials that absorb and dampen vibrations lead to smoother operation and less wasted energy. These factors contribute to lower fuel consumption and greater overall operational efficiency of the machinery.

Q7: Can a single **emergency serpentine belt** replace multiple belts in a modern diesel engine?

A: Yes, in modern diesel engines, a single **emergency serpentine belt** (also known as a multi-ribbed V-belt or accessory drive belt) often replaces what traditionally would have been multiple individual V-belts. This design simplifies the accessory drive system, reduces overall weight, and improves efficiency by using a single, long belt to drive various components like the alternator, power steering pump, water pump, and air conditioning compressor. While it simplifies the system, it also means a single belt failure can disable multiple accessories, underscoring the importance of its reliability and regular inspection.

The Future of Power Transmission: Innovation in **Diesel Engine Belts**

The evolution of the **diesel engine belt** is far from complete. As industries demand higher efficiency, reduced environmental impact, and increased automation, the future of power transmission belts holds exciting innovations:

- Smart Belts with Integrated Sensors: Expect to see more belts with embedded sensors for real-time monitoring of tension, temperature, speed, and even wear. These "smart belts" will integrate with predictive maintenance systems, providing data-driven insights to prevent failures and optimize replacement schedules for components like the **tensioner fan belt** or **engine accessory drive belt**. This marks a significant shift from reactive to proactive maintenance.

- Further Material Breakthroughs: Research into even more advanced polymer composites and cord materials will continue to push the boundaries of temperature resistance, chemical inertness, and strength-to-weight ratios. This will enable belts to operate reliably in increasingly extreme environments and under heavier loads, extending the service life of every **diesel engine belt**.

- Enhanced Sustainability: Manufacturers are increasingly focused on eco-friendly production processes and materials. This includes using recycled content where possible, developing more energy-efficient manufacturing techniques, and designing belts that are easier to recycle at the end of their lifespan, contributing to a circular economy.

- Advanced Profile Designs: Ongoing research into belt and pulley interface dynamics will lead to even more efficient and quieter profiles, further reducing friction losses and extending the life of both the belt and the **tensioner belt pulley** it engages with.

- Integration with Electrification: As hybrid and electric heavy machinery gains traction, belts will evolve to support these new power architectures, potentially playing a role in power take-off (PTO) systems or specialized accessory drives that integrate with electric motors.

These innovations underscore the continuous drive for excellence in the **diesel engine belt** sector, promising even more reliable, efficient, and intelligent solutions for the industrial world. The foundation laid by products like the Drive Belt VOE21620132 10PK Belt For Volvo Construction Equipment Excavator Parts EC240, EC340D sets the stage for these exciting future developments.

Partner with Us for Unrivaled Performance

The operational efficiency and longevity of your heavy machinery are directly influenced by the quality of its components. When it comes to power transmission, settling for anything less than a high-performance **diesel engine belt** is a compromise you cannot afford. At Hawkbelt, we are dedicated to manufacturing and supplying top-tier **diesel engine belts** that meet and exceed the most stringent industry demands.

Our flagship product, the Drive Belt VOE21620132 10PK Belt For Volvo Construction Equipment Excavator Parts EC240, EC340D, exemplifies our commitment to engineering excellence, offering unparalleled durability, efficiency, and reliability for your critical Volvo equipment. Whether you require a robust **tensioner fan belt**, a precise **engine accessory drive belt**, or a dependable **emergency serpentine belt**, our expertise ensures you receive the optimal solution.

Choose Hawkbelt for products built on a foundation of deep expertise, extensive experience, undisputed authoritativeness, and unwavering trustworthiness. Empower your operations with belts designed for tomorrow's challenges, ensuring maximum uptime and superior performance for your valuable assets. Contact us today to discuss your specific requirements and discover how our advanced **diesel engine belts** can drive your success forward.

References & Further Reading

- "Global Industrial Belts Market Report 2023-2028." Research and Markets. Available at: https://www.researchandmarkets.com/reports/5888267/global-industrial-belts-market-report-2023-2028 (Accessed [Current Date, e.g., October 26, 2023])

- Hussain, S. A., & Ahmad, N. M. (2019). "Recent Advances in Elastomeric Materials for Automotive Applications." Journal of Engineering Science and Technology Review, 12(6), 1-10. Available at: https://jestr.org/downloads/Volume12Issue6/paper1.pdf (Accessed [Current Date, e.g., October 26, 2023])

- ISO 9001:2015. "Quality management systems — Requirements." International Organization for Standardization. Available through official ISO channels. (General standard reference)

- "The Role of Belts in Modern Diesel Engine Efficiency and Emissions." SAE International (Society of Automotive Engineers) Technical Papers. Available via SAE Digital Library (subscription required, but public abstracts available). Example: https://www.sae.org/publications/technical-papers/content/970795/ (Accessed [Current Date, e.g., October 26, 2023])

- RMA IP-20. "Specifications for V-Ribbed Belts." Association for Rubber Products Manufacturers (ARPM, formerly RMA). Available through ARPM publications. (General standard reference)

This is the last article

-

Reliable Diesel Engine Belts & Tensioners for Optimal Performance

NewsAug.07,2025

-

23100-KVB-901 Drive Belt for Honda VARIO | OEM Performance

NewsAug.06,2025

-

Variable Belt Drive AI Optimized for Efficiency

NewsAug.05,2025

-

High-Quality Tensioner Belt Pulley - Durable & Efficient

NewsAug.03,2025

-

Premium Timing Belt Factory | AI-Optimized Solutions

NewsAug.02,2025

-

Heat Joining Drive Belt | High-Durability Fusion Solution

NewsJul.31,2025